Production process for reagent grade high-purity sulfuric acid

A sulfuric acid production, reagent-grade technology, applied in the field of reagent-grade high-purity sulfuric acid production technology, can solve the problems of sulfuric acid production and quality stability, to achieve the effect of ensuring stability and adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

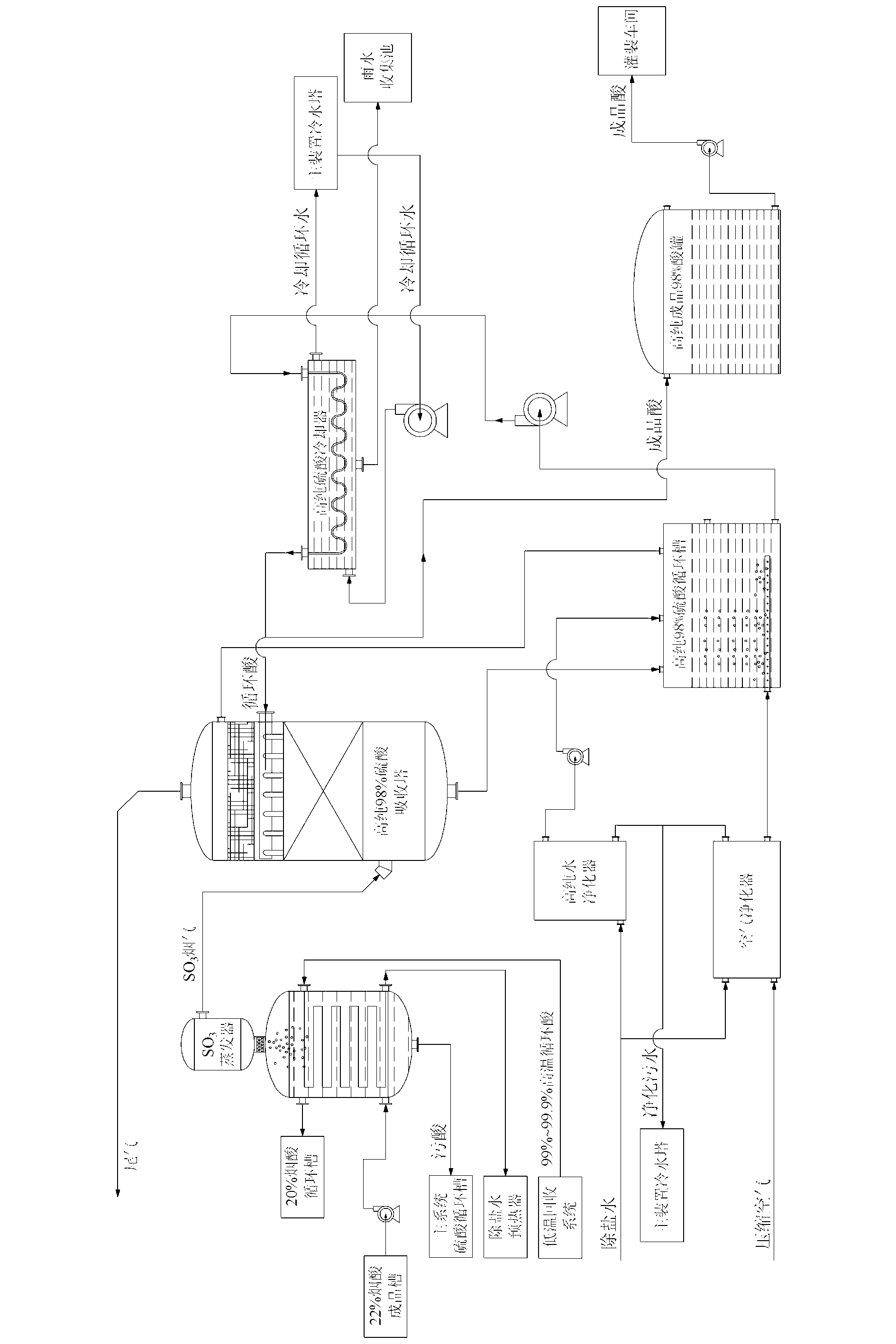

[0009] According to the accompanying drawings, the reagent grade high-purity sulfuric acid production process of the present invention includes a low-temperature waste heat recovery system and a 20% oleum production system in the production of sulfuric acid, including the following devices: SO 3 Evaporator, high-purity 98% sulfuric acid absorption tower, high-purity 98% sulfuric acid circulation tank, high-purity sulfuric acid cooler, high-purity water purifier, air purifier, high-purity finished 98% acid tank. Magnetic high-purity water pumps, magnetic sulfuric acid pumps, 20% niacin pump equipment, various pipelines and corresponding valves and instruments are also used.

[0010] Process flow of the present invention is as follows:

[0011] 20%~22% oleum is drawn from the 20% oleum circulation tank or the finished product 20% oleum tank to inject SO 3 Evaporator, under the heating of high-temperature concentrated sulfuric acid at 185°C to 200°C, evaporates high-concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com