Steel belt connecting device and method

A technology of connecting device and steel strip, applied in the direction of thin plate connection, connecting member, mechanical equipment, etc., can solve the problems of low tensile strength of welding surface, long welding operation time, affecting unit operation rate, etc., and achieve high tensile strength, Improve the success rate, the effect of convenient and fast steel belt connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, the present invention will be described in detail with reference to the accompanying drawings.

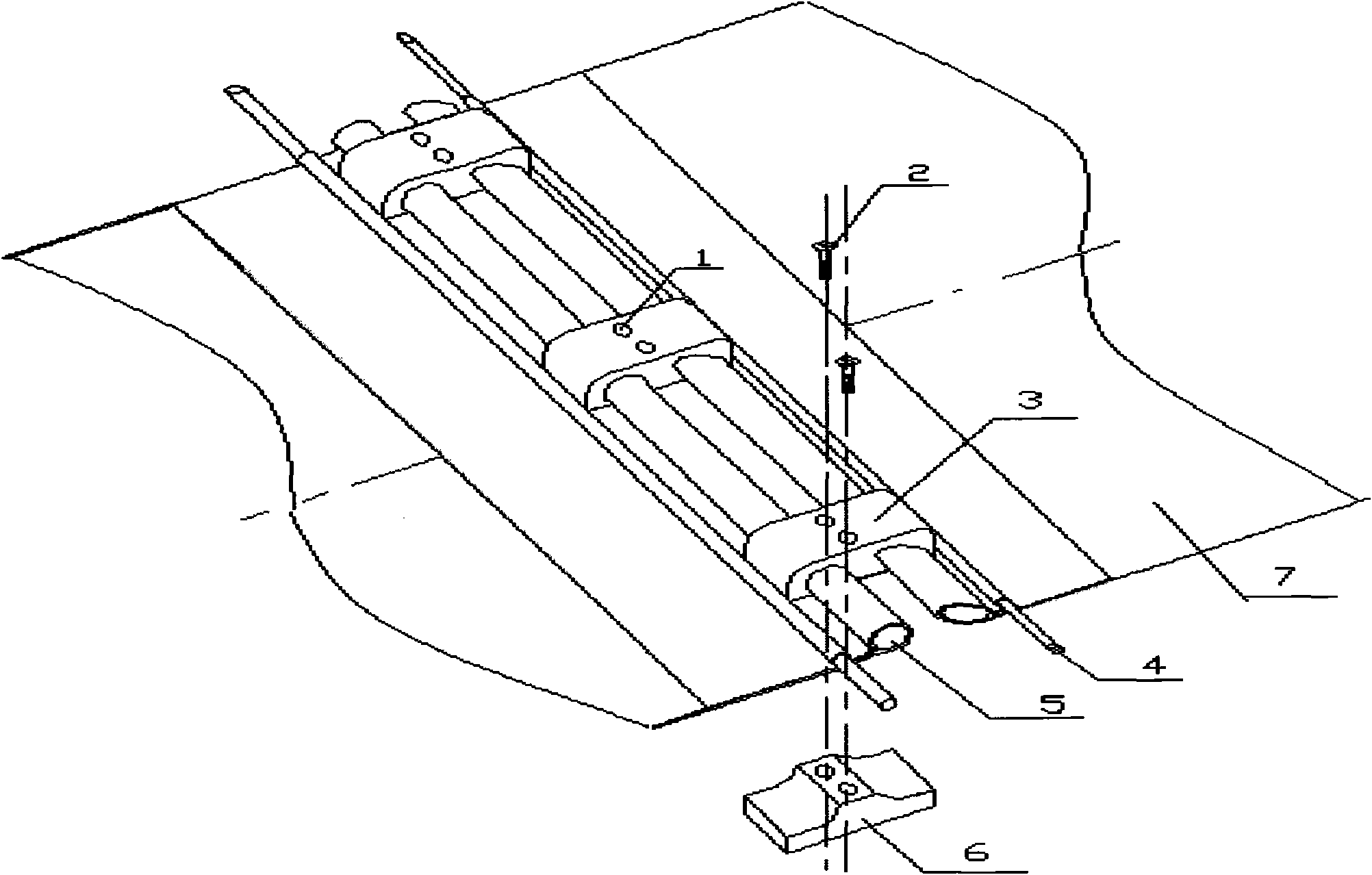

[0033] figure 1 It is a three-dimensional view of the use state of the steel belt connection device, which is represented by figure 1 It can be seen that the steel belt connecting device of the present invention includes a countersunk screw 2 , an end cover 3 , an anti-loosening rod 4 , a reinforcing round steel 5 and a base 6 . Wherein the single countersunk screw 2, the end cover 3 and the base 6 together form a jig.

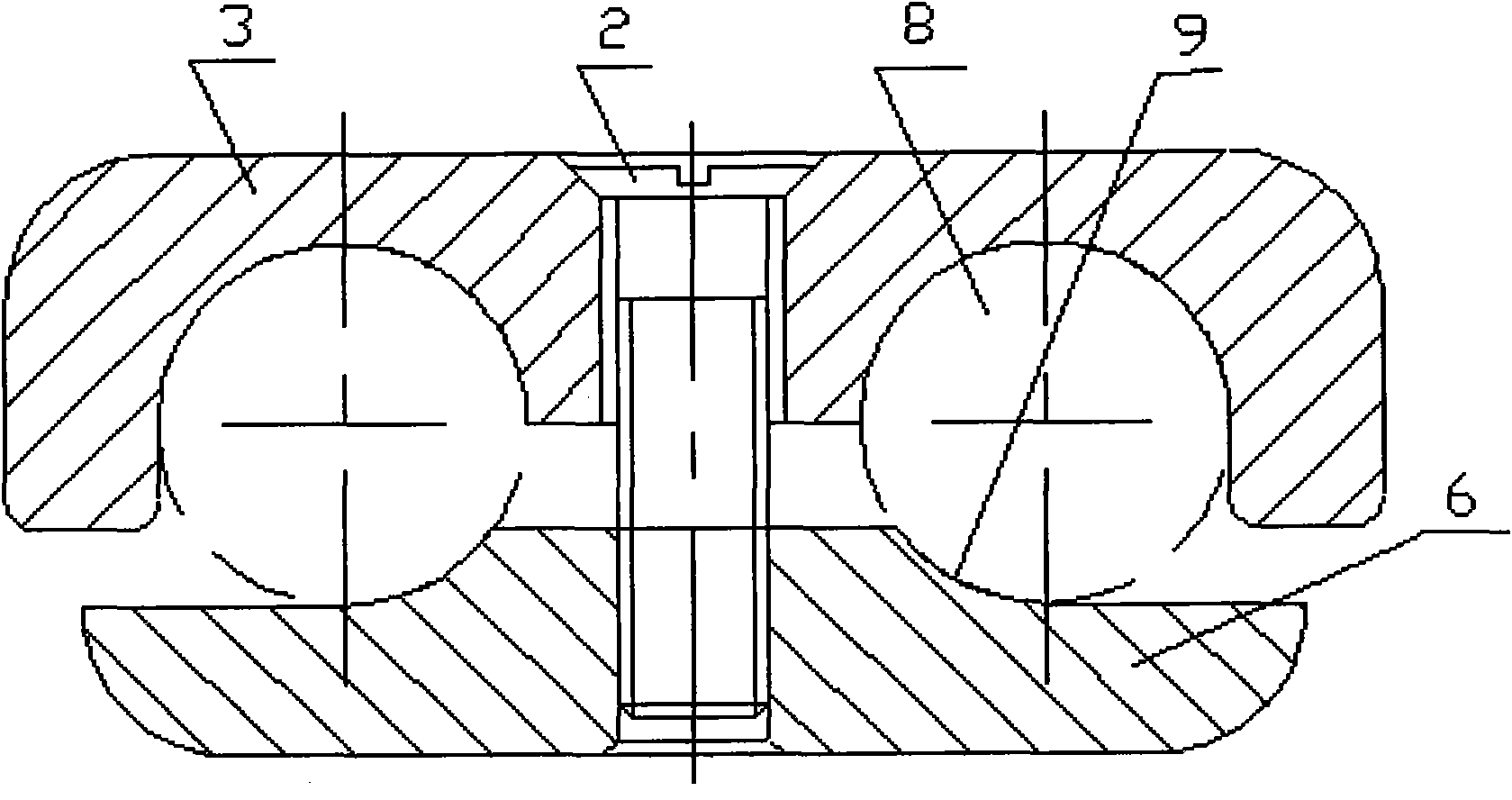

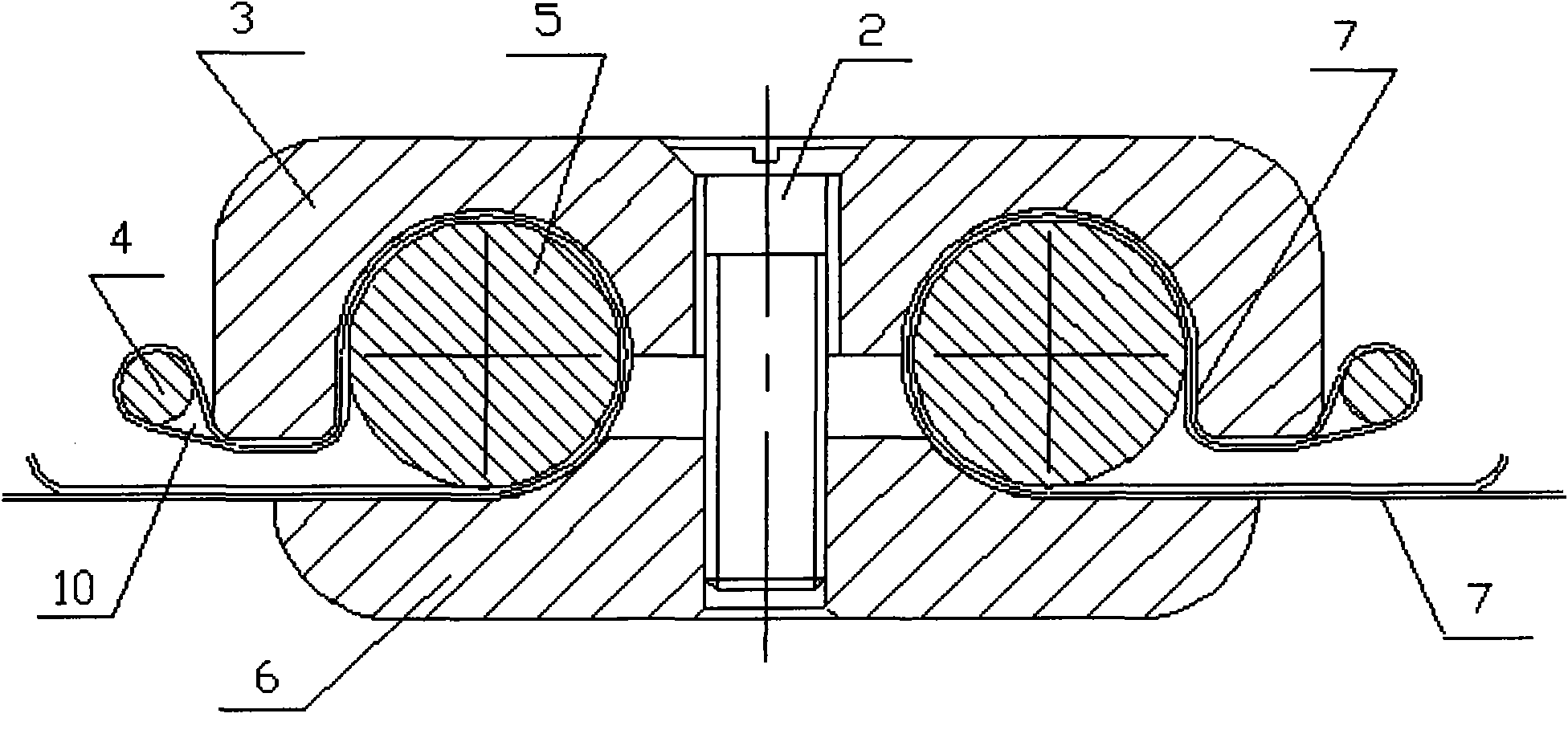

[0034] Fixture Sectional View figure 2 It shows that two semicircular draw-in grooves 8 are processed on the bottom surface of the end cover 3, and the outside of the draw-in groove 8 with a straight section (that is, the outside of the end cover 3) is longer than the inside of the draw-in groove 8; 3 is fastened on a base 6 with a boss in the middle, and both sides of the boss of the base 6 have transition arcs 9. Two screw holes 1 are arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com