Fuel oil system of ship

A technology for fuel oil and fuel oil, which is applied to combustion engines, internal combustion piston engines, engine control, etc., can solve the problems of large investment, bulkiness, and sulfur oxide emissions of sulfur treatment devices, and achieve good economic and social benefits. System Simple, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

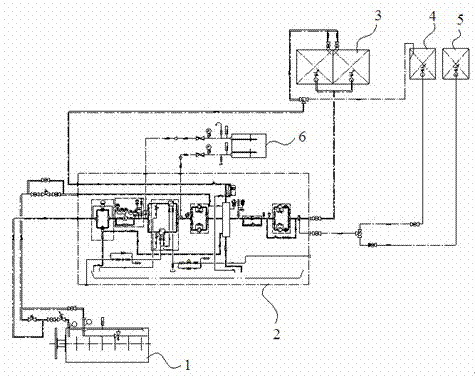

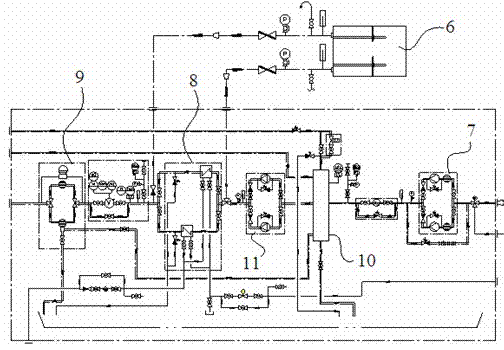

[0010] Below in conjunction with specific accompanying drawing, the utility model is further explained.

[0011] Such as figure 1 with figure 2 As shown, the marine fuel oil system includes a main engine 1, a low-sulfur oil tank 5, a diesel tank 4 and a heavy oil tank 3; the main engine 1 is connected to the oil supply unit 2 through an oil circuit; the low-sulfur fuel tank 5, the diesel tank 4 and The heavy oil tank 3 is connected with the oil supply unit 2 through an oil circuit. The fuel supply unit 2 includes a low-sulfur oil cooler 6 , a fuel supply pump 7 , a fuel heater 8 , a fuel self-cleaning filter 9 , a fuel oil return cylinder 10 and a fuel circulation pump 11 . One end of the fuel supply pump 7 is connected to the fuel oil return tank 10, and the other end is connected to the low-sulfur oil tank 5, the diesel tank 4 and the heavy fuel tank 3 respectively; The oil tank 10 is provided with a circuit connected to the fuel circulation pump 11, the fuel heater 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com