Plate-type heat exchanger

A technology of plate heat exchanger and baffle plate, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., can solve the problems of heat exchange parameters that cannot be changed, heavy weight, and many metal consumables, etc. To achieve the effect of convenient production and replacement at any time, low density and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

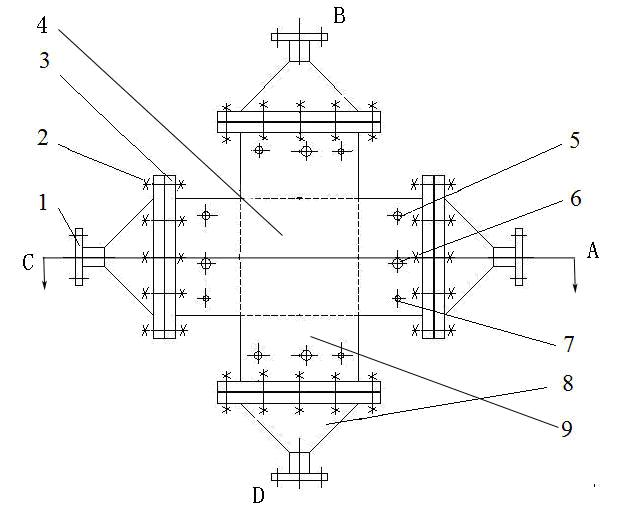

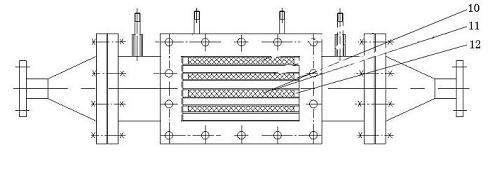

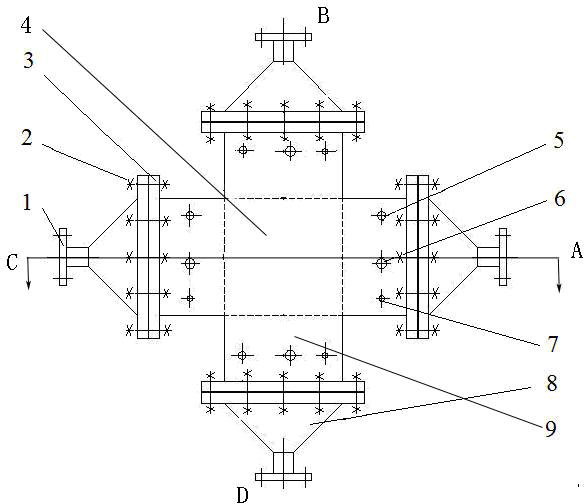

[0011] cold and hot fluids from figure 1 The A and B shown in the shell enter, and flow through the heat exchange zone 4 inside the square tube box 9 in a cross shape for heat exchange. The function of the Dg50 connecting flange 1, connecting bolt 2 and tube box flange 3 is to The tube box 9 and the tapered tube box 8 are fixed and sealed, and the heat exchange zone 4 is mainly composed of figure 2 The metal foam plate 10, the partition plate 11, and the baffle plate 12 are composed of the metal foam plate 10, the partition plate 11, and the baffle plate 12, and the cold and hot fluids are layered and sealed in multiple layers. The foam metal inside the foam metal plate 10 is through-hole, which can flow through the liquid medium fluid. The rear baffle plate 12 of the foam metal plate 10 is used to fix the foam metal plate 10 and prevent the high-pressure fluid from causing the foam metal plate 10 to deflect. shift. figure 1 Among them, the temperature measuring port 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com