Zinc liquid cleanser

A purification agent and zinc liquid technology, which is applied in coating, metal material coating process, hot-dip plating process, etc., can solve the problems of increasing workload and production cost, plating particles, wrinkled skin and coating, and zinc liquid containing iron It can reduce the grinding workload, improve the performance and quality, and reduce the content of iron ions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

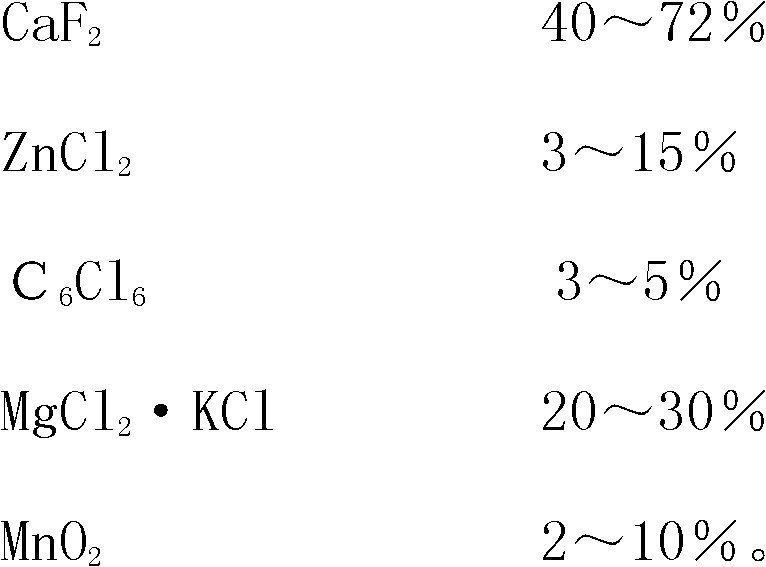

[0011] Embodiment 1: get CaF by weight 2 : 55%, ZnCl 2 : 10%, C 6 Cl 6 : 4%, MgCl 2 KCl: 25%, MnO 2 : 6%.

Embodiment 2

[0012] Embodiment 2: get CaF by weight 2 : 48%, ZnCl 2 : 15%, C 6 Cl 6 : 5%, MgCl 2 KCl: 30%, MnO 2 :2%.

[0013] Heat and melt KCl and MgCl in a pot 2 Broken while hot to get MgCl 2 KCl powder, respectively by embodiment 1 and embodiment 2 parts by weight, MgCl 2 ·KCl powder and ZnCl 2 、C 6 Cl 6 , CaF 2 , MnO 2 Mix evenly, and press at room temperature to form a bulk zinc liquid purifier.

[0014] Liquid zinc clarifier of the present invention is used like this:

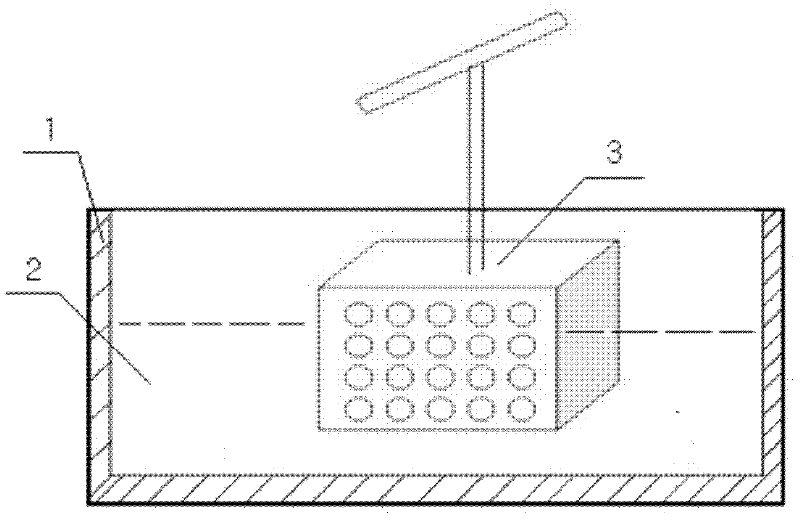

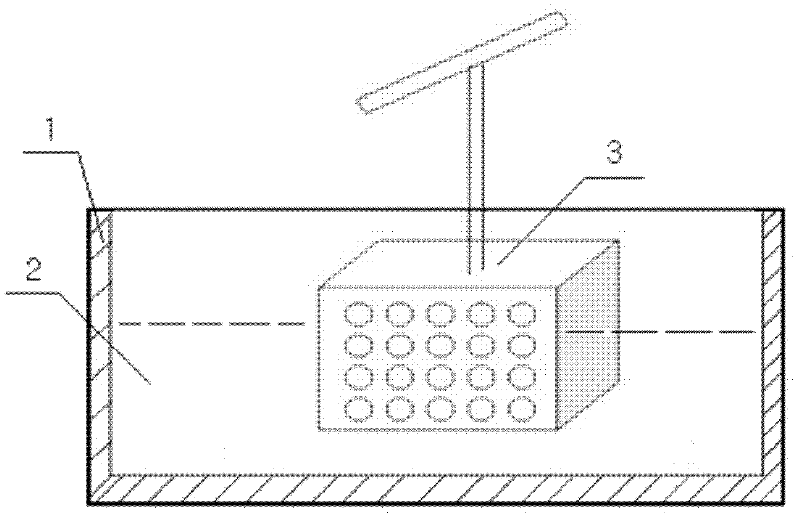

[0015] According to the size of the zinc pot 1, a self-made porous purification box 3 with locking activities; get 0.04% to 0.06% of the zinc liquid purifying agent of the zinc liquid amount (such as: 5 tons of zinc liquid plus 2-3 kg of zinc liquid purifying agent) ; be placed in the porous purification box 3; the porous purification box 3 is inserted into the zinc liquid of 1 / 3~2 / 3 depth, the porous purification box 3 moves back and forth along the length direction of the zinc pot, until the zinc liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com