Device for simultaneously scorching at multiple sections in catalyst device of fixed bed reactor and process thereof

A fixed-bed reactor and catalyst technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc. Inactivation and other problems, to achieve the effect of shortening the scorching time, monitoring the oxygen content, and reducing the energy consumption of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

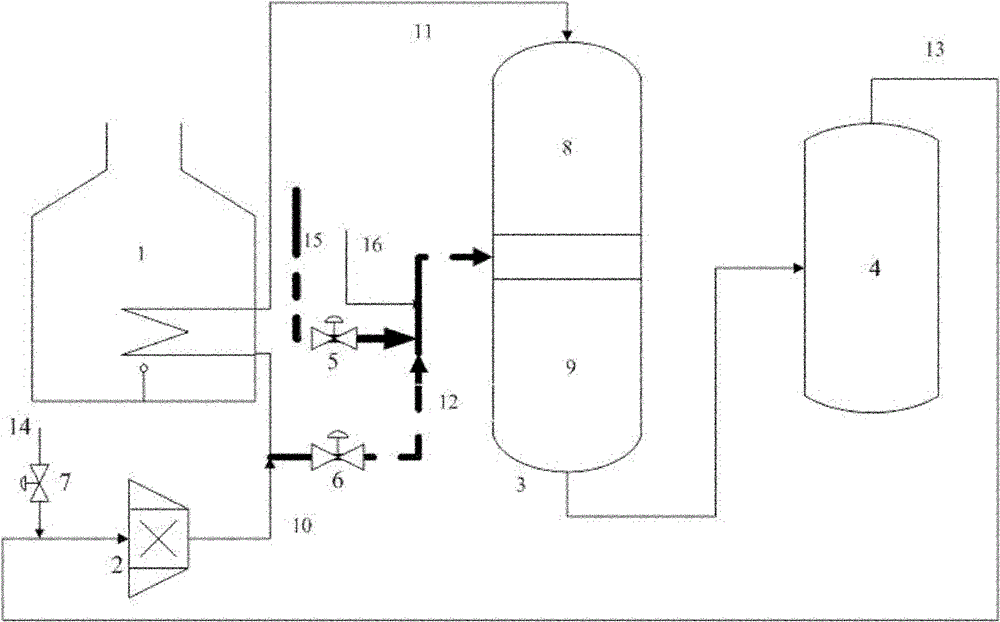

[0028] The multi-stage simultaneous coking device in the fixed bed multi-bed reactor catalyst includes a heating furnace, a regeneration cycle gas compressor, a catalyst reactor, a regeneration cycle gas liquid separation tank, an online oxygen analyzer and a regulating valve. There are two A catalyst bed is divided into an upper bed 8 and a lower bed 9, and a pipeline C12 communicated with the pipeline A10 is set between the outlet pipeline A10 of the regeneration cycle gas compressor and the inlet of the lower bed 9, and a pipeline C12 connected with the pipeline C12 is arranged on the pipeline C12. Connected make-up compressed air line F15. A regenerative circulating air regulating valve 6 and a compressed air regulating valve A5 are respectively provided at the inlet end of the pipeline C12 and the outlet end of the supplementary compressed air pipeline F15. The online oxygen analyzer is set between the connection between the supplementary compressed air line F15 and the l...

Embodiment 2

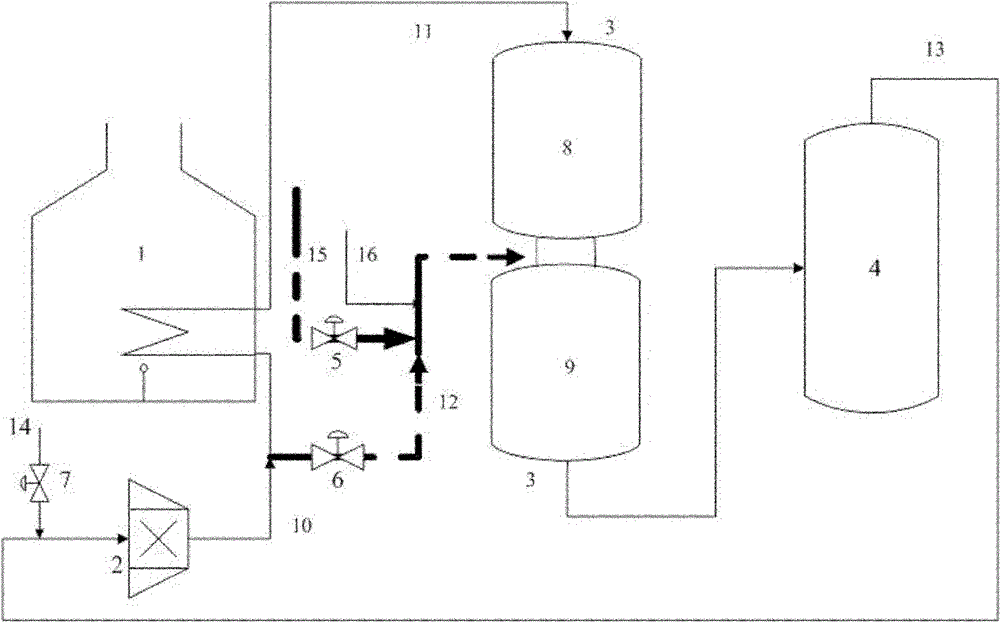

[0047] The multi-stage simultaneous coking device in multiple fixed-bed catalyst reactors in series includes a heating furnace, a regeneration cycle gas compressor, a catalyst reactor, a regeneration cycle gas liquid separation tank, an online oxygen analyzer and a regulating valve, reactor A and reactor B In series, there are single beds in the reactor, which are respectively bed 8 and bed 9, and a pipeline C12 connected with pipeline A10 is set between the outlet pipeline A10 of the regeneration cycle gas compressor and the inlet of bed B. C12 is provided with a make-up air pipeline F15 communicating with it. Flow control valves are respectively provided at the inlet end of the pipeline C12 and the outlet end of the supplementary air pipeline F15. The online oxygen analyzer is set between the connection between the air supply line F15 and the line C12 and the inlet of the bed B.

[0048] The coking process and related process parameters, time and consumption of the multi-st...

Embodiment 3

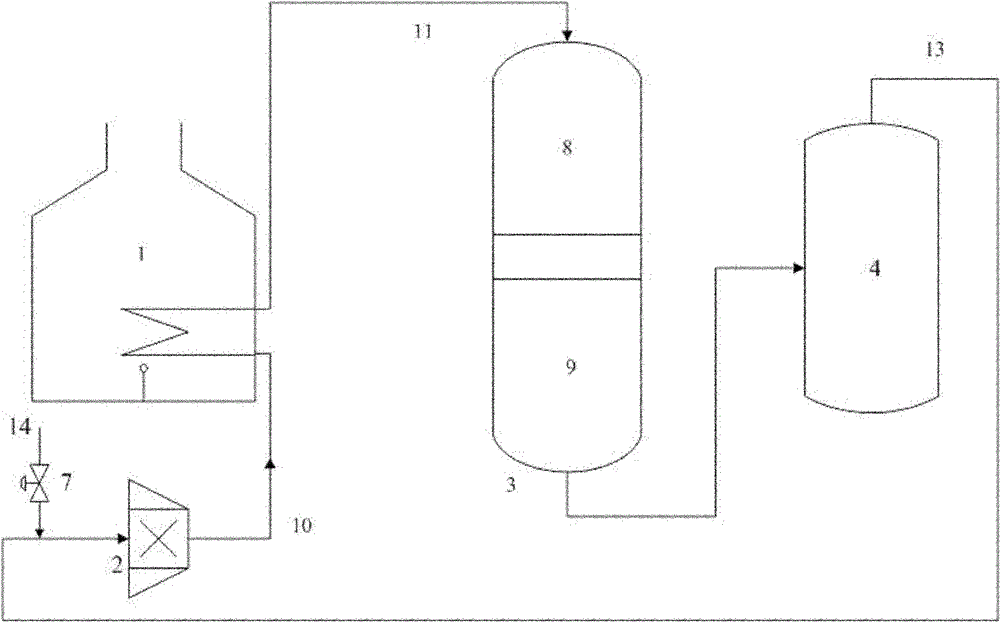

[0050] The fixed-bed multi-bed reactor catalyst regeneration coking device includes a heating furnace, a regeneration cycle gas compressor, a catalyst reactor, a regeneration cycle gas liquid separation tank and a regulating valve.

[0051] The coke regeneration process in the fixed-bed multi-bed reactor catalyst includes the following steps:

[0052] (1) Start the regenerative cycle gas compressor, fill it with nitrogen from its inlet, and increase the pressure to 0.3MPa-0.4MPa;

[0053] (2) The heating furnace is ignited and heated up, and the system is replaced with hot nitrogen, and the temperature is raised to 395-405 °C at the outlet of the heating furnace;

[0054] (3) Open the compressed air regulating valve B7 to replenish compressed air from the inlet of the regenerated circulating air compressor, start to burn from the top of the reactor, and control the oxygen content to be about 0.5%, which is the first stage of burning;

[0055] (4) When the temperature of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com