Method for improving quality of tobacco stalks by using grape wine

A technology for wine and tobacco stems, which is applied in the directions of tobacco, application and treatment of tobacco, can solve the problems of reducing the quality of tobacco stems smoking, large woody odors, and high irritation, and achieves good application prospects, reduces irritation, and improves aftertaste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

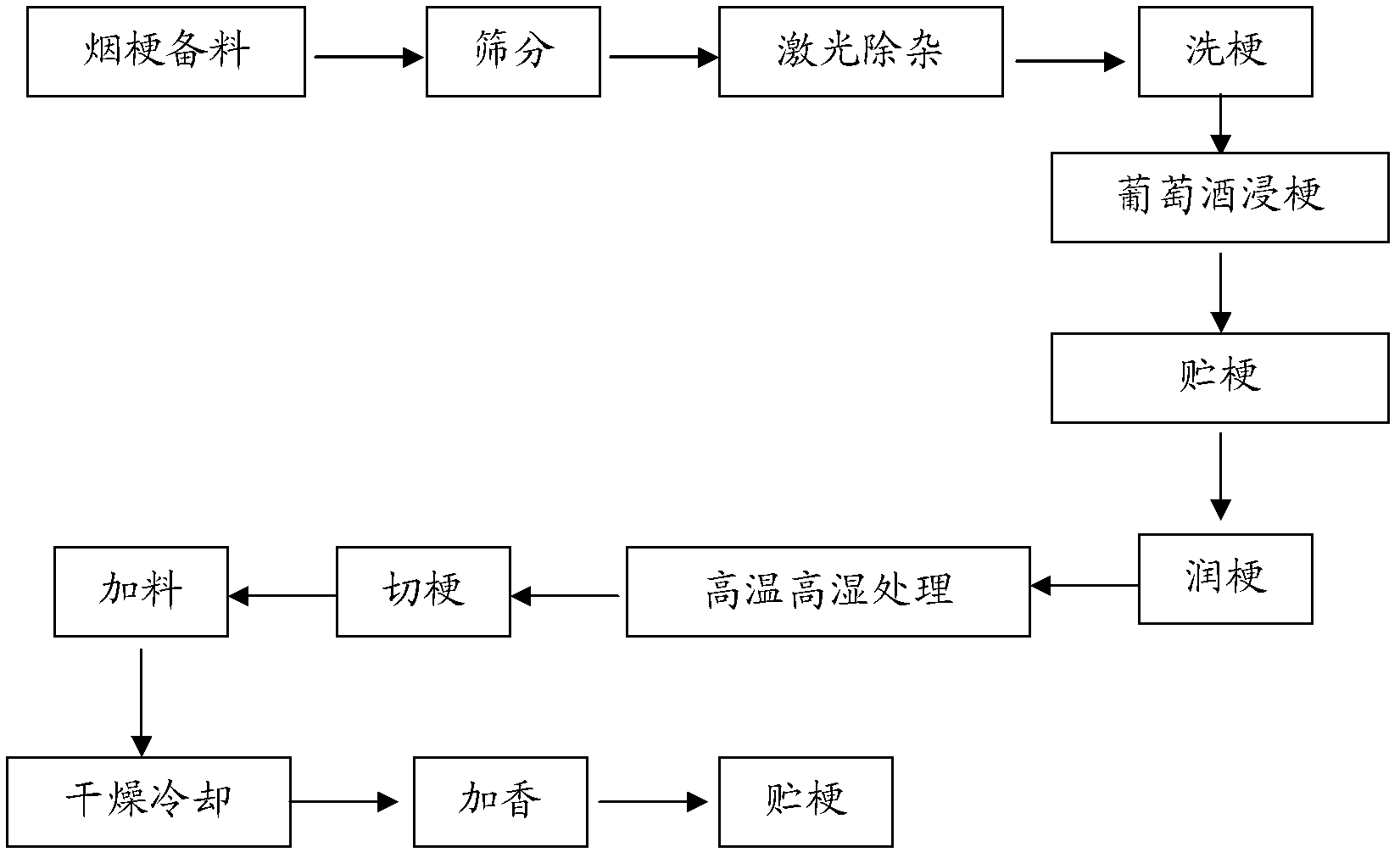

Method used

Image

Examples

Embodiment 1

[0016] Pour 40L of red wine with an alcohol content of 11°, 10L of propylene glycol, 10L of sorghum wine with an alcohol content of 50°-55°, and 40L of purified water into a pool with a volume of 250L, and stir the poured solution evenly, and place 2h. Then pour 100 kg of flue-cured tobacco stem strips with a water content of 28% into a pool after removing impurities and washing them with water, and completely immerse the stem strips in the above solution, and soak for 12 hours at room temperature. Strain the soaked stems through a strainer and fully return the filtrate to the pool. The filtered stalks are naturally air-dried at room temperature until the water content is 20%, then stored in a storage cabinet for 6 hours, and then enter the next step of production and processing procedures such as cutting the stalks and drying the shredded stalks.

[0017] Compared with the large-scale production of cut stems, the color of the prepared cut stems is closer to that of shredded ...

Embodiment 2

[0019] Repeat Example 1, with the following differences: 40L of red wine with an alcohol content of 8°, 12L of sorghum wine with an alcohol of 50° to 55°, and 60L of pure water are poured into a pool of 250L, and the poured The added solution was stirred evenly and left for 4h. The stems were soaked in the pool with the above solution for 24h.

[0020] Compared with the large-scale production cut stem samples, the prepared shredded stems are closer in color to shredded tobacco, but the flexibility is slightly worse than the cut stems prepared in Example 1. In terms of sensory quality, the woodiness is significantly reduced, and the smoke is slightly Fruity, the irritation is significantly reduced, the smoke is rich and delicate, and the aftertaste is sweet.

Embodiment 3

[0022] Repeat Example 1, with the following differences: 60L of red grape juice, 15L of sorghum wine with an alcohol content of 50° to 55°, and 40L of pure water are poured into a pool with a volume of 250L, and the poured solution is stirred Evenly, place for 6h. The stems were soaked in the pool with the above solution for 24h.

[0023] Compared with the samples of large-scale production cut stems, the prepared shredded stems have a darker color, and in terms of sensory quality, the woody miscellaneous gas is significantly reduced, the irritation is significantly reduced, the aroma of the smoke is rich, delicate and soft, and the aftertaste is sweet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com