Multi-station synchronous test system for testing quartz crystal oscillator by continuously raising temperature

A quartz crystal, synchronous testing technology, applied in the direction of instruments, measuring electricity, measuring devices, etc., can solve the problems of measurement efficiency limitation, reliability impact, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

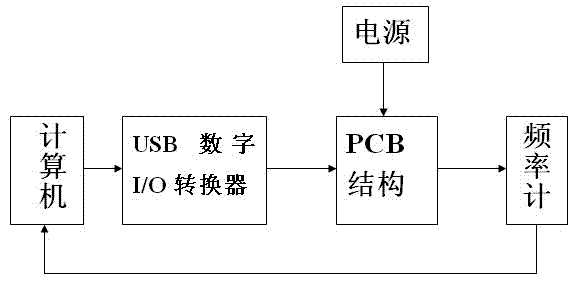

Method used

Image

Examples

Embodiment

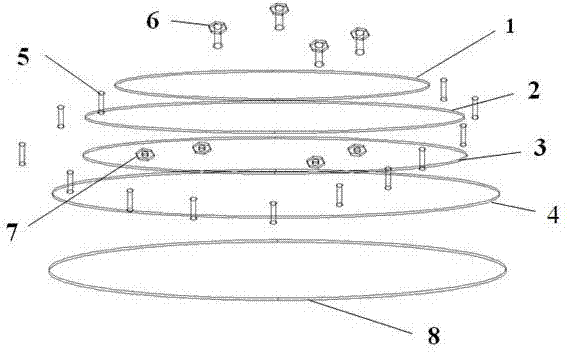

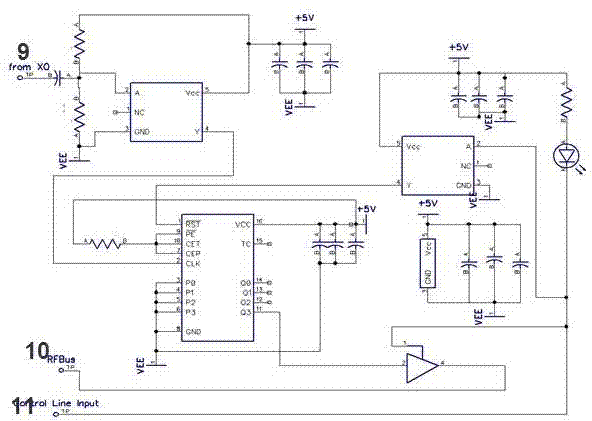

[0021] in the attached figure 2 The top layer PCB board for pressing the quartz crystal oscillator 1, the third layer PCB board for fixing the quartz crystal oscillator 2, the second layer PCB board for positioning nuts and protection probes 3, the circuit signal for 80 oscillators of the same type are placed on a set of PCB boards composed of the bottom PCB board 4 for transmission and control, and then the attached figure 2 The top layer PCB board for pressing the quartz crystal oscillator 1, the third layer PCB board for fixing the quartz crystal oscillator 2, the second layer PCB board for positioning nuts and protection probes 3, the circuit signal for The bottom PCB board 4 for transmission and control is combined into a set of signal control lines, power lines, frequency output lines and figure 2 The signal control PCB total board 8-phase connection, figure 2 The signal control PCB total board 8 in the can be connected simultaneously by the attached figure 2 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com