Automatic paper feeding digital indentation paper folding machine

An automatic paper feeding and folding machine technology, applied in the field of creasing and folding machines, can solve the problems of poor folding accuracy, low degree of automation, low efficiency, etc., to improve the continuity of production, enhance the flexibility of use, enhance the The effect of scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

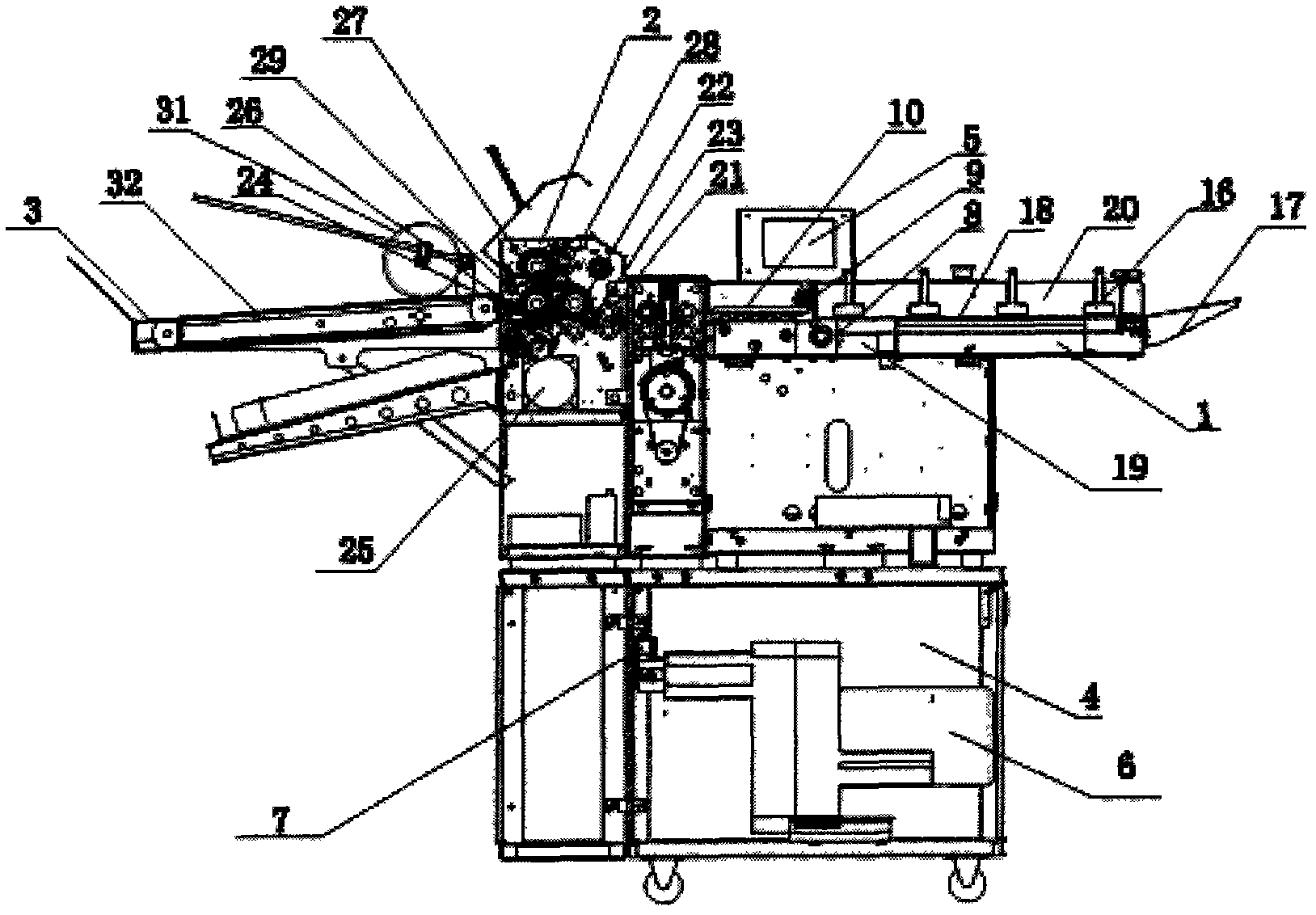

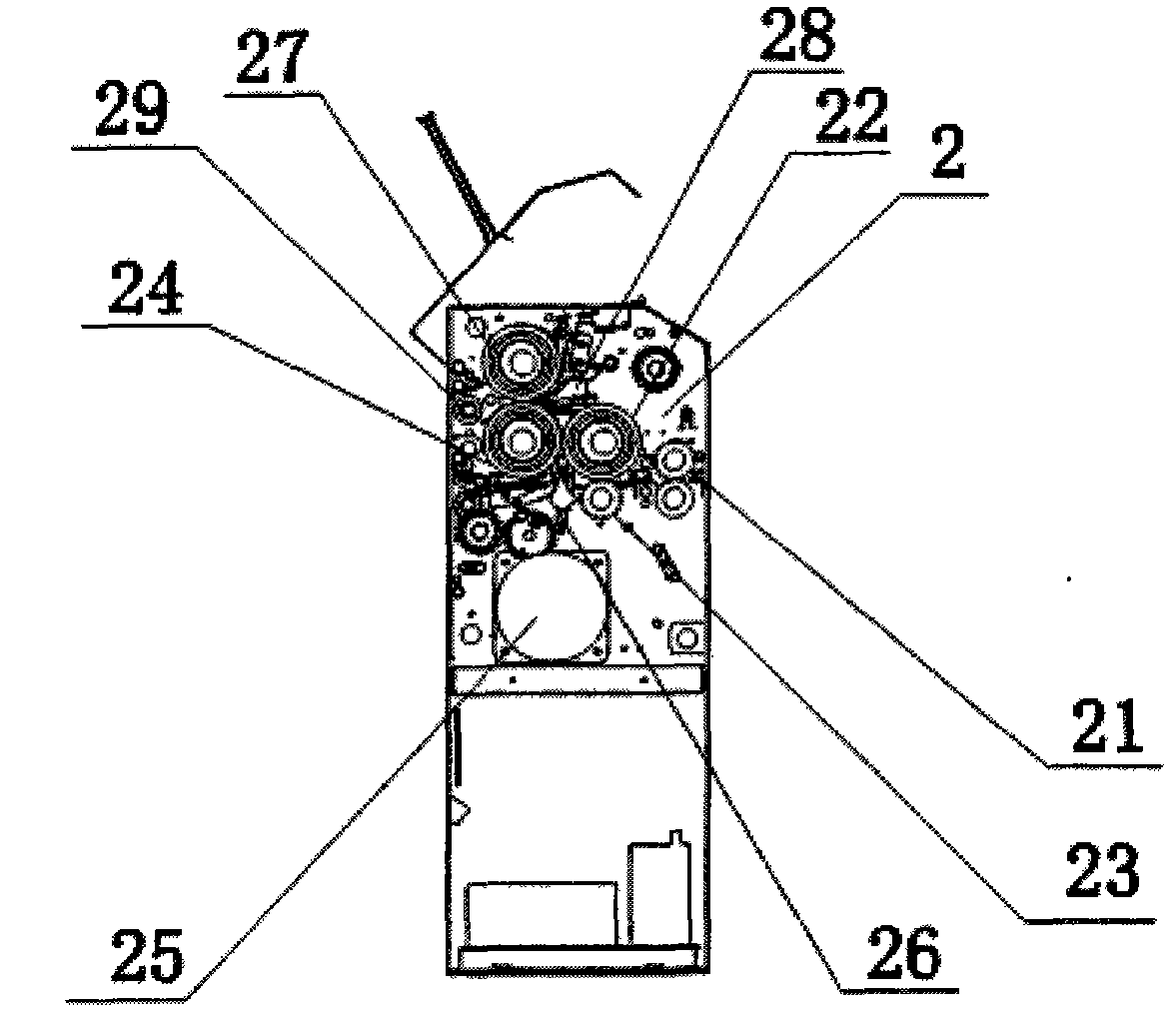

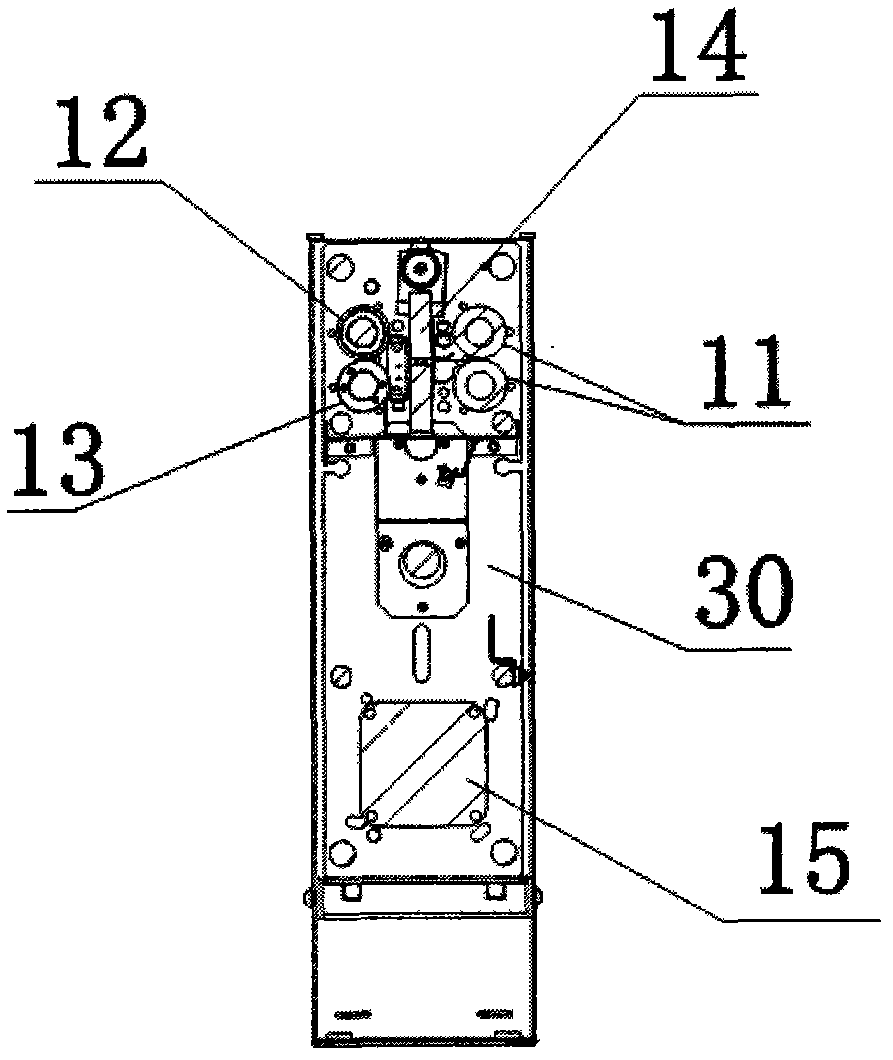

[0047] Embodiment one: if figure 1 , figure 2 , image 3 As shown, the paper feeding unit 1, the creasing unit 30, the folding unit 2 and the paper delivery unit 3 are an overall control structure of modular design or a serial structure controlled independently of each other, and each module can be freely selected according to requirements during work. Modules can be combined or selected independently, and can also be combined as a whole.

[0048] The paper feeding unit 1 mainly includes a suction wheel 8, a paper separation gauge mechanism 9, a deviation correction channel 10, a windshield slide plate 16, a paper feeding table extension board 17, a paper feeding table panel 18, a paper feeding drive motor 19, and a paper feeding table side plate 20. When the paper is stacked on the paper feeding table panel 18, the negative pressure blowing provided by the fan unit 4 will be delivered to the four air outlet holes of the paper feeding table side plate 20, and the air output...

Embodiment 2

[0053] Embodiment two: if Figure 4 , Figure 5 as shown, Figure 4 It is a positive indentation device, the upper part of the indentation tool 14 is an indentation concave knife mold 141, and the lower part is an indentation convex knife mold 142, Figure 5 It is a reverse indentation device, the upper part of the indentation tool 14 is an indentation convex knife die 142, and the lower part is an indentation concave knife die 141.

Embodiment 3

[0054] Embodiment three: as Figure 6 As shown, the main control board controls the interface board and driver board of the folding unit, the 72V power board provides power for the paper feeding motor, the 24V power board provides power for the knife insertion motor and the knife insertion electromagnet, and the 5V power board supplies the interface board of the folding unit , The drive board provides power, the knife insertion position sensor, paper feed detection sensor, paper output detection sensor, and paper feed motor are driven by the main control board to control the folding unit interface board and the drive board, and the power is turned on / off through the safety switch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com