Vacuum conveying cotton picker

A cotton picker and vacuum technology, which is applied in the field of vacuum conveying cotton pickers, can solve the problems of low harvesting efficiency and poor picking effect, and achieve the effects of high picking efficiency, light operation and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

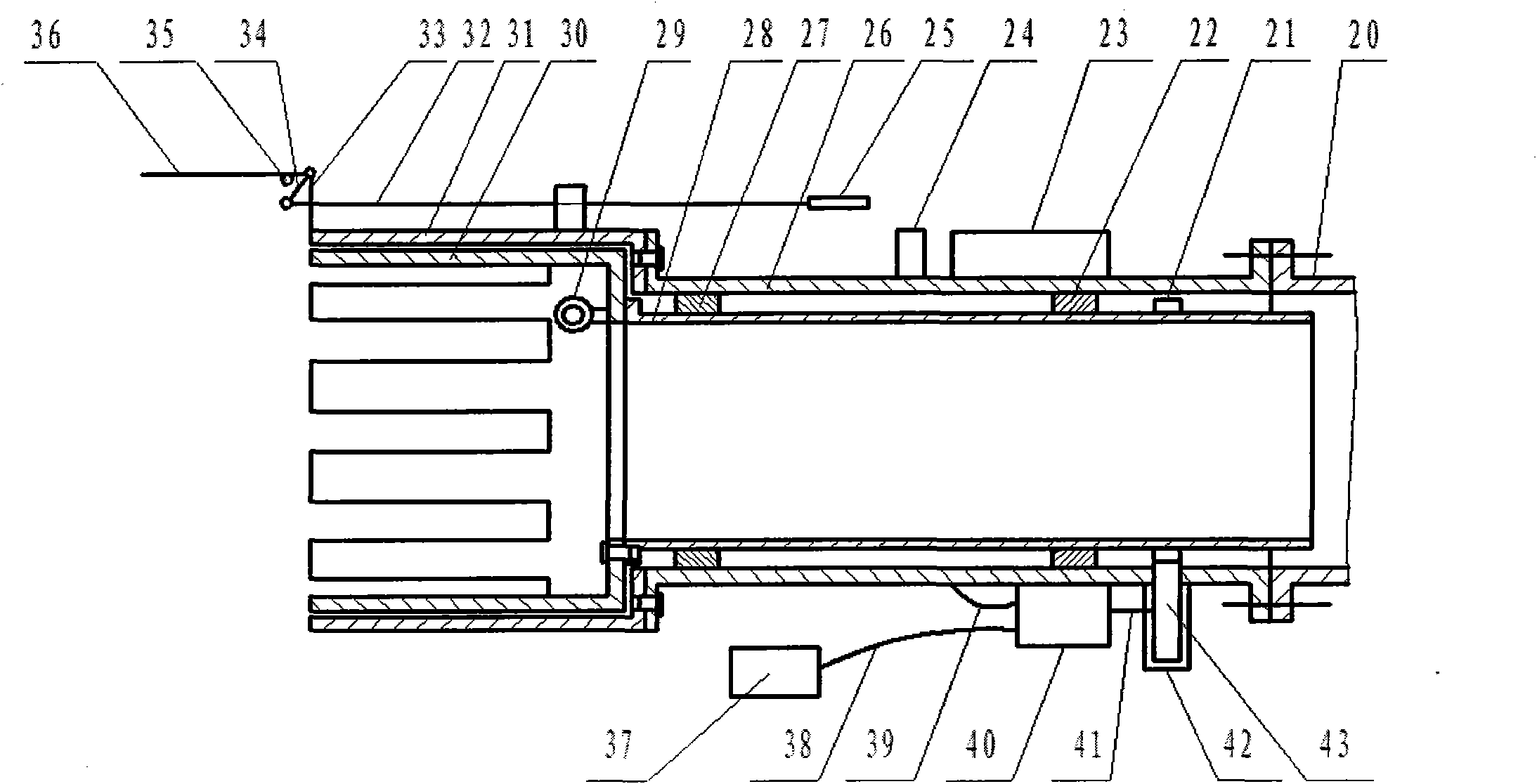

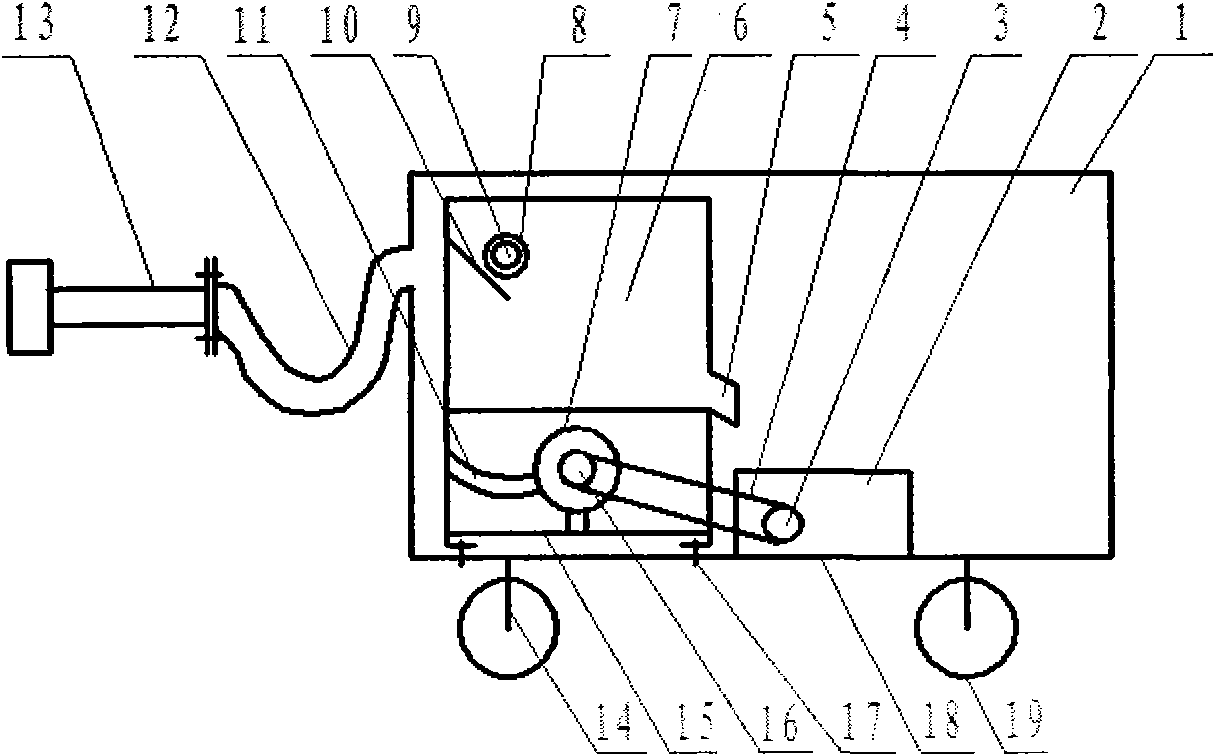

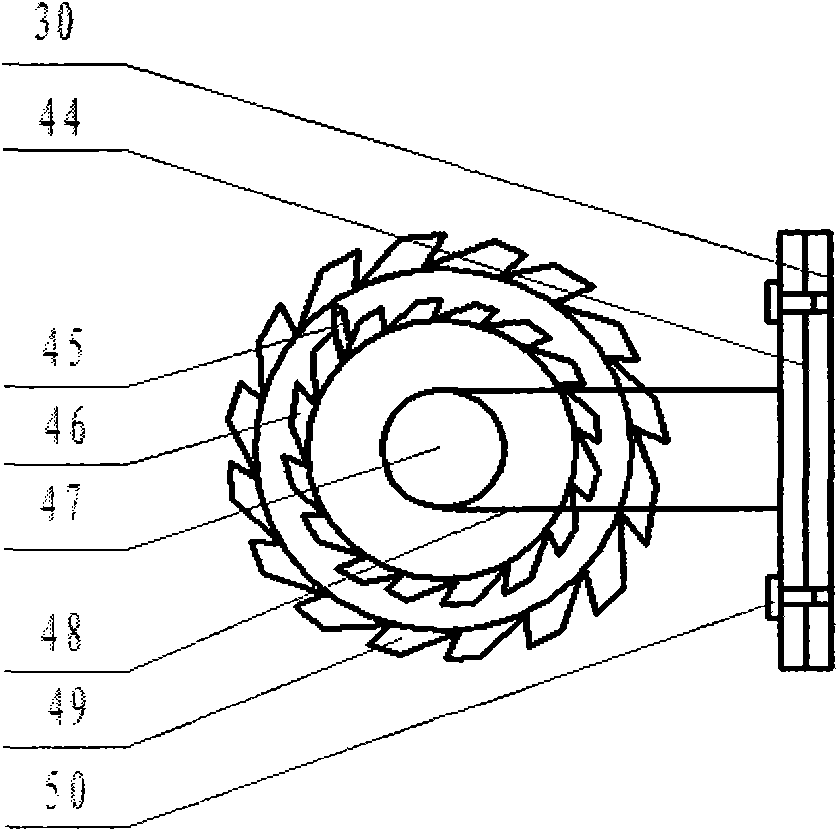

[0011] A vacuum conveying cotton picking machine, which consists of a cotton box 1, a diesel engine 2, a diesel engine pulley 3, a belt 4, a cotton outlet 5, a vacuum chamber 6, a blower 7, a filter 8, an air inlet 9, and a cotton protection board 10. Air extraction pipe 11, cotton suction pipe 12, picker 13, wheel frame 14, vacuum chamber support 15, blower pulley 16, bottom plate screw 17, cotton box bottom plate 18, wheels 19, cotton suction pipe joint 20, large gear 21. Lower bearing 22, handle 23, switch 24, pull ring 25, outer fixing tube 26, upper bearing 27, inner fixing tube 28, ratchet and pawl combination 29, moving knife 30, fixed knife 31, iron wire 32, cotton retaining Plate bracket 33, lever rotating shaft combination 34, spring 35, cotton baffle plate 36, battery 37, battery motor wire 38, motor switch wire 39, motor 40, motor shaft 41, gear cover 42, pinion 43, ratchet bottom plate 44, ratchet Claw spring combination 45, inner ratchet 46, ratchet shaft 47, rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com