PP (polypropylene)/ABS (acrylonitrile-butadiene-styrene copolymer) alloy material as well as preparation method and application thereof

A technology of alloy materials and mixtures, applied in the field of PP/ABS alloy materials, can solve the problems of uneven dispersion of flame retardants and poor flame retardant performance, and achieve the effect of excellent mechanical properties and flame retardant performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

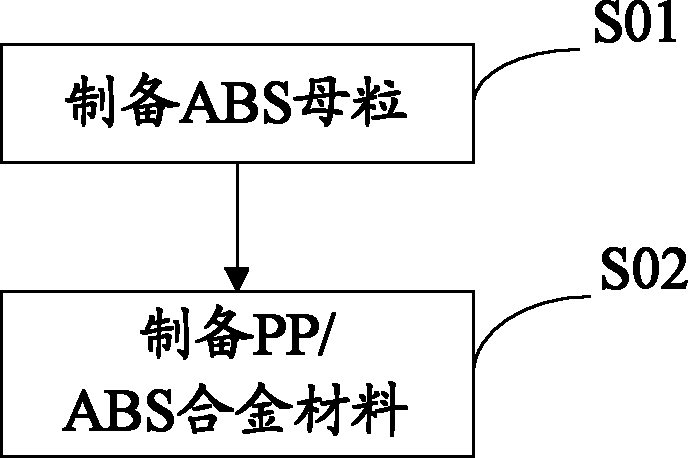

[0018] see figure 1 , figure 1 Show the flow chart of the method for preparing the PP / ABS alloy material of the embodiment of the present invention, including the following steps:

[0019] Step S01, preparing ABS masterbatch:

[0020] ABS, phosphorus-containing flame retardant, and antioxidant are mixed to obtain a first mixture, and the first mixture is extruded to obtain an ABS masterbatch, and the parts by weight of each component in the first mixture are as follows:

[0021] ABS 50~90 parts

[0022] Phosphorus-containing flame retardant 10-50 parts

[0023] Antioxidant 0.1 to 2 parts;

[0024] Step S02, preparing PP / ABS alloy material

[0025] Mix polypropylene, compatibilizer, the ABS masterbatch, phosphorus-nitrogen-containing flame retardant, and antioxidant to obtain a second mixture, and extrude the second mixture to obtain a PP / ABS alloy material. The parts by weight of each component in the second mixture are as follows:

[0026]

[0027] The preparation m...

Embodiment 1

[0047] The preparation method of the PP / ABS alloy material of the embodiment of the present invention comprises the following steps:

[0048] Mix ABS, phosphorus-containing flame retardants, and antioxidants to obtain a first mixture, and extrude the first mixture at a temperature of 160°C to obtain ABS masterbatches, and each component in the first mixture The parts by weight are as follows:

[0049]

[0050]mixing polypropylene, compatibilizer, the ABS masterbatch, phosphorus-nitrogen-containing flame retardant, and antioxidant to obtain a second mixture, and extruding the second mixture at a temperature of 170°C to obtain PP / ABS alloy material, the parts by weight of each component in the second mixture are as follows:

[0051]

Embodiment 2

[0053] The preparation method of the PP / ABS alloy material of the embodiment of the present invention comprises the following steps:

[0054] Mix ABS, phosphorus-containing flame retardants, and antioxidants to obtain a first mixture, and extrude the first mixture at a temperature of 170°C to obtain ABS masterbatches, and each component in the first mixture The parts by weight are as follows:

[0055]

[0056]

[0057] mixing polypropylene, compatibilizer, the ABS masterbatch, phosphorus-nitrogen-containing flame retardant, and antioxidant to obtain a second mixture, and extruding the second mixture at a temperature of 180°C to obtain PP / ABS alloy material, the parts by weight of each component in the second mixture are as follows:

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com