Method of rapidly removing harmful substance in waste incineration fly ashes

A technology for waste incineration and harmful substances, which is applied in the field of rapid removal of harmful substances in waste incineration fly ash. It can solve the problems of polluting water and soil environment, increasing the volume of waste, and being unable to reuse fly ash, etc., and achieves the effect of short processing time and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

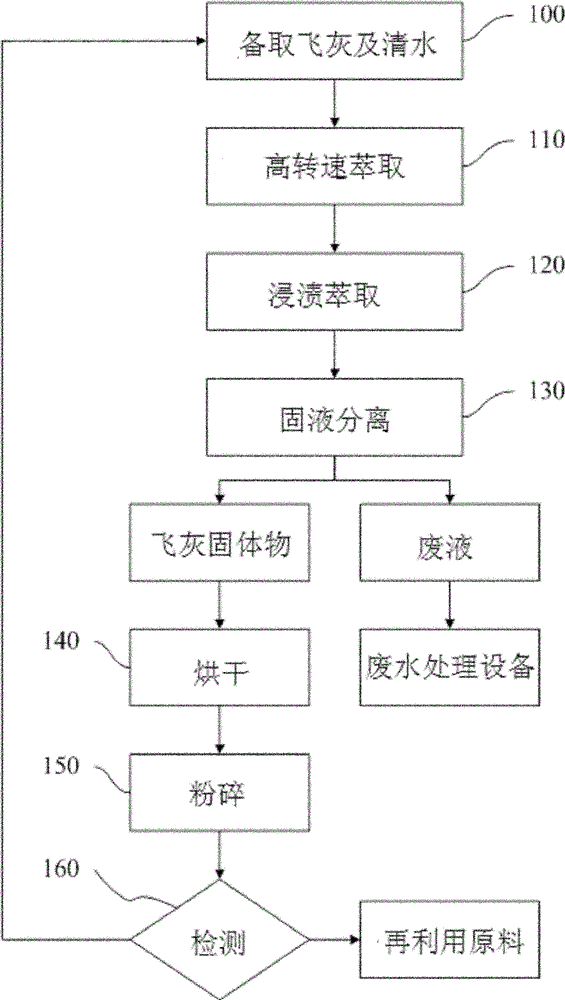

[0027] Hereinafter, a preferred embodiment of the present invention is cited and described in detail in conjunction with the accompanying drawings as follows, wherein:

[0028] see figure 1 As shown, the method for fast removal of waste incineration fly ash harmful substances in a preferred embodiment of the present invention mainly includes the following steps:

[0029] The first step of the present invention is to get fly ash and clear water 100: in terms of waste incineration plant, fly ash is the combined fly ash collected by the air pollution control equipment of the waste incineration plant, and the clean water can be tap water, distilled water, or Softened water.

[0030] The second step of the present invention is stirring and extracting 110: adding clean water into the fly ash, fully stirring the fly ash and clean water in a high-speed stirring manner, crushing the fly ash for extraction. The weight ratio of clean water to fly ash (dry weight) is 2-5:1, the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com