Method for machining valve seat of respiratory flow and rhythm control air valve

A breathing flow and air valve control technology, which is applied to the breathing flow rhythm control air valve seat and its processing field, can solve the problems of large valve seat coaxiality error, numerous processing steps, poor precision control, etc., and achieves processing accuracy. Guaranteed, wide processing range, reduced processing program effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

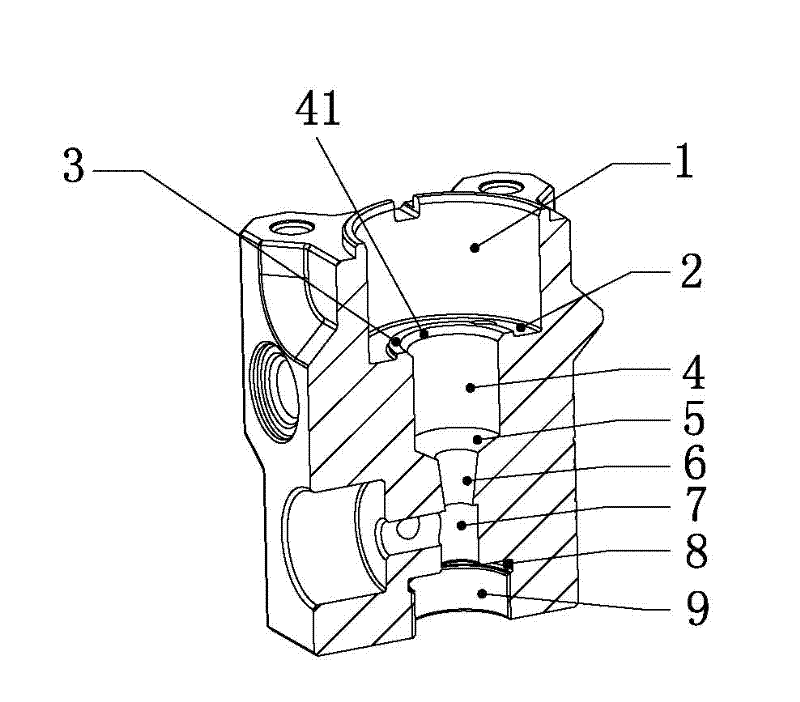

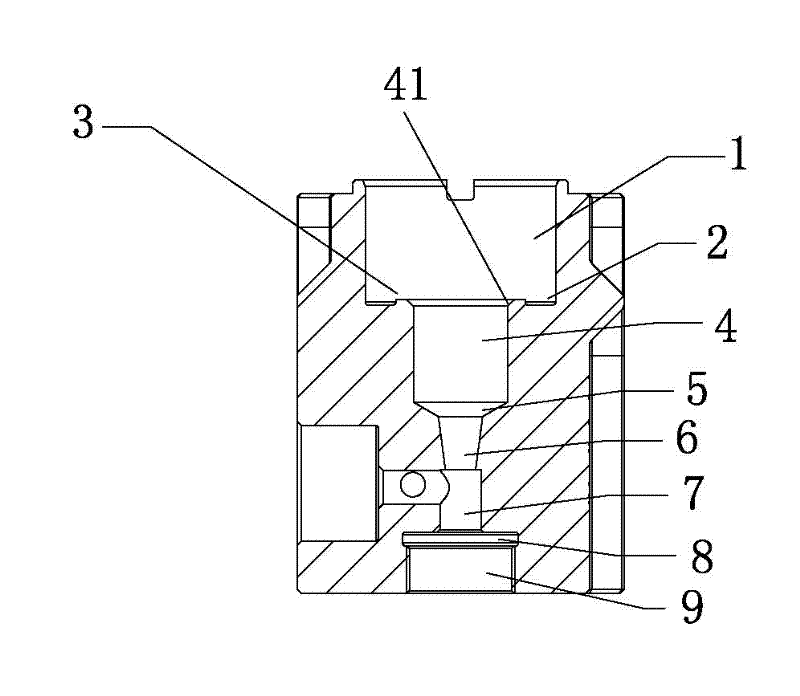

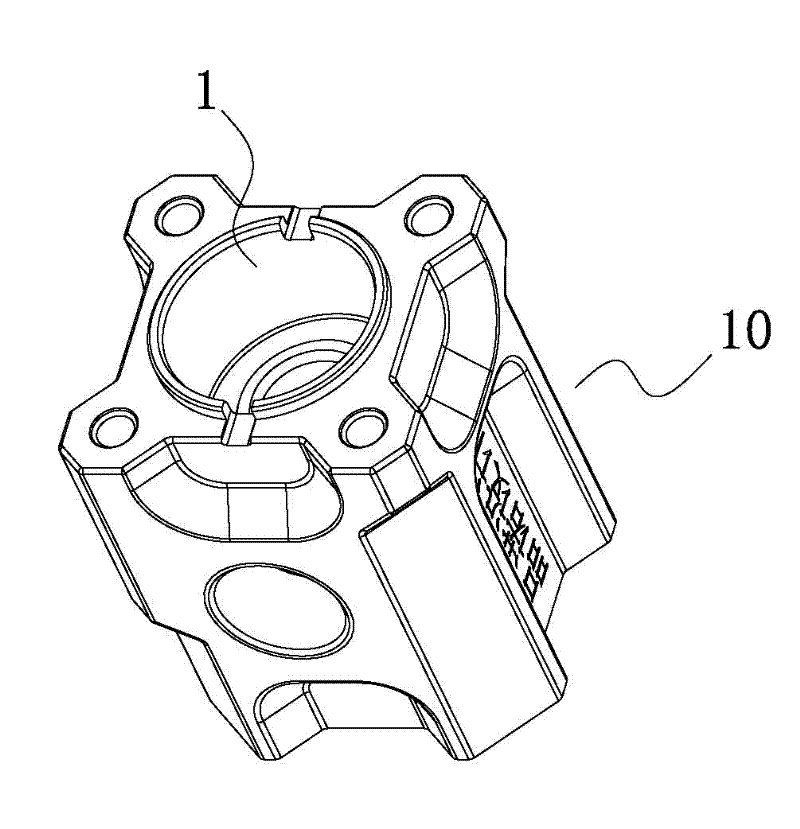

[0024] Such as Figure 1-4 As shown, a valve seat processing method of a breathing flow rhythm control air valve of the present invention is characterized in that: the inner cavity of the valve seat is composed of an upper inner cylindrical surface 1, an inner end surface 2, a stepped surface 3, a middle inner cylindrical surface 4, The upper conical surface 5, the lower conical surface 6, the lower inner cylindrical surface 7, the inner retracting ring groove 8, and the threaded surface 9 are sequentially connected, and the upper inner cylindrical surface 1, the inner end surface 2, the stepped surface 3, and the middle inner cylindrical surface 4. The axis lines of the upper conical surface 5 and the lower conical surface 6 are all on the same central axis; the inner cavity of the valve seat is processed on a CNC lathe, including the following steps in turn:

[0025] 1) Process the metal raw material and turn it into a cylindrical valve seat blank, remove the cylindrical val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com