Variable speed wheel-disc integrated mid-motor in electrical bicycle

A technology of electric bicycles and mid-mounted motors, which is applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of many metal consumables, limited battery energy, and reduced efficiency, and achieve complete force transmission, strong climbing ability, The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

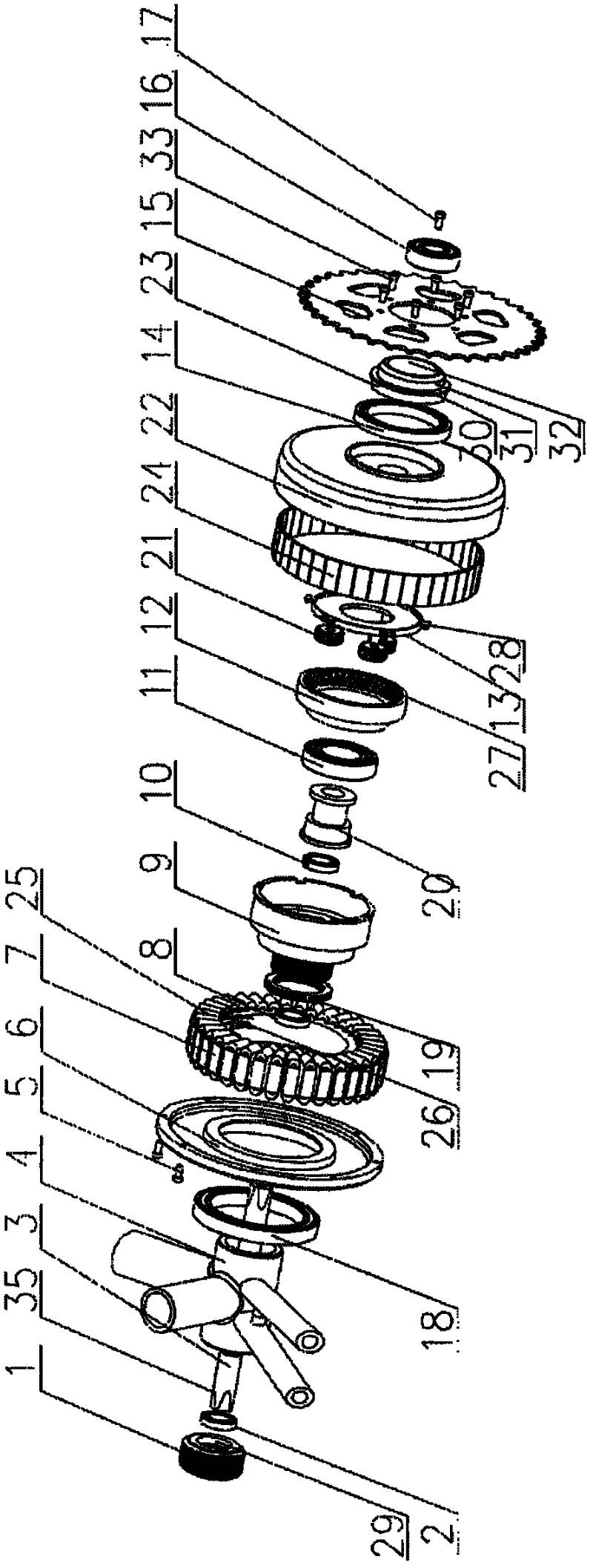

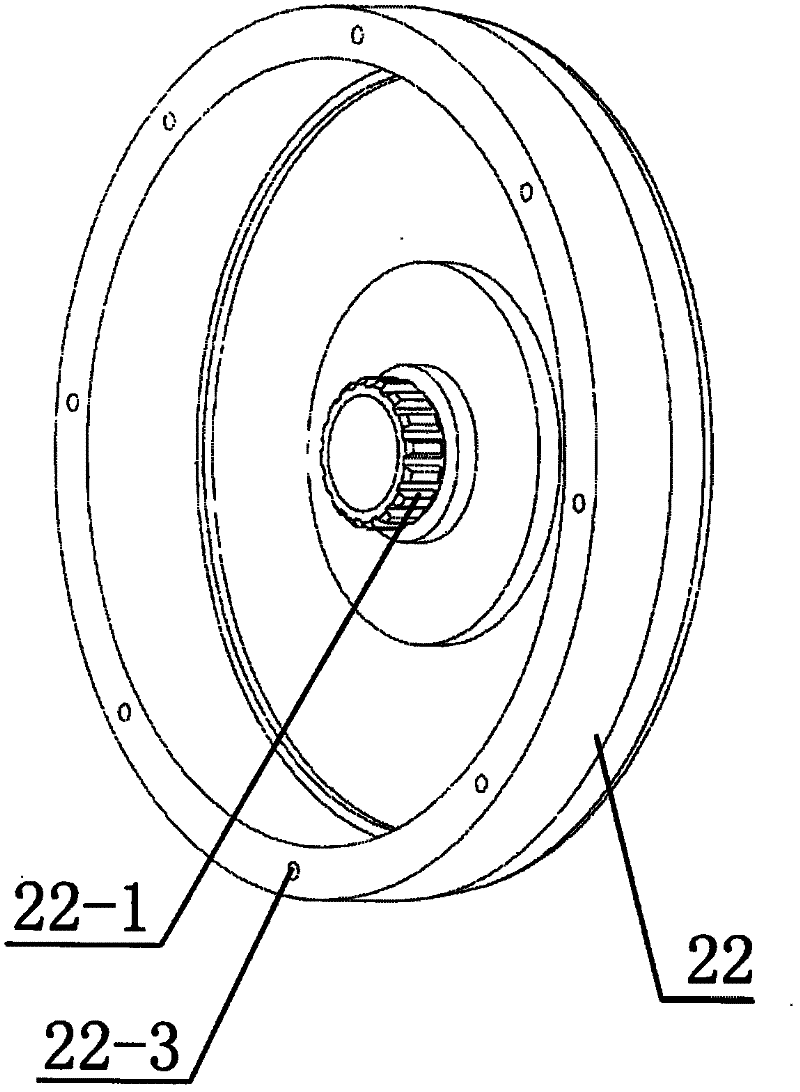

[0029] Refer to attached Figure 1-8, The electric bicycle motor wheel integrated central motor includes a left wire bowl 1, a bearing 2, a motor center shaft 3, a screw 5, an inner end cover of the motor 6, a stator silicon steel sheet (stator punching sheet) 7, a bearing 2 8, Stator inner core 9, bearing three 10, one-way clutch one 11, internal gear 12, planet carrier 13, bearing four 14, sprocket (chainring) 15, one-way clutch two 16, screw two 17, bearing five 18, right Lock nut 19, internal gear shaft 20, planetary gear 21, motor outer end cover 22, magnetic steel 24 and sprocket fixing ring 23.

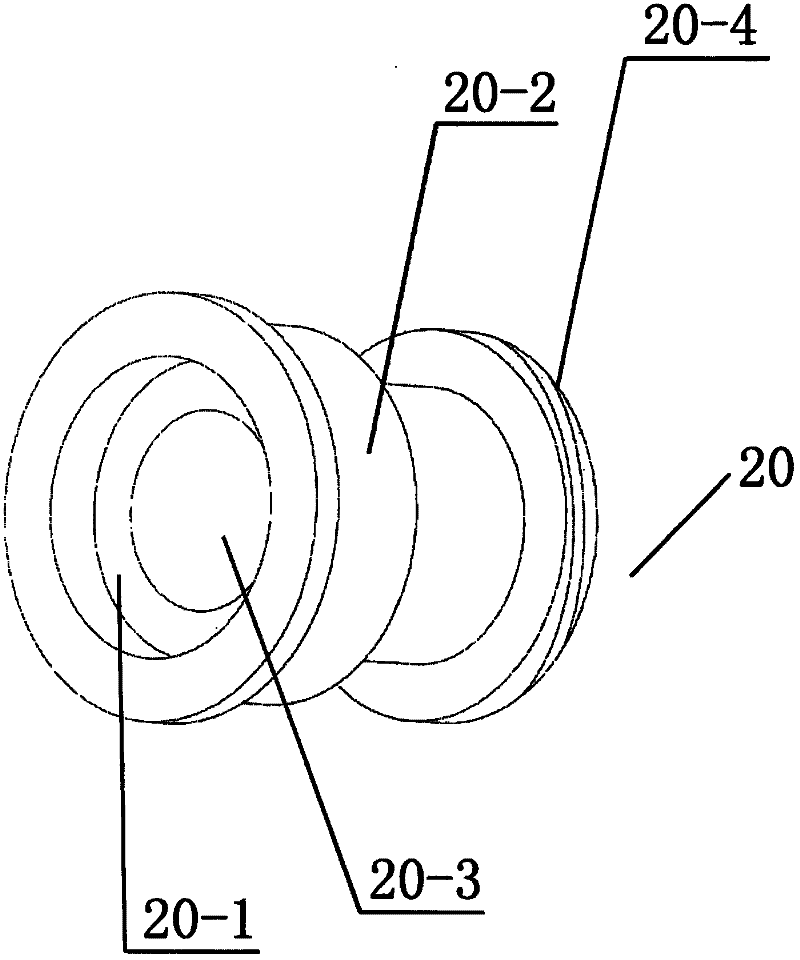

[0030] The left end of the internal gear shaft 20 is provided with three bearing mounting holes 20-1, the right end of the internal gear shaft 20 is provided with a fixed thread 20-4, a clutch installation step 20-2, and the internal gear shaft 20 is provided with a through hole 20-3 for installation The middle shaft 3 of the motor, the bearing three 10 are installed in the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com