Refined slag used in steel-making process for bearing steel

A technology of refining slag and bearing steel, which is applied in the field of bearing steel smelting technology, can solve the problems of unsatisfactory control effect of B-type inclusions in steel, affecting the performance of bearing steel, desulfurization effect and other problems, achieving strong adsorption capacity and improving quality , the effect of fast slag formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with embodiment.

[0024] With CaO, Al 2 o3 , SiO 2 , MgO and Al components such as (highly active metallurgical lime, calcium aluminate pre-melted slag, wollastonite, dolomite and metallic aluminum) are made into 10 after crushing→batching→mixing→forming→drying and other processes -40mm size and shape, add ladle during electric furnace / converter tapping and LF refining process, adding amount is 15-20kg / t.s.

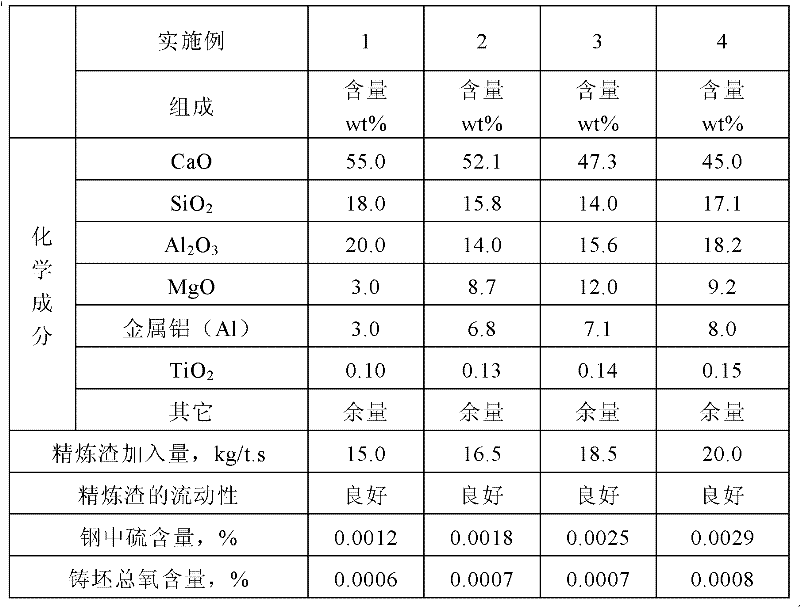

[0025] Four kinds of refining slags for bearing steel were used to test, and their compositions and application effects are shown in Table 1. It can be seen from the table that by adopting the refining slag for bearing steel of the present invention, the total oxygen content and sulfur content of the bearing steel can reach a good level.

[0026] Table 1

[0027]

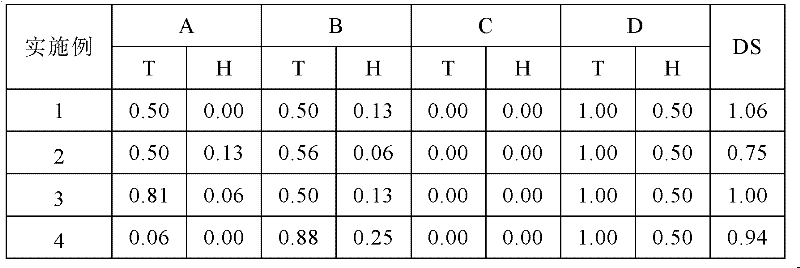

[0028] Table 2 shows the improvement effect of the four groups of bearing steel refining slags in Table 1 on the coarse and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com