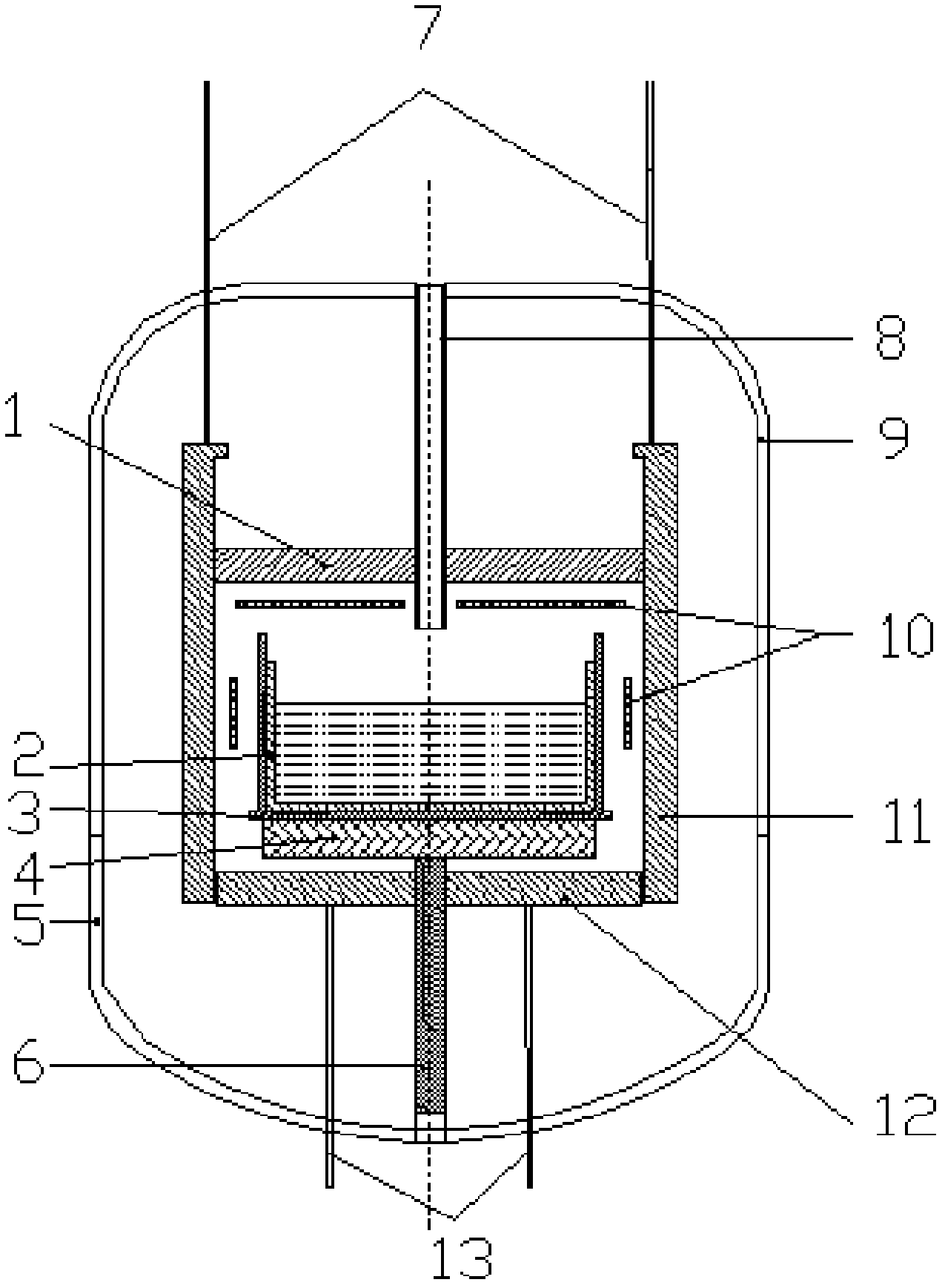

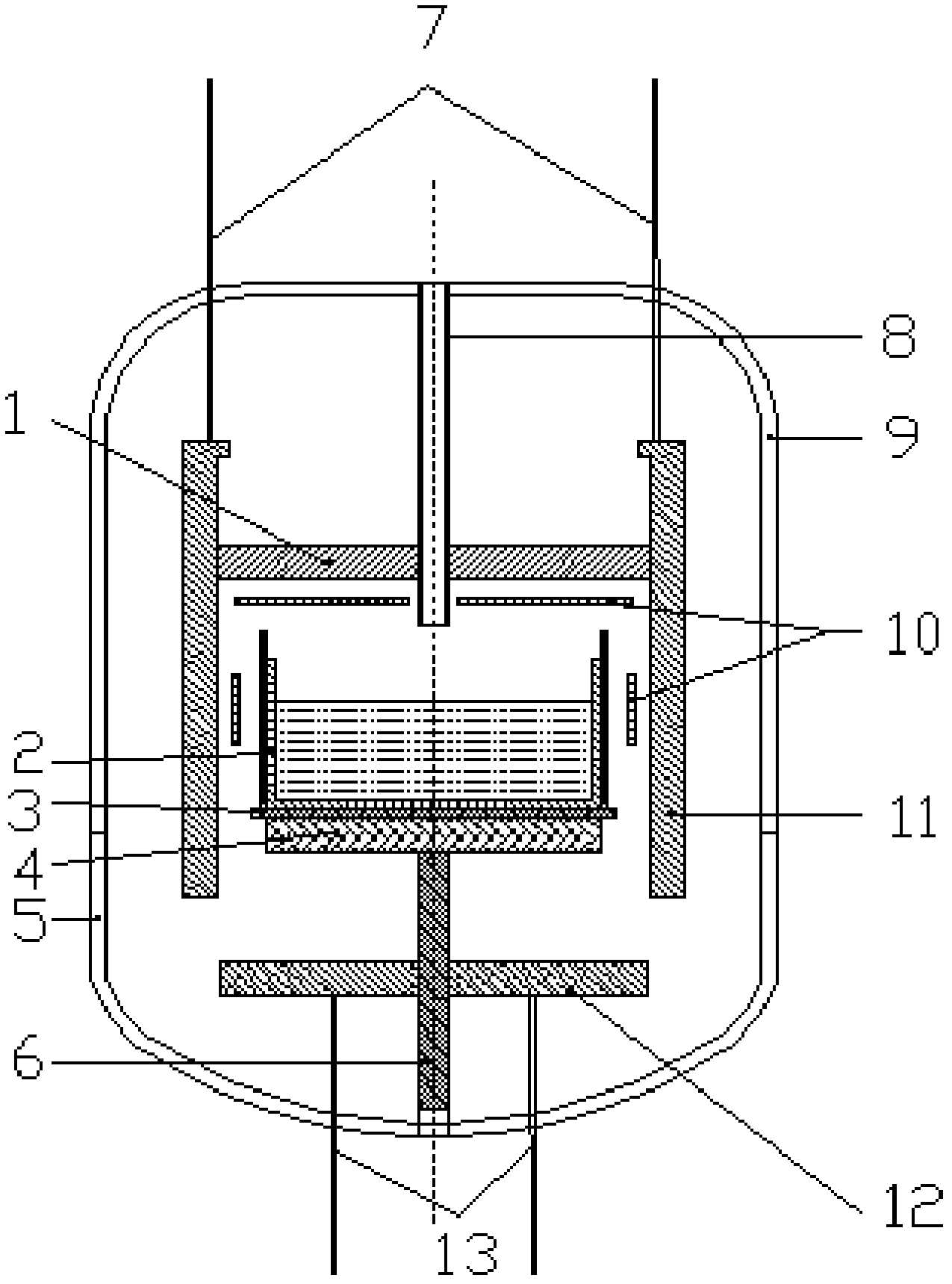

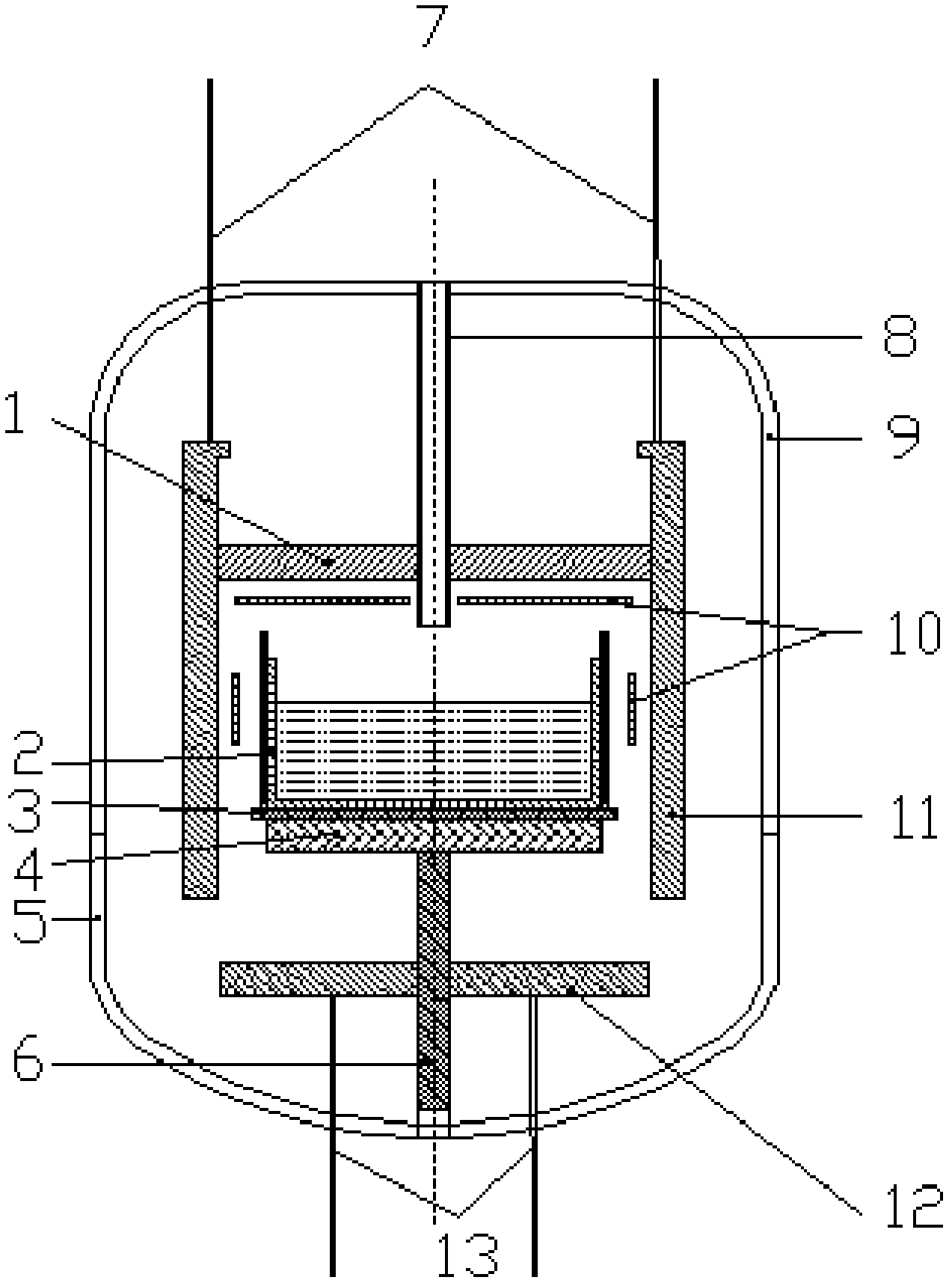

Method and thermal field for growing ingot polycrystal silicon by adopting directional solidification method

A directional solidification, polycrystalline silicon technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of convex center, affecting crystal quality, large radial temperature gradient, etc., to reduce energy consumption and improve crystal quality , the effect of reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The zero point is set at 25 cm below the graphite-assisted clot.

[0019] 1) Before melting: the bottom plate of the heat preservation chamber and the side wall of the heat preservation chamber move up at the same time, and the two remain closed. The distance between the bottom plate of the heat preservation chamber and the graphite coagulation aid is 5cm; Help the space between the clots, so that the high-temperature melting stage, the high-temperature space is reduced to reduce heat dissipation, and achieve the effect of energy saving;

[0020] 2) Melting at high temperature, 0.5 hours after the melting is completed; the bottom plate of the heat preservation cavity and the side wall of the heat preservation cavity move down to zero at the same time; the distance between the bottom plate of the heat preservation cavity and the graphite coagulation aid is opened. Form a cold spot and form large-sized grains that expand from the center to the surroundings;

[0021] 3) C...

Embodiment 2

[0040] Take the closed position of the melting stage as the zero point.

[0041] Process step is similar to embodiment 1, no longer enumerates in detail here, and concrete process parameter is as shown in table 2:

[0042] stage

[0043] The test results show that under the same charging amount, the melting and annealing stage can save 316kwh of electricity, which is about 21% lower than that of the same period last year. Under the same battery process, the conversion efficiency of the silicon wafer is increased by 0.12 percentage points.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com