Device used for quenching shield machine hobbing cutter ring

A shield machine and cutter ring technology, which is applied in the field of cutter ring quenching devices, can solve the problems of reducing the thermal insulation performance of the device, reducing the effect, increasing the cooling speed of the inner layer of the roller ring, etc., and achieving the effect of reducing diffusion and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

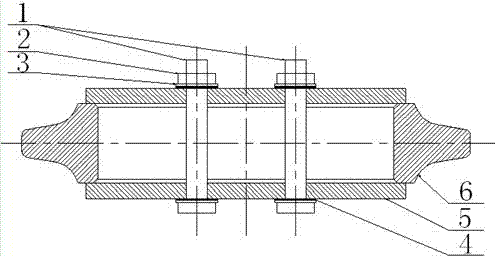

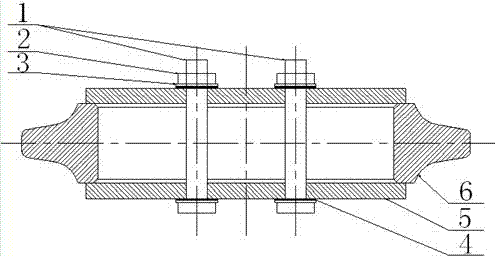

[0014] The knife ring is quenched after rough machining, and the knife ring is quenched according to the attached figure 1 The shown method protects the inner surface of the cutter ring 6 with an insulating asbestos board 5 . The heat insulating asbestos board 5 has a diameter of 300 mm and a thickness of 20 mm. The heat insulation asbestos board 5 has a diameter of The 16mm ceramic bolt 1, gasket 3 and nut 2 are fixed, the distance between the centerlines of the two ceramic bolts is 90mm, and a high temperature resistant sealing ring 4 is placed between the heat insulating asbestos board 5 and the gasket 3. The quenching process of the knife ring is to put the heat-insulating asbestos board 5, the ceramic bolt 1, the gasket 3, the nut 2 and the high-temperature sealing ring 4 together with the knife ring 6 into the heat treatment furnace for heating and heat preservation, and then quickly cool it with nitrogen. After quenching, the outer layer of the cutter ring 6 obtains ...

Embodiment 2

[0016] The knife ring is quenched after rough machining, and the knife ring is quenched according to the attached figure 1 The shown method protects the inner surface of the cutter ring 6 with an insulating asbestos board 5 . The heat insulating asbestos board 5 has a diameter of 310 mm and a thickness of 30 mm. The heat insulation asbestos board 5 has a diameter of The 20mm ceramic bolt 1, gasket 3 and nut 2 are fixed, the distance between the centerlines of the two ceramic bolts is 100mm, and a high temperature resistant sealing ring 4 is placed between the heat insulating asbestos board 5 and the gasket 3. The quenching process of the knife ring is to put the heat-insulating asbestos board 5, the ceramic bolt 1, the gasket 3, the nut 2 and the high-temperature sealing ring 4 together with the knife ring 6 into the heat treatment furnace for heating and heat preservation, and then quickly cool it with nitrogen. After quenching, the outer layer of the cutter ring 6 obtains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com