A kind of preparation method of silicon nanowire

A technology of silicon nanowires and top silicon, which is used in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of high process requirements and high photolithography process requirements, and achieves simple process preparation methods, wide application prospects, and convenience. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

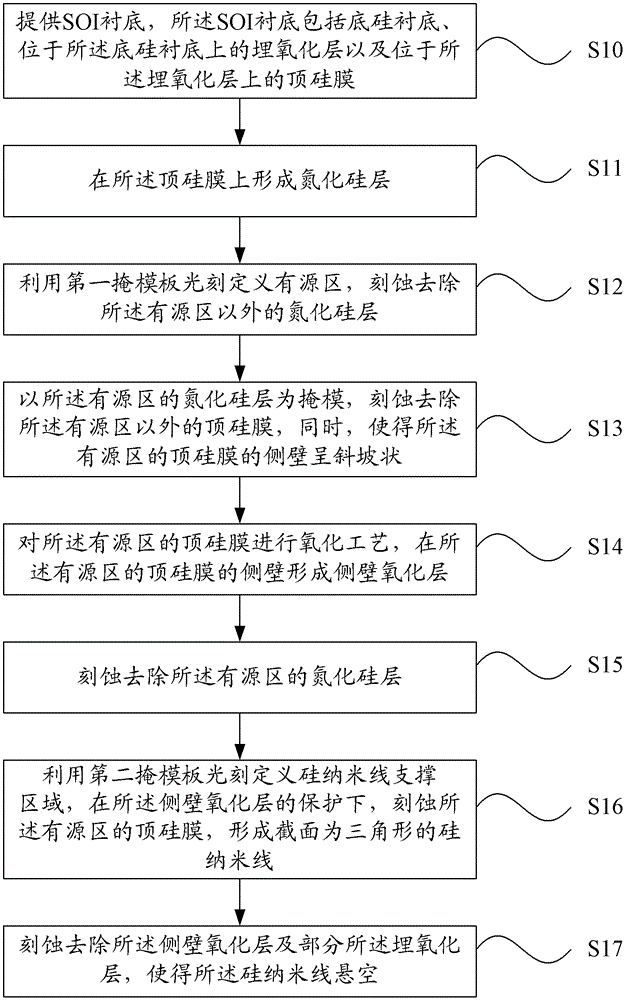

[0040] Please refer to figure 1 , which is a block diagram of a method for preparing silicon nanowires according to an embodiment of the present invention. Such as figure 1 Shown, the preparation method of described silicon nanowire comprises the steps:

[0041] S10: providing an SOI substrate, where the SOI substrate includes a bottom silicon substrate, a buried oxide layer on the bottom silicon substrate, and a top silicon film on the buried oxide layer;

[0042]S11: forming a silicon nitride layer on the top silicon film;

[0043] S12: Define an active region by photolithography using the first mask, and etch and remove the silicon nitride layer outside the active region;

[0044] S13: Using the silicon nitride layer in the active region as a mask, etch and remove the top silicon film outside the active region, and at the same time, make the sidewall of the top silicon film in the active region slope-shaped;

[0045] S14: performing an oxidation process on the top silic...

Embodiment 1

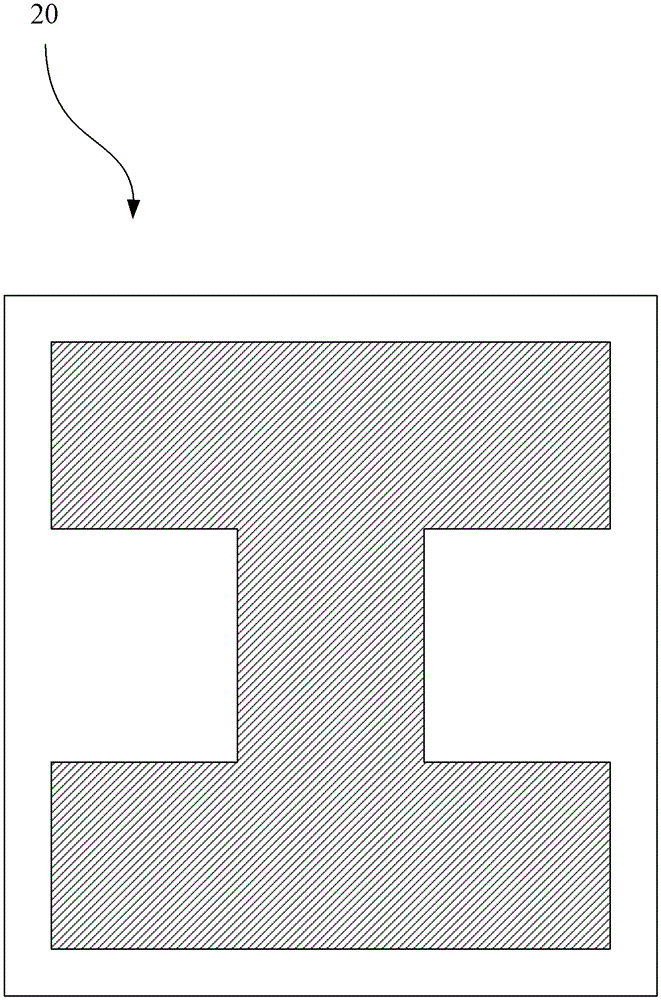

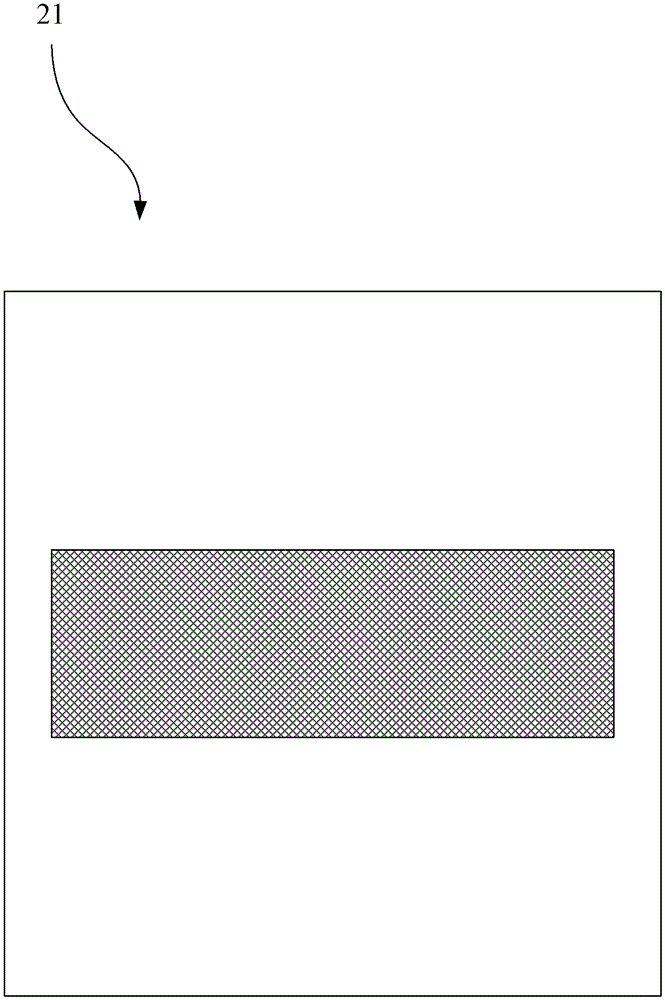

[0054] Please refer to Figure 2a-2c , Figure 3a~3h and Figure 4 ,in, Figure 2a is a schematic top view of the first mask used in the method for preparing silicon nanowires in Example 1 of the present invention; Figure 2b is a schematic top view of the second mask used in the method for preparing silicon nanowires in Example 1 of the present invention; Figure 2c It is a schematic diagram of registration with the first mask when the second mask is used in the method for preparing silicon nanowires in Embodiment 1 of the present invention; Figure 3a~3h It is the preparation method of the silicon nanowire according to the first embodiment of the present invention. Figure 2c Schematic diagram of the cross-sectional process in the direction indicated by AA' in the middle; Figure 4 It is the preparation method of the silicon nanowire according to the first embodiment of the present invention. Figure 2c The schematic cross-sectional view of the direction indicated by B...

Embodiment 2

[0065] Please refer to Figures 5a-5c and Image 6 ,in, Figure 5a is a schematic top view of the first mask used in the method for preparing silicon nanowires in Example 2 of the present invention; Figure 5b is a schematic top view of the second mask used in the method for preparing silicon nanowires in Example 2 of the present invention; Figure 5c It is a schematic diagram of registration with the first mask when the second mask is used in the method for preparing silicon nanowires according to Embodiment 2 of the present invention; Image 6 It is the preparation method of the silicon nanowire according to the second embodiment of the present invention. Figure 5c The schematic cross-sectional view in the direction indicated by AA'.

[0066] The difference between this embodiment and Embodiment 1 is that the first mask 40 used (such as Figure 5a Shown) the graphics include a plurality of "I" fonts connected in sequence. And the used second mask 41 (such as Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com