Direct-current voltage balancing plate for modular active filter

A technology of DC voltage equalization and source filter, which can reduce harmonics/ripples and other directions when applied to DC circuits, and can solve problems such as simplification, damage to devices, and fires, and achieve the effect of improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

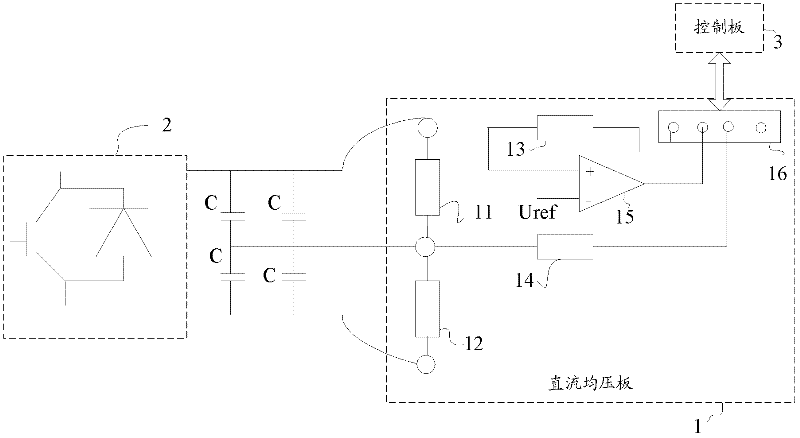

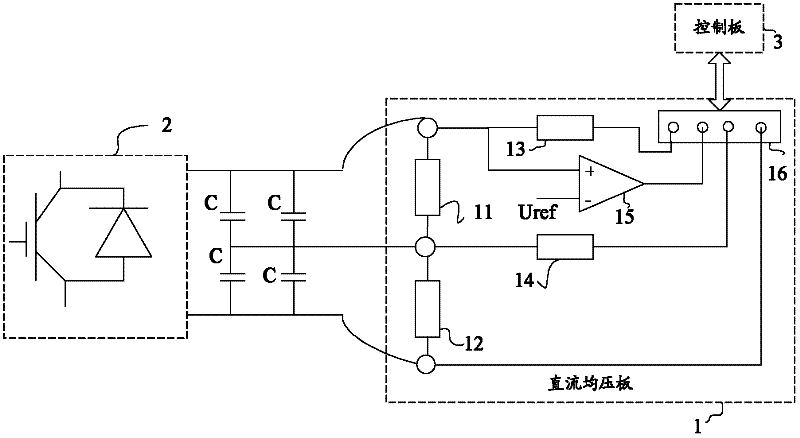

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] see figure 1 , the DC equalizing board for modular active filter of the present invention, wherein the active filter includes an IGBT module 2 with two DC bus bars and several series branches connected in parallel between the DC bus bars, each The series branch is divided into two parts connected in series, the series connection point of the two parts is called the midpoint of the series branch, and each part is composed of n / 2 capacitors C connected in series, n is a positive even number;

[0023] In this embodiment, n=2, and there are only two series branches, that is, a total of 4 capacitors C, and every two capacitors C are connected in parallel after being connected in series, as figure 1 ;

[0024] The DC grading board 1 includes a first grading resistor 11, a second grading resistor 12, a first signal converting resistor 13, a second signal converting resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com