Novel process for removing light components in stock solution of furfural and special production apparatus

A technology for removing light and furfural, applied in distillation separation, organic chemistry, chemical instruments and methods, etc., can solve the problems of environmental pollution, failure, low crude aldehyde rate and refining rate, etc. Improve and reduce the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

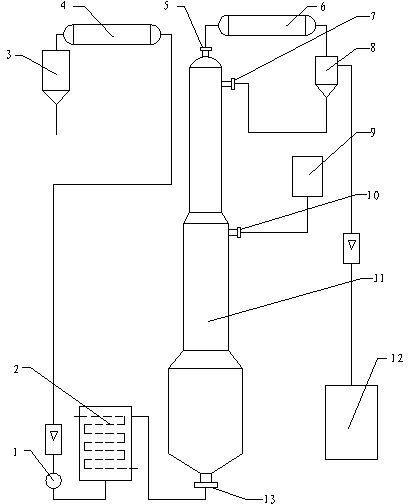

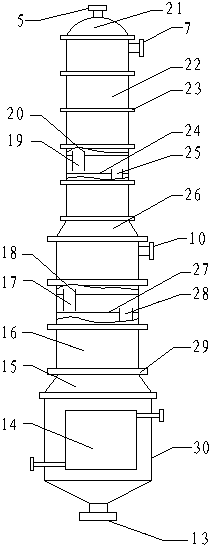

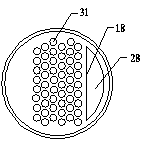

Method used

Image

Examples

Embodiment 1

[0018] ①Heating the tower kettle 30 of the special light removal tower 11, and heating the temperature of the tower kettle 30 to 100-102°C;

[0019] ② Feed the furfural stock solution into the special light removal tower 11 from the feed port 10 of the special light removal tower 11, the feed rate is 8 tons / hour, keep the temperature of the tower kettle 30 at 100-102°C, and the pressure of the tower kettle 30 0.1~0.15kg / cm 2 , the volume of the liquid in the tower still 30 is 2 / 3 of the volume of the tower still 30, and the temperature at the top of the tower is maintained at 70°C, and the light components, water and furfural mixed steam steamed from the distillation outlet 5 are cooled by the condenser 6 The formed condensed liquid enters the liquid separator 8, and part of the condensed liquid flows back into the special light removal tower 11 through the return port 7 from the bottom of the liquid separator 8. The pipeline on the liquid separator 8 side flows into the stor...

Embodiment 2

[0024]①Heating the tower kettle 30 of the special light removal tower 11, and heating the temperature of the tower kettle 30 to 102-105°C;

[0025] ② Feed the furfural stock solution into the special light removal tower 11 from the feed port 10 of the special light removal tower 11, the feed rate is 8-10 tons / hour, keep the temperature of the tower kettle 30 at 102-105 °C, the tower kettle 30 pressure 0.15~0.20kg / cm 2 , the volume of the liquid in the tower still 30 is 2 / 3 of the volume of the tower still 30, the temperature at the top of the tower is maintained at 65°C, and the light components, water and furfural mixed steam steamed from the distillation outlet 5 are cooled by the condenser 6 The formed condensed liquid enters the liquid separator 8, and part of the condensed liquid flows back into the special light removal tower 11 through the return port 7 from the bottom of the liquid separator 8. The pipeline on the side of the liquid separator 8 flows into the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com