Solar terminal box

A junction box and solar energy technology, applied in the field of solar photovoltaics, can solve the problems of increased junction box cost, limited heat dissipation effect, waste of sealant, etc., achieve good waterproof and dustproof effects, simple and time-saving installation, and prevent thermal expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

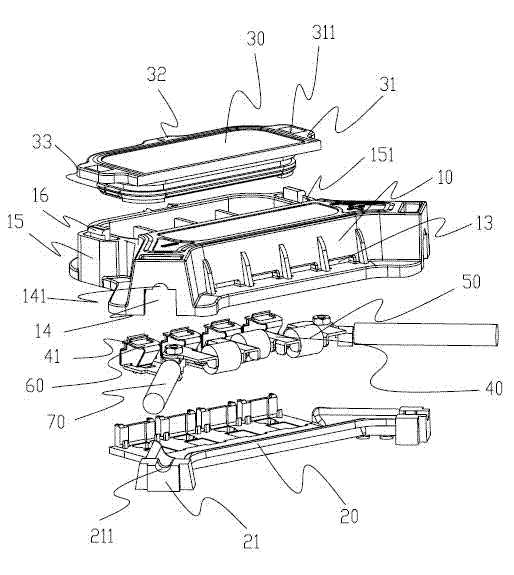

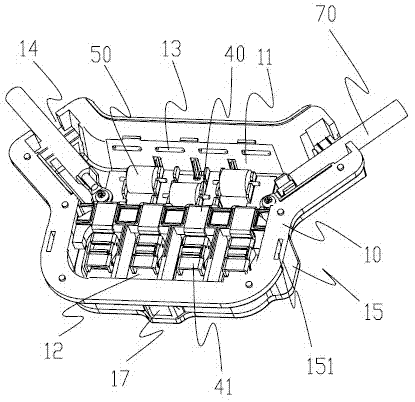

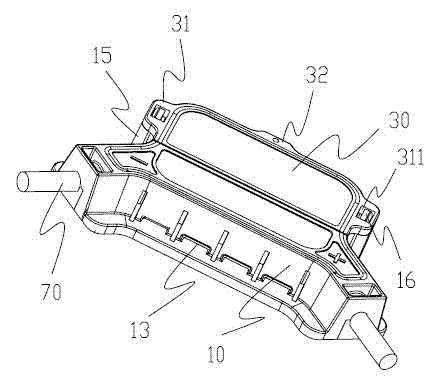

[0025] As shown in the accompanying drawings, the present invention includes a box body 10 , a bottom cover 20 matching the bottom of the box body 10 , and a surface cover 30 fastened to the top of the box body 10 . The bottom cover 20 is fixed to the box body 10 by ultrasonic welding. Both the edge of the bottom of the box body 10 and the middle of the bottom of the bottom cover 20 are provided with a fixing part, and the junction box is fixedly connected to the solar substrate through a sealant. The fixing part is in the shape of a "day", so that the connection between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com