Electromagnetic induction heat exchanger

An electromagnetic induction and heat exchanger technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low heat exchange efficiency, waste of energy, waste of electric energy, etc., to increase the contact area, improve the The effect of heating speed and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

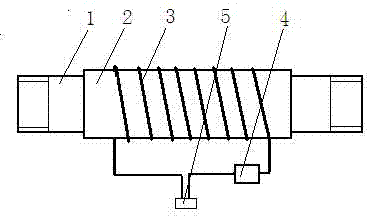

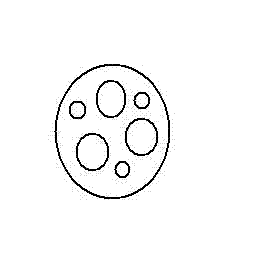

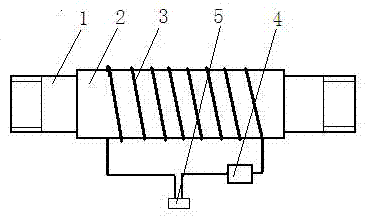

[0012] As shown in the drawings, an electromagnetic induction heat exchanger is provided with a columnar heating element 1, and the two ends of the heating element 1 are respectively provided with connecting threads connected with the water outlet pipe of the water inlet pipe. There are at least three threads in the heating element 1 Through the water conduction channel, the heating element 1 is provided with an insulating layer 2, and an induction coil 3 is wound on the insulating layer 2. The induction coil 3 is wound on the insulating layer 2 in a spiral shape, and the induction coil 3 is connected to the power connector 5 through the controller 4. Connected, the insulating material is surrounded by an electromagnetic induction coil, and the coil is passed through a high-frequency, high-voltage pulse current, and the heating element (magnetic cylinder) generates an eddy c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com