Traversing device

A technology of reciprocating device and reciprocating motion, used in electromechanical devices, cooling/ventilation devices, transportation and packaging, etc., can solve the problems of complex structure, the possibility of torque increase, and the inability to provide structural space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

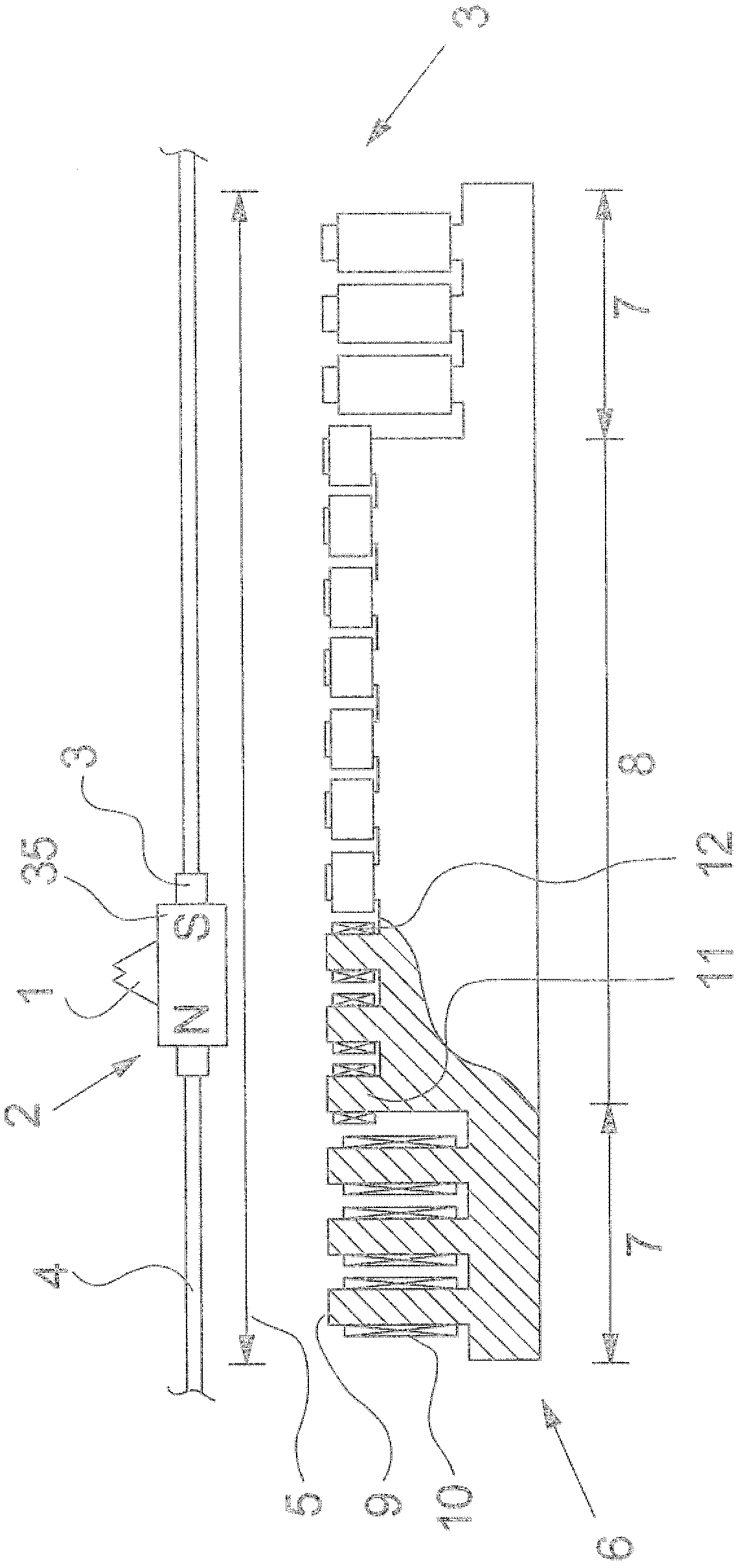

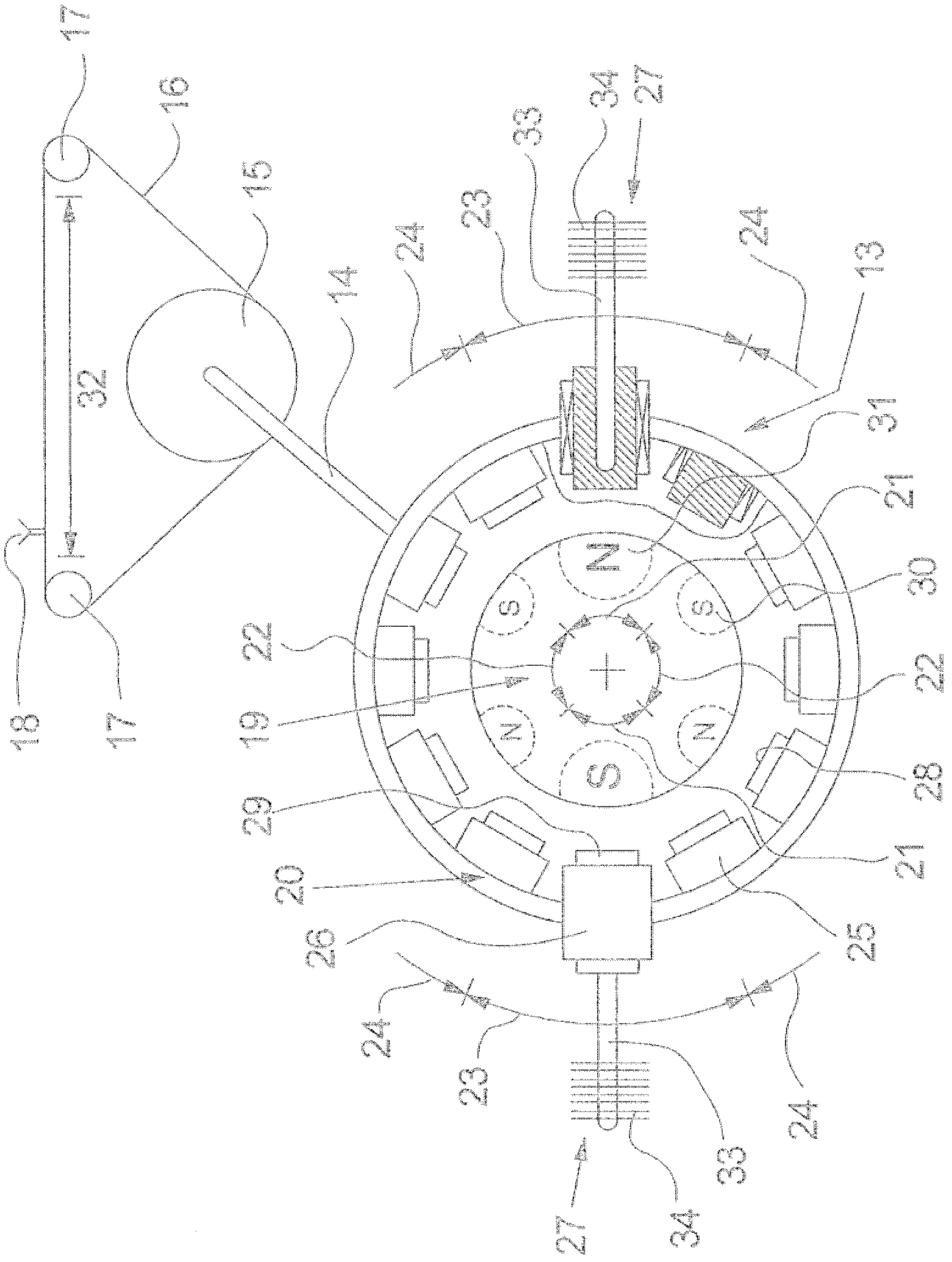

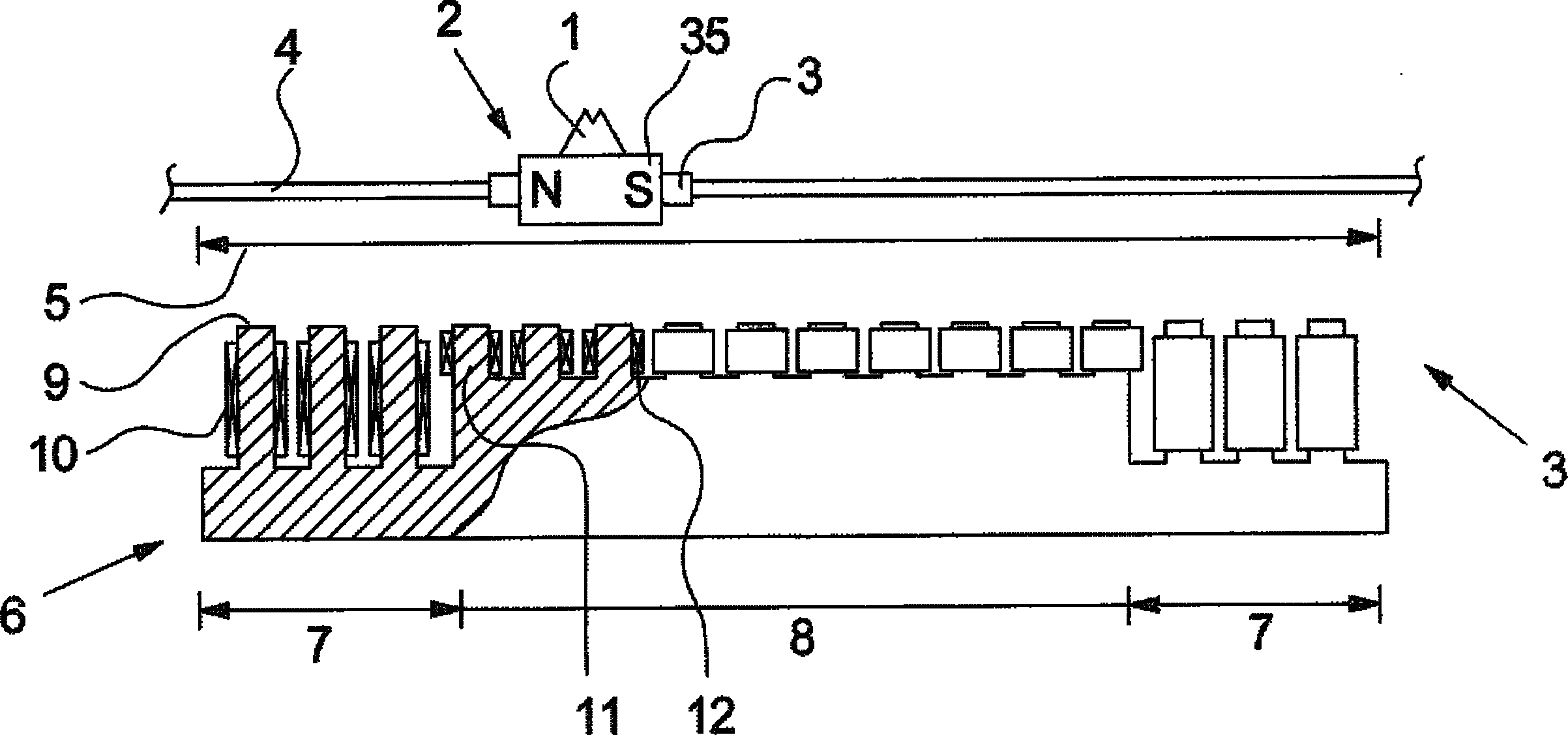

[0028] exist figure 1 shows a reciprocating device according to the invention with a drive implemented by a linear motor. The mover 2 , which is designed as a permanent magnet 35 , is guided on the guide 4 via the sleeve 3 , so that it can be guided back and forth within the reciprocating region 5 . The mover 2 carries a reciprocating yarn guide 1 for guiding the yarn to and fro by the mover 2 inside the reciprocating area 5 when winding the yarn bobbin.

[0029] The mover 2 interacts with a stator 6 which is equipped with a plurality of yokes 9 , 11 and coils 10 , 12 . The coils 10 , 11 are connected to a controllable alternating current source, so that a magnetic field is created that migrates in the longitudinal direction of the stator 6 , said magnetic field pushing the mover 2 . Here the AC power is controlled such that the direction of motion is reversed at each end of the reciprocating zone.

[0030] The region in which the direction of movement is reversed is referr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com