Preparation method of graphene/nanofiber hybrid gel membrane with photo-thermal conversion function

A nanofiber, hybrid gel technology, applied in the field of graphene/nanofiber hybrid gel film preparation, can solve the problems of low evaporation speed and photothermal conversion efficiency, achieve good photothermal conversion efficiency, improve water Evaporation speed and the effect of improving photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

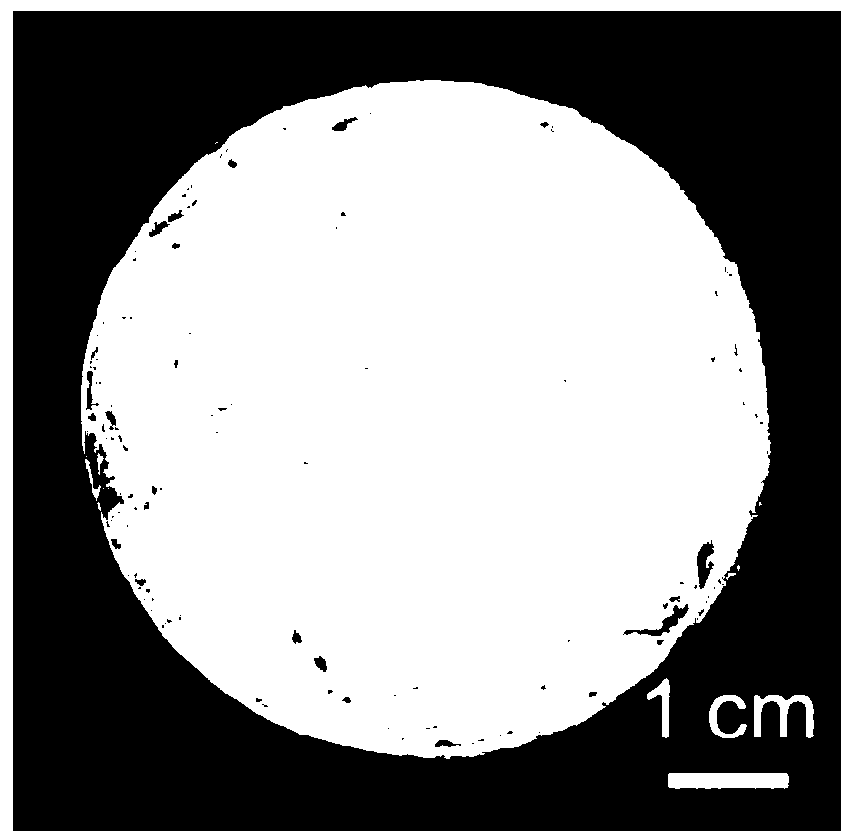

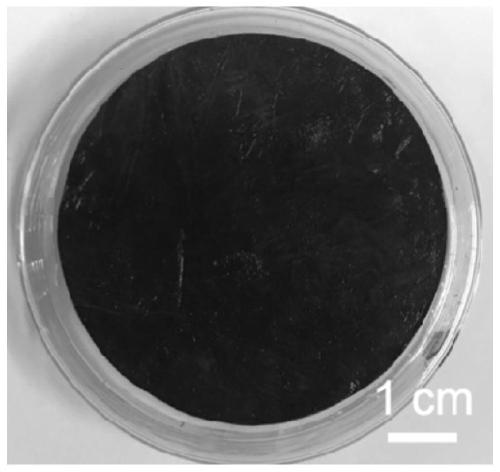

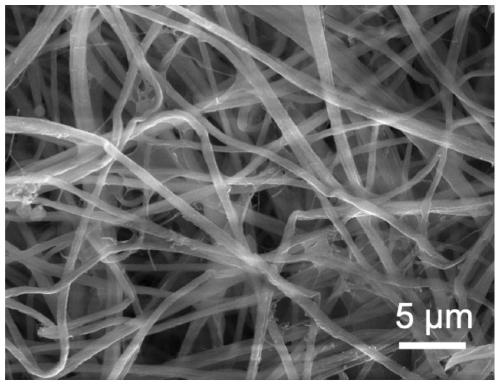

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the preparation method of a kind of graphene / nanofiber hybrid gel film with photothermal conversion function in this embodiment is carried out according to the following steps:

[0028] One, the preparation of gel fiber:

[0029] Under the conditions of temperature 80℃~90℃ and stirring speed 100rpm~300rpm, dissolve cellulose acetate and polymethacrylic acid in N,N-dimethylformamide, stir for 48h~72h to obtain spinning solution , under the conditions of a high-voltage electric field of 15kV-17kV, a spinning distance of 20cm-30cm, and a syringe pump advancing speed of 1mL / h-2mL / h, the spinning solution is spun by a single-axis electrospinning device, and the spinning The time is 8h to 24h, and then the gel fiber is obtained by using the flat-plate collecting method;

[0030] The quality of the cellulose acetate and the volume of N,N-dimethylformamide are (0.5~1)g:8.5mL; the quality of the polymethacrylic acid and the volume of N,N-dimethylformami...

specific Embodiment approach 2

[0041] Specific embodiment two: the difference between this embodiment and specific embodiment two is: the mixed acid solution described in step two is a mixture of phosphoric acid and concentrated sulfuric acid; the volume ratio of described phosphoric acid and concentrated sulfuric acid is 1: (7~9) ; The mass percentage of the phosphoric acid is ≥ 85%; the mass percentage of the concentrated sulfuric acid is 95% to 98%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, under the condition that the temperature is 80°C-85°C and the stirring speed is 100rpm-200rpm, cellulose acetate and polymethacrylic acid are mixed Dissolve in N,N-dimethylformamide, stir for 48h-60h to obtain spinning solution. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com