Creep deformation type hot melt rubber asphalt waterproof paint

A technology of rubber asphalt and waterproof coatings, applied in the direction of asphalt coatings, coatings, etc., can solve the problems of easy flow and low strength, and achieve the effects of good high temperature resistance, excellent low temperature flexibility, and good creep properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 provides the producer of raw material in the embodiment

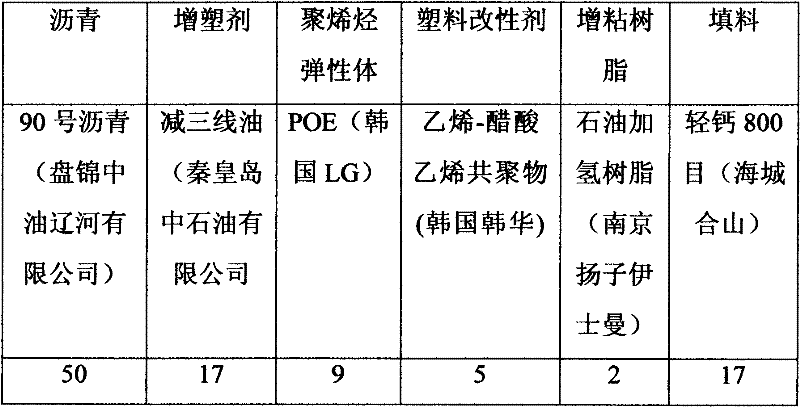

[0026] Proportioning (weight ratio, the same below) of creep type hot-melt rubber asphalt waterproof coating raw materials according to the following (Table 1):

[0027] Table 1 Creep-type hot-melt rubber asphalt waterproof coating formula table

[0028]

[0029] The manufacturing process of creep-type hot-melt rubber asphalt waterproof coating is as follows:

[0030] a. Heat the asphalt to 130-160°C for later use;

[0031] b. Add plasticizer and tackifying resin to asphalt at 130-160°C, stir at low speed for half an hour;

[0032] c. Increase the temperature to 180-200°C, add POE and ethylene-vinyl acetate copolymer, and start the colloid mill, and stir for about 1-2 hours until the modifier is completely melted;

[0033] d. Keep the temperature at 160-180°C, add filler and stir for 30-50 minutes until the particles are evenly dispersed;

[0034] e. Cool down to 140-160°C and discharge.

Embodiment 2

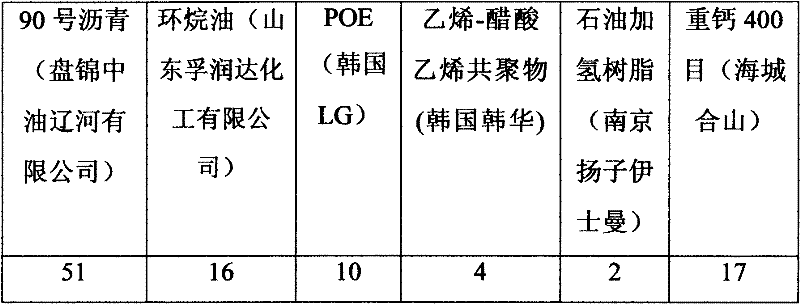

[0036] Proportioning (weight ratio, the same below) of creep type hot-melt rubber asphalt waterproof coating raw materials according to the following (Table 2):

[0037] Table 2 Creep-type hot-melt rubber asphalt waterproof coating formula table

[0038]

[0039]

[0040] The manufacturing process of the creep type hot-melt rubber asphalt waterproof coating in Example 2 is as in Example 1.

Embodiment 3

[0042] The raw materials of creep type hot melt rubber asphalt waterproof coating are proportioned according to the following (Table 3) (weight ratio, the same below):

[0043] Table 3 Creep-type hot-melt rubber asphalt waterproof coating formula table

[0044]

[0045] The manufacturing process of the creep type hot-melt rubber asphalt waterproof coating in Example 3 is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com