Yttrium alloy super heat-conducting material and super heat-conducting device

A technology of superconducting heat and alloys, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of complex manufacturing process, high manufacturing cost, and low production efficiency, and achieve simple manufacturing process and low manufacturing cost. The effect of low cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

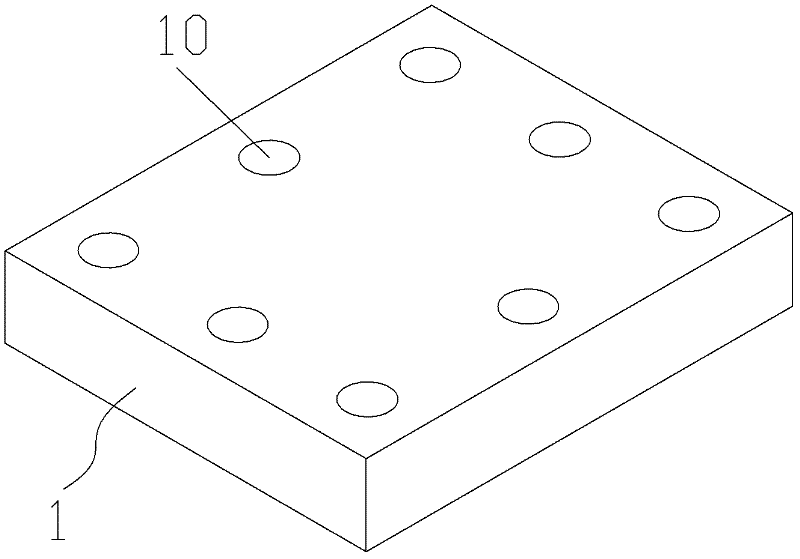

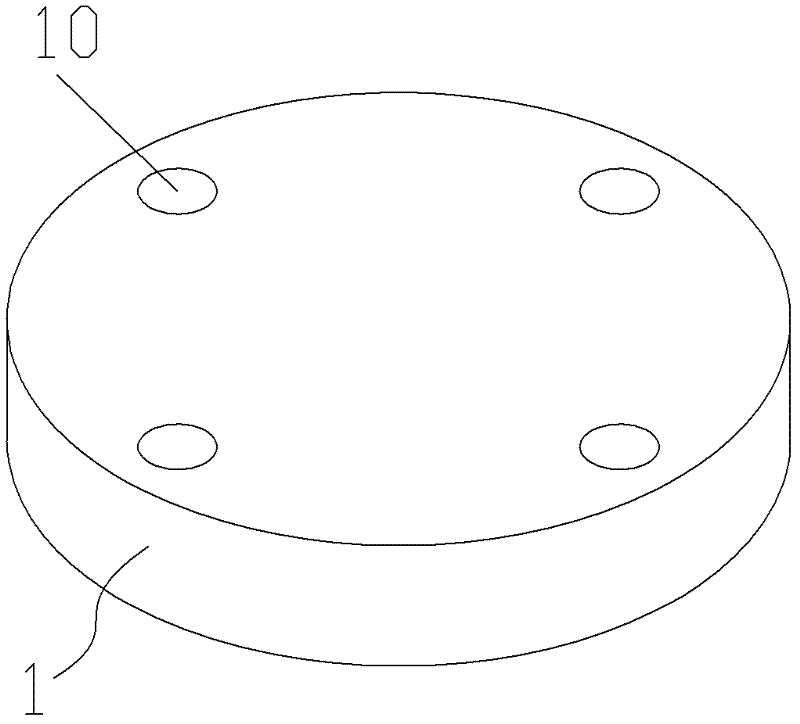

[0014] Proportioning: 15% yttrium, 15% scandium, and 70% aluminum are the ratio of raw materials to produce and process superconducting thermal materials according to conventional alloy manufacturing processes, and according to requirements, adopt the above-mentioned yttrium alloy superconducting thermal materials to produce such as figure 1 or figure 2 The superconducting thermal device 1 shown.

Embodiment 2

[0016] According to the ratio: 10% yttrium, 5% titanium, 5% molybdenum, 15% scandium, and 65% aluminum are used as raw materials to produce and process superconducting thermal materials according to conventional alloy manufacturing processes, and use the above-mentioned yttrium alloy superconducting thermal materials as required According to conventional alloy processing technology, such as figure 1 or figure 2 The superconducting thermal device 1 shown.

Embodiment 3

[0018] According to the ratio: 5% yttrium, 5% scandium, 2% vanadium, 5% strontium, 3% beryllium, and 80% aluminum are used as raw material ratios to produce and process superconducting thermal materials according to conventional alloy manufacturing processes, and use the above-mentioned yttrium alloy super The heat conduction material is produced according to the conventional alloy processing technology such as figure 1 or figure 2 The superconducting thermal device 1 shown.

[0019] The thermal superconducting device 1 has a regular rectangular parallelepiped or cylindrical block structure, and several through holes 10 are opened on the thermal superconducting device 1 to increase air convection, thereby improving heat dissipation performance.

[0020] When in use, the upper surface of the superconducting thermal device 1 is used as a heating surface for installing solar photoelectric modules or ultra-high-power LED modules, etc., and the lower surface can be connected to h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com