Nano material modified or functionalized silk protein-based material and preparation method thereof

A technology of nano-materials and silk proteins, which is applied in textiles and papermaking, fiber treatment, animal fibers, etc., can solve the problems of undisclosed silk fibers or silk fabric modification occurring in silk fibers, etc., and achieve the effect of cooling fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

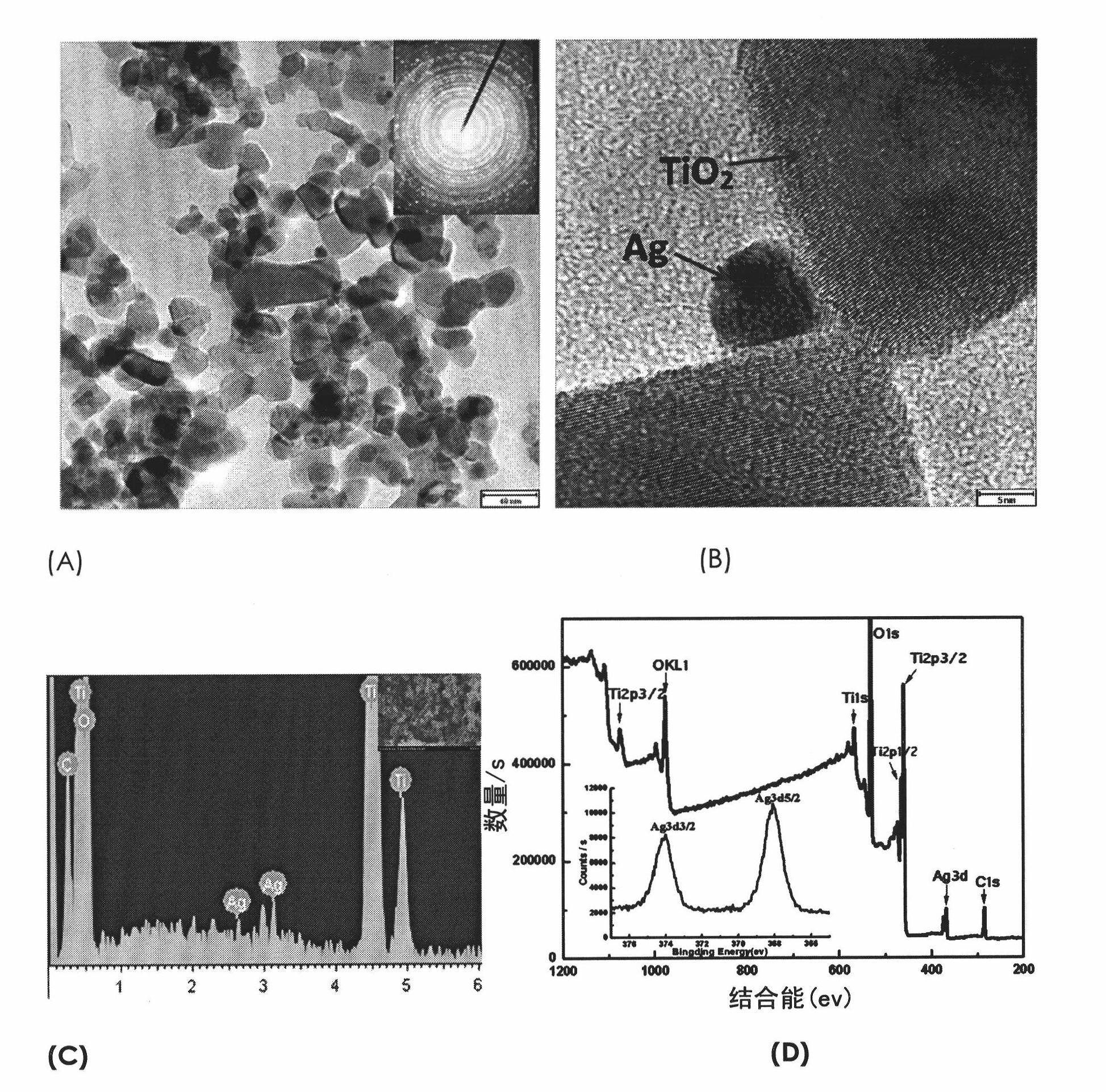

[0158] Example 1 Synthesis of TiO by Photocatalytic Reduction 2 Ag nanomaterials

[0159] Will contain 0.1g TiO 2 (P25) 50ml 0.1MAgNO 3 The ethanol solution was irradiated with a 20W ultraviolet lamp under magnetic stirring. The irradiation distance (distance from the lamp to the liquid surface) was 10 cm, and the irradiation time was 2 minutes. Then due to Ag + reduced to Ag 0, the color of the suspension changed from white to brown. The product was collected and washed with deionized water. Finally, it was completely dried at 40 °C.

Embodiment 2

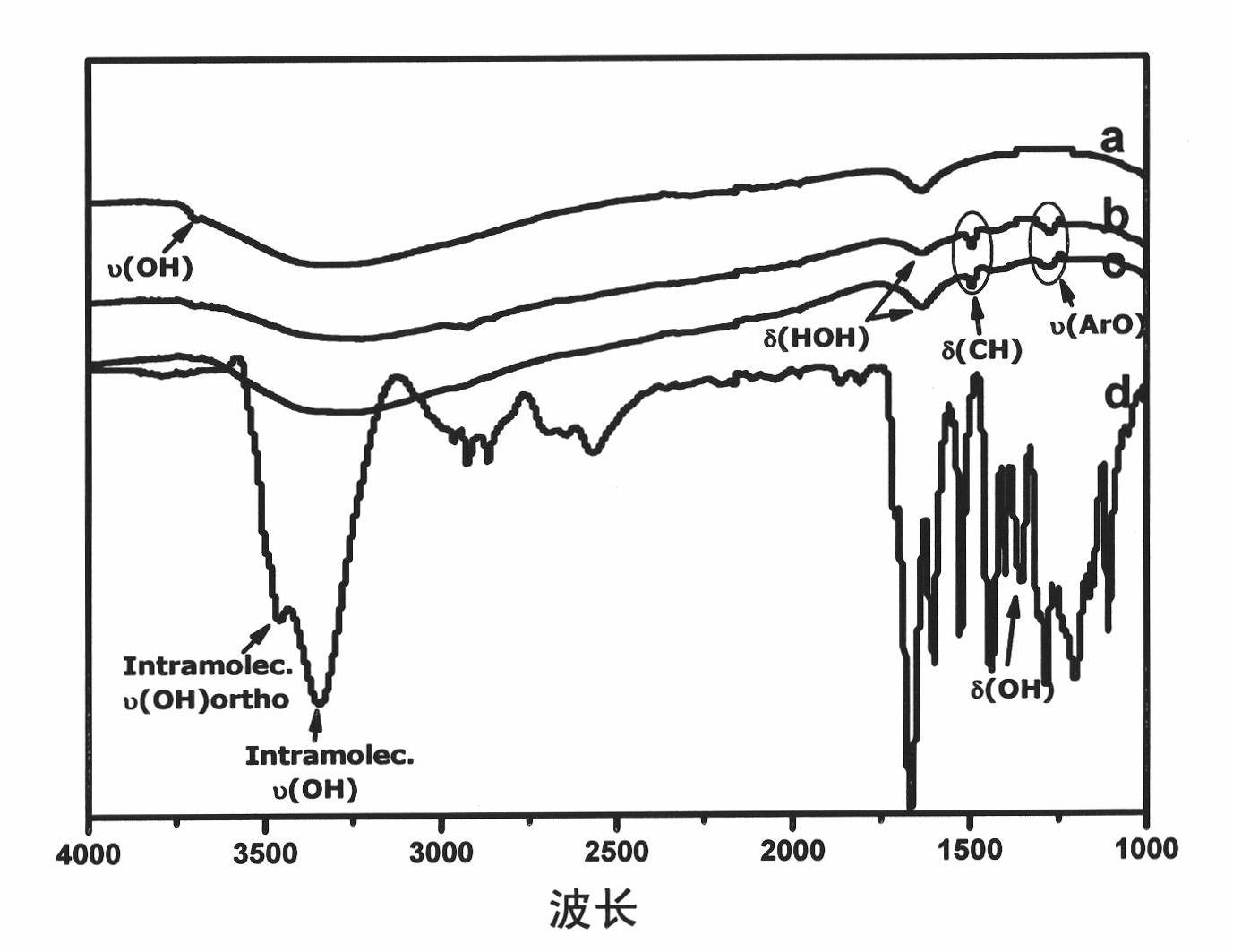

[0160] Example 2 Using DHBPA to modify TiO 2 Ag nanomaterials

[0161] A total of 1.00 g of TiO 2 (P25), TiO 2 The Ag nanomaterials were respectively dispersed into 100ml of an aqueous solution containing 10mg of DHBPA. The mixture was magnetically stirred at room temperature for 10 minutes, and then centrifuged at 8000 rpm for 10 minutes. The solid product was washed thoroughly with deionized water and dried at 40 °C.

Embodiment 3

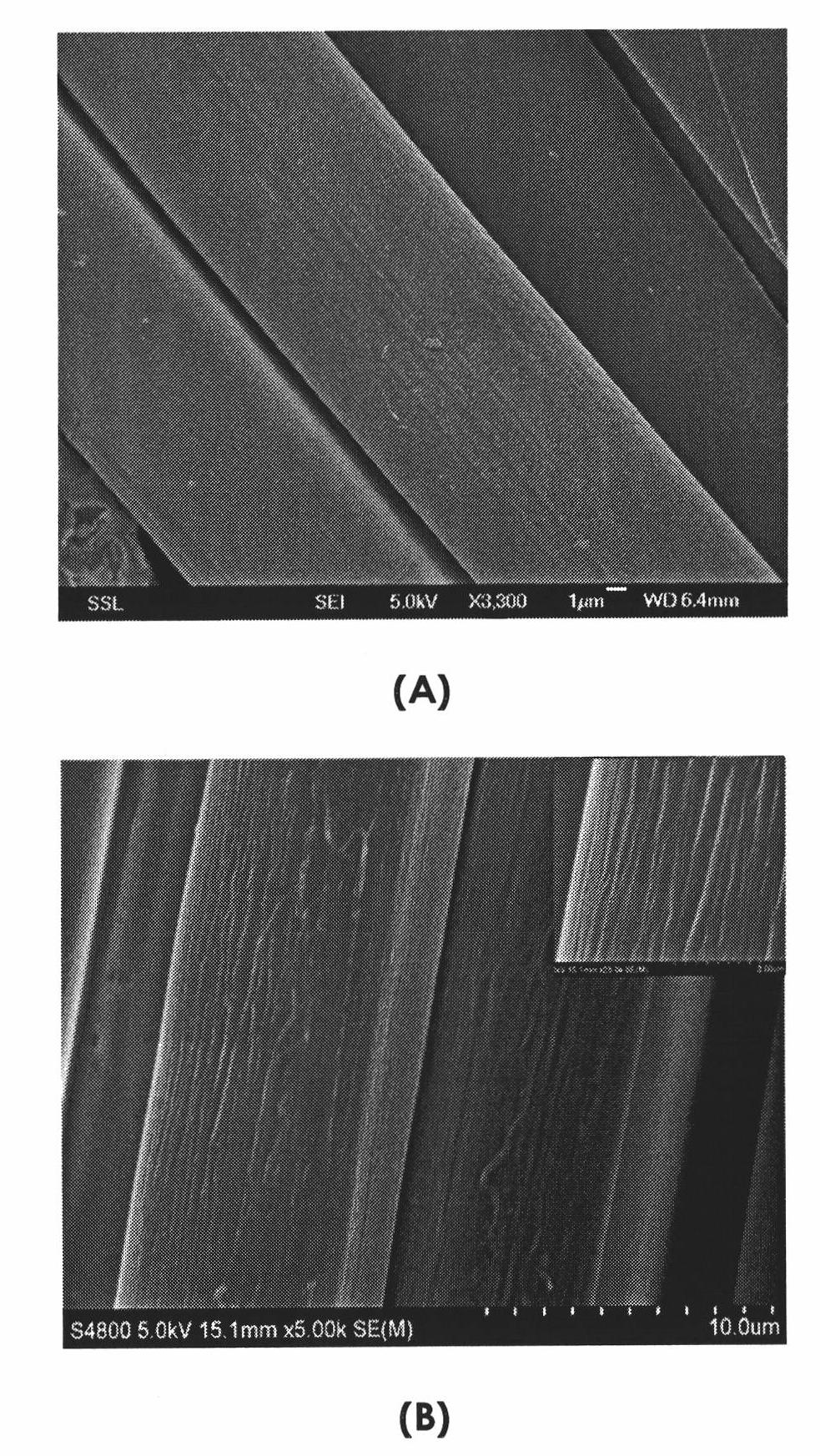

[0162] Example 3 SFF samples were processed in the following two steps:

[0163] (1) Immerse the SFF sample in 100ml chitosan aqueous solution (containing 0.5g chitosan, 8g BTCA, 3g SHP) at 25°C, and then pad at 90% liquid absorption. Next, the samples were dried at 80°C for 5 minutes and baked in a laboratory oven at 160°C for 3 minutes.

[0164] (2) Chitosan-treated SFF samples, 0.1g DHPBA-modified nanomaterials (respectively TiO 2 and TiO 2 Ag) was placed in 40 ml of deionized water and gently mechanically stirred for 10 minutes. Then extract the SFF sample and at 15kg / cm 2 Padding under pressure. Then, the samples were cured in a laboratory oven at 80 °C for 5 min and washed with deionized water followed by ultrasonic treatment for 5 min to remove unfixed material. Finally, the samples were dried at room temperature.

[0165] characterize

[0166] The morphologies of the nanomaterials and SFF samples obtained in Examples 1-3 were characterized by a transmission elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com