Production method of polymide

A technology of polyimide and manufacturing method, applied in the field of polyimide manufacturing, can solve the problems of polyimide washing off, poor water resistance of polyimide, etc., and achieve the effect of sufficient chemical reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

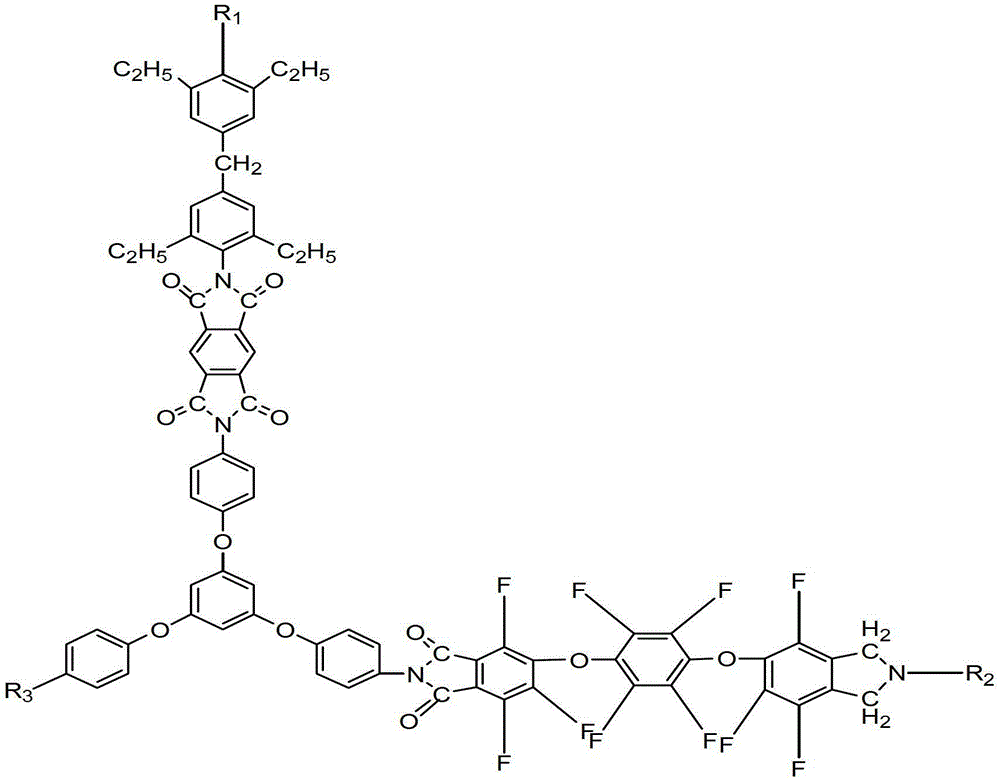

[0018] The present invention proposes a washing-resistant polyimide manufacturing method, which is described in detail as follows.

[0019] Described polyimide manufacture method embodiment comprises the steps:

[0020] S1: Take dimethylformamide (DMF) and dissolve 4,4-diaminodiphenyl ether (ODA) with a molar mass percentage of 60%-70% of the total amines, and keep the solution temperature stable at 10-25°C;

[0021] S2: adding pyromellitic dianhydride (PMDA) accounting for 10%-30% of the total anhydride molar mass percentage to the solution at least twice, with an interval of at least 2 hours each time;

[0022] S3: After adding pyromellitic dianhydride (PMDA), add 3,3',5,5'-tetraethyl-4,4'-di Aminodiphenylmethane (3,5-TEMDA) reacted;

[0023] S4: After adding 3,3',5,5'-tetraethyl-4,4'-diaminodiphenylmethane (3,5-TEMDA) in the previous step for at least 2 hours, the concentration of the total anhydride mass percentage is 10%-15% of perfluoro-1,4-diphthalic anhydride benzen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com