Handheld four-travel engine lubrication system

A four-stroke engine and lubricating system technology, applied in the field of lubricating systems, can solve the problems of poor working reliability, uneven pressure distribution, cumbersome assembly, etc., and achieve the effects of less lubricating oil loss, smooth breathing and ventilation, and stable and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

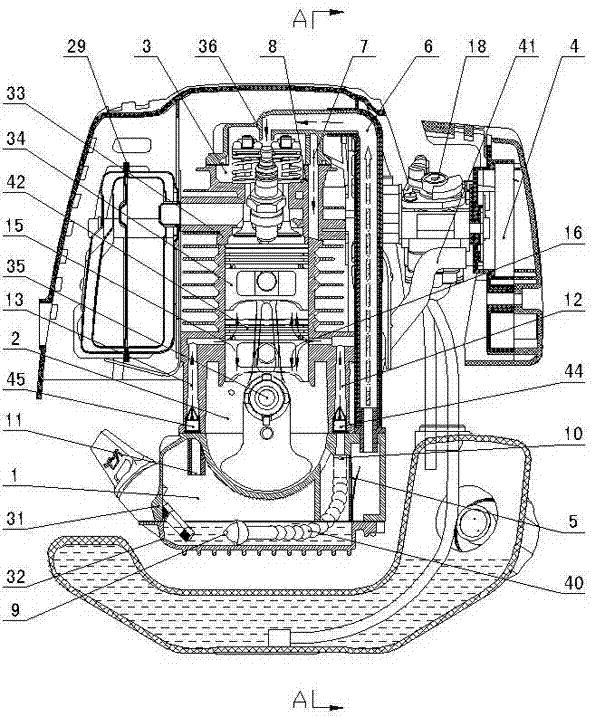

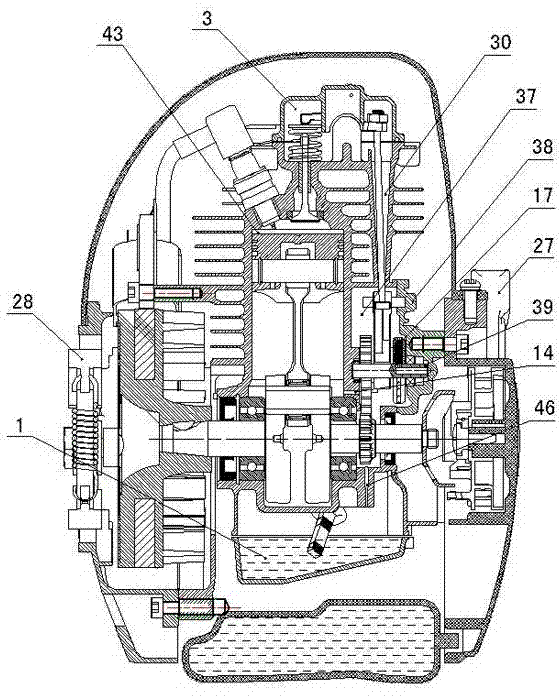

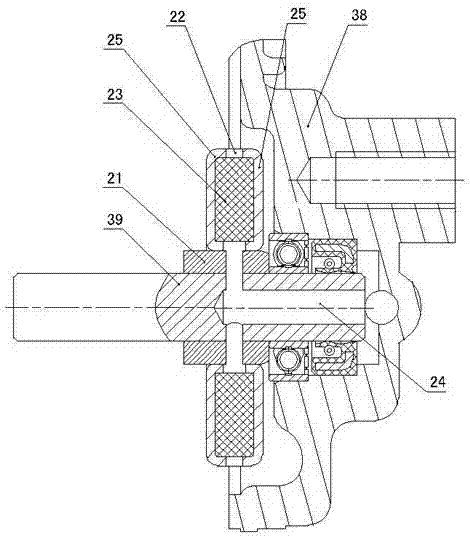

[0025] Figure 1 to Figure 6 As shown, the present invention creates a specific embodiment of a hand-held four-stroke engine lubrication system, which includes the oil storage chamber 1 formed by the bottom case 32 and the lower case 31, the crank chamber formed by the lower case 31 and the upper case 33 2. The valve chamber 3 formed by the upper case body 33 and the cylinder head cover 36, the cam chamber 37 formed by the upper case body 33 and the cam chamber cover 38, the tappet chamber 30 connecting the valve chamber 3 and the cam chamber 37, and the crank chamber A crankshaft connecting rod assembly 32 and a piston 34 are installed in the 2, and the carburetor 18 is connected to the oil tank. The upper and lower boxes 33, 31 are correspondingly provided with first and second inlets connecting the oil storage chamber 1 and the crank chamber 2. Oil passages 12, 13, the first and second oil inlet passages 12, 13 are provided with first and second one-way valves 44, 45 corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com