Method for immersing collapsed loess site

A collapsible loess and site technology, applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as affecting building safety, reducing sliding resistance, long time, etc., to prevent water running” and piercing , the effect of eliminating adverse effects and reducing the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

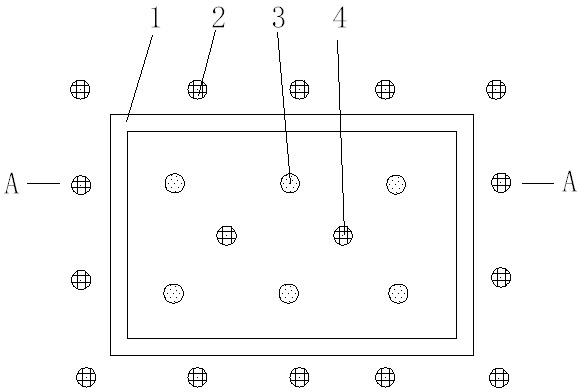

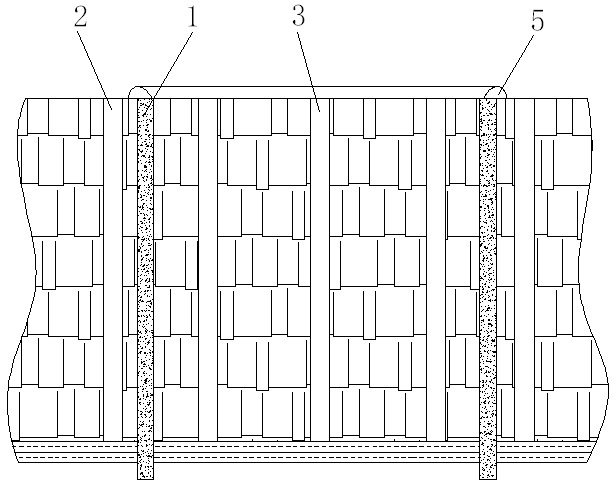

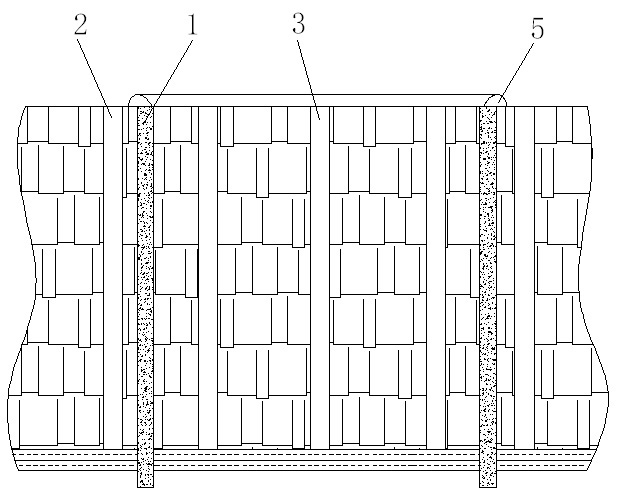

[0018] as attached figure 1 , 2 As shown, the construction technology of the flooding method for the collapsible loess site:

[0019] 1. Arrange the underground pile wall 1 according to the location of the fence wall in the approved engineering construction drawing, so that the underground pile wall forms a complete closed circle, that is, the piercing type water-proof curtain. The upper end of the underground pile wall is flush with the ground, and the lower end of the underground pile wall must penetrate the collapsible soil layer and enter the water-resistant layer for 0.5 meters. In this way, when flooding and subsidence are carried out, the water in the site is blocked from penetrating to the outside of the site; the underground pile wall is made of cement concrete;

[0020] 2. Set pumping wells 2 at intervals of 50 meters within 5 meters outside the circle of the underground pile wall;

[0021] 3. Set water seepage sand well 3 and internal pumping well 4 in the underg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com