Compatilizer and preparation method thereof, alloy comprising same and production method thereof

A technology of compatibilizer and alloy, which is applied in the field of plastic compatibilizer and its preparation, and can solve the problems that the impact strength of PPO/PP alloy cannot be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the above-mentioned compatibilizer, the components other than the peroxide initiator such as styrene ethylene butadiene block copolymer, polyphenylene ether, maleic anhydride monomer and processing aids are put into high-speed Mix in the mixer, and then feed into the twin-screw extruder through the main feed, add the peroxide initiator into the extruder through the side feed, and the temperature of each section of the extruder from the feed port to the head of the extruder The temperature is set between 80°C and 280°C, and the mixed material is melted and plasticized, kneaded and mixed, extruded through the head, drawn, cooled, pelletized, and dried to obtain the product.

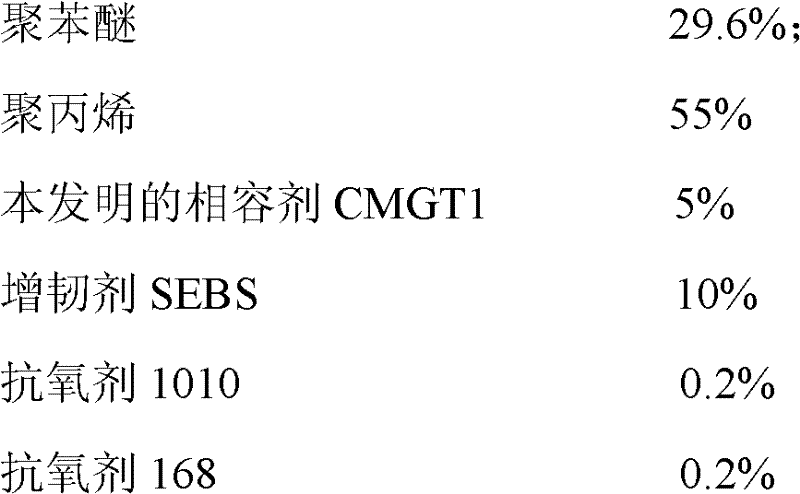

[0019] The present invention also provides a polyphenylene ether / polypropylene alloy, the polyphenylene ether / polypropylene alloy contains polyphenylene ether, polypropylene, a compatibilizer, a toughening agent, and an antioxidant, and the compatibilizer is based on Invente...

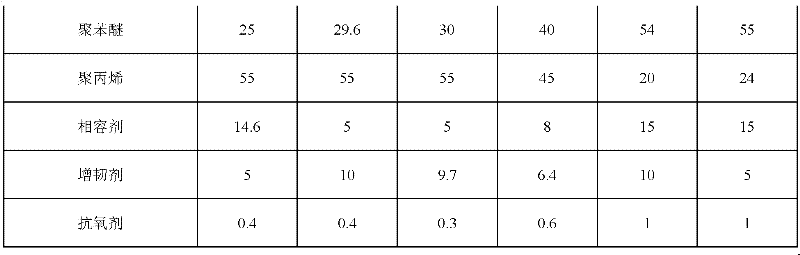

Embodiment 1~6

[0032] The present invention will be described in detail below in conjunction with specific embodiments.

Embodiment 1

[0034] One, prepare compatibilizer of the present invention:

[0035] Take the following components by weight percentage:

[0036] Styrene Butadiene Block Copolymer 60%;

[0037] PPO resin 35%;

[0038] Maleic anhydride monomer 4%;

[0039] Dicumyl peroxide 0.5%;

[0040] Silicone 0.5%;

[0041] Put the other components except the initiator into the high-speed mixer according to the proportion and mix them for 10 minutes, then add them into the twin-screw extruder after metering through the main feeder, and add the initiator into the extruder after metering through the side feeder , the screw temperature of each section of the extruder from the feed port to the head is set between 100°C and 240°C, and the mixed material is melted and plasticized, kneaded and mixed, extruded from the head, drawn, cooled, pelletized, Dry to obtain the compatibilizer product CMGT1.

[0042] 2. Preparation of polyphenylene ether / polypropylene alloy

[0043] Put the polyphenylene ether resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com