Automatic-welding special repairing machine for train coupler knuckle

An automatic welding and train technology, applied in welding equipment, welding accessories, arc welding equipment, etc., to achieve the effect of smooth appearance, simple operation and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

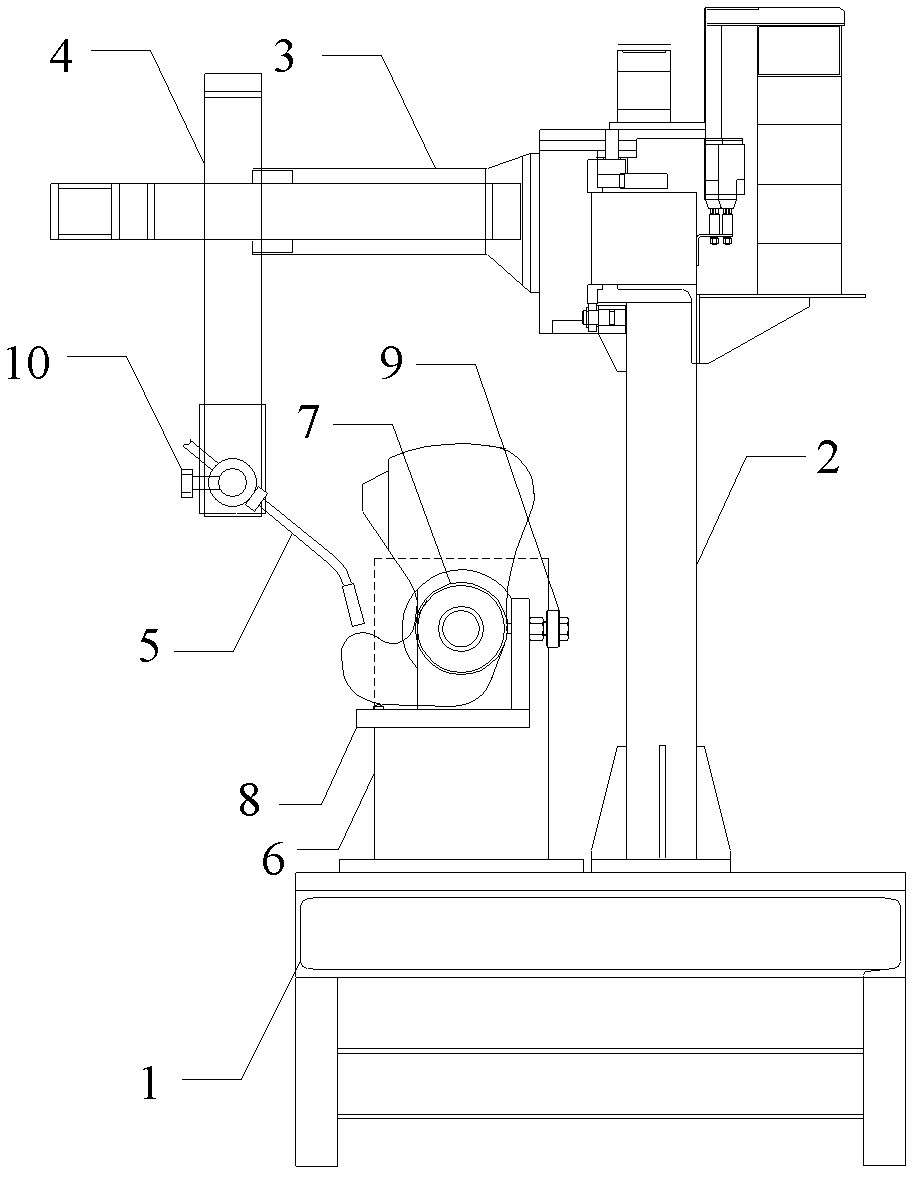

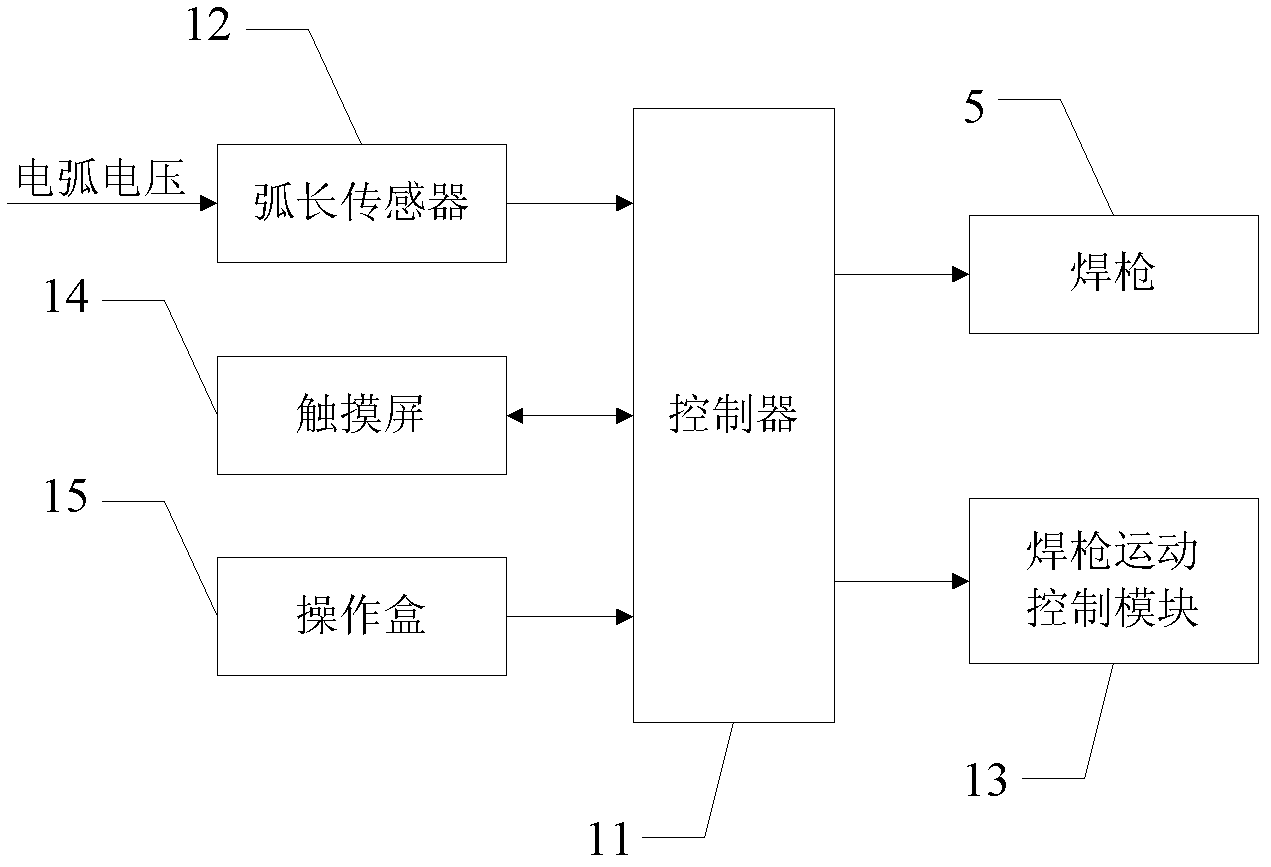

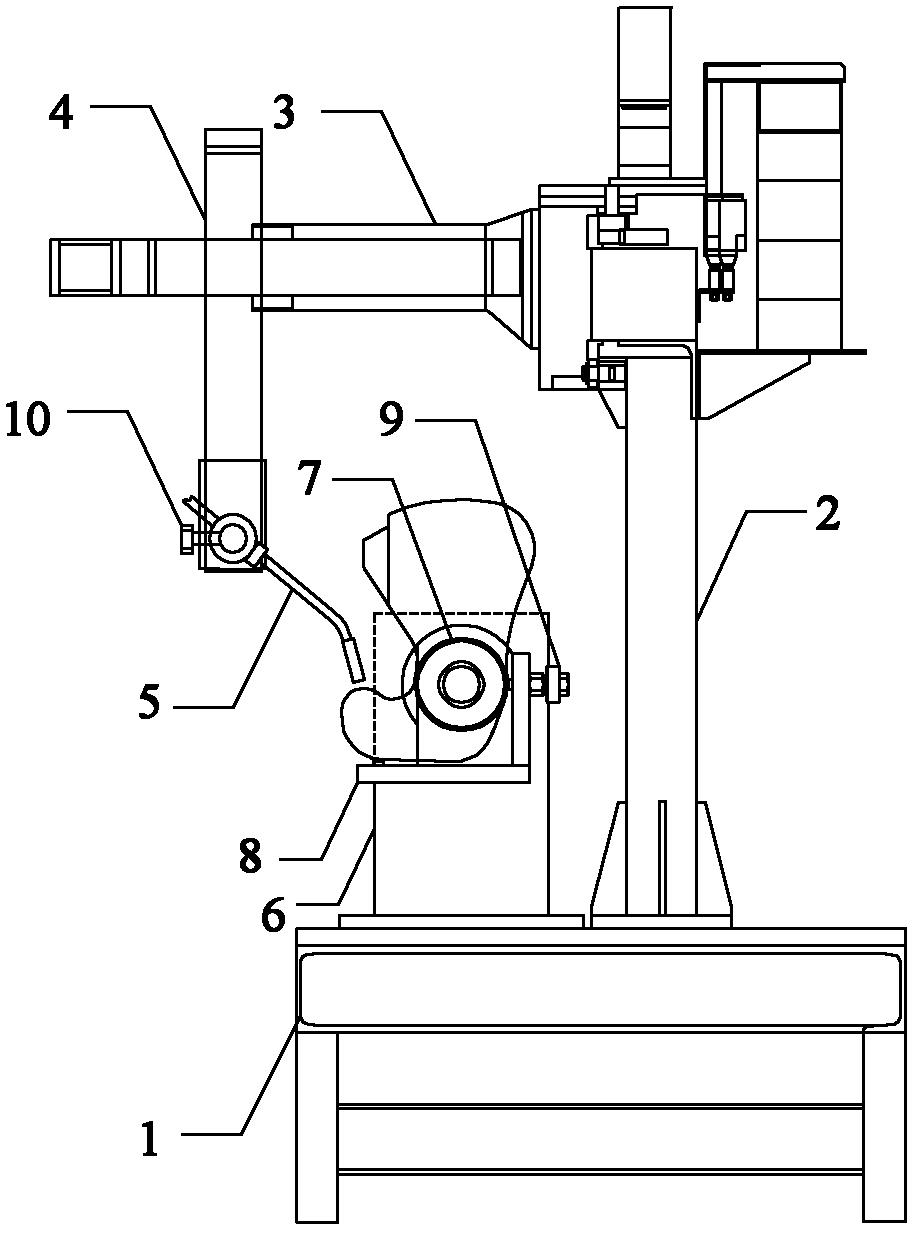

[0014] Specific implementation mode 1. Combination figure 1 Description of this embodiment, the train knuckle automatic welding repair machine, which consists of a base 1, a column 2, a beam 3, a cross carriage 4, a welding torch 5, a base 6, a rotating shaft 7, an "L" shaped bent plate 8, and a top wire Composed of rod 9, angle adjustment mechanism 10, controller 11 and arc length sensor 12, welding torch motion control unit 13 includes column 2, beam 3, cross carriage 4 and angle adjustment mechanism 10, column 2 is fixed on the base 1, beam 3 Installed on the column 2, the cross carriage 4 is installed on the crossbeam 3, the welding torch 5 is installed on the cross carriage 4 through the angle adjustment mechanism 10 to realize up and down, left and right and front and rear movements, the base 6 is fixed on the base 1, and the rotating shaft 7 is installed on the side surface of the base 6, one panel of the "L" shaped bent plate 8 is fixed on the upper surface of the base...

specific Embodiment approach 2

[0019] Specific embodiment two, combine figure 2 This embodiment is described. The difference between this embodiment and the first embodiment is that it also includes a touch screen 14 , and the signal input and output ends of the touch screen 14 are connected to the signal input and output ends of the controller 11 .

[0020] In this embodiment, the touch screen 7 has a display function of current, voltage, speed, and system operation status, and can also perform welding bead programming.

specific Embodiment approach 3

[0021] Specific implementation mode three, combination figure 2 This embodiment is described. The difference between this embodiment and the second embodiment is that it also includes an operation box 15 , and the control signal output end of the operation box 15 is connected to the control signal input end of the controller 11 .

[0022] In this embodiment, the operation box 15 is composed of a plurality of control buttons for the operator to manually control the welding operation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com