Flexible control device for pneumatically conveying tobacco shreds and control method

A control device and pneumatic conveying technology, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of unstable flow state, high shredding rate of cut tobacco, fluctuation of pressure and air volume, etc., to improve measurement and control. Accuracy, reducing the rate of shredded tobacco, and reducing the effect of shredding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

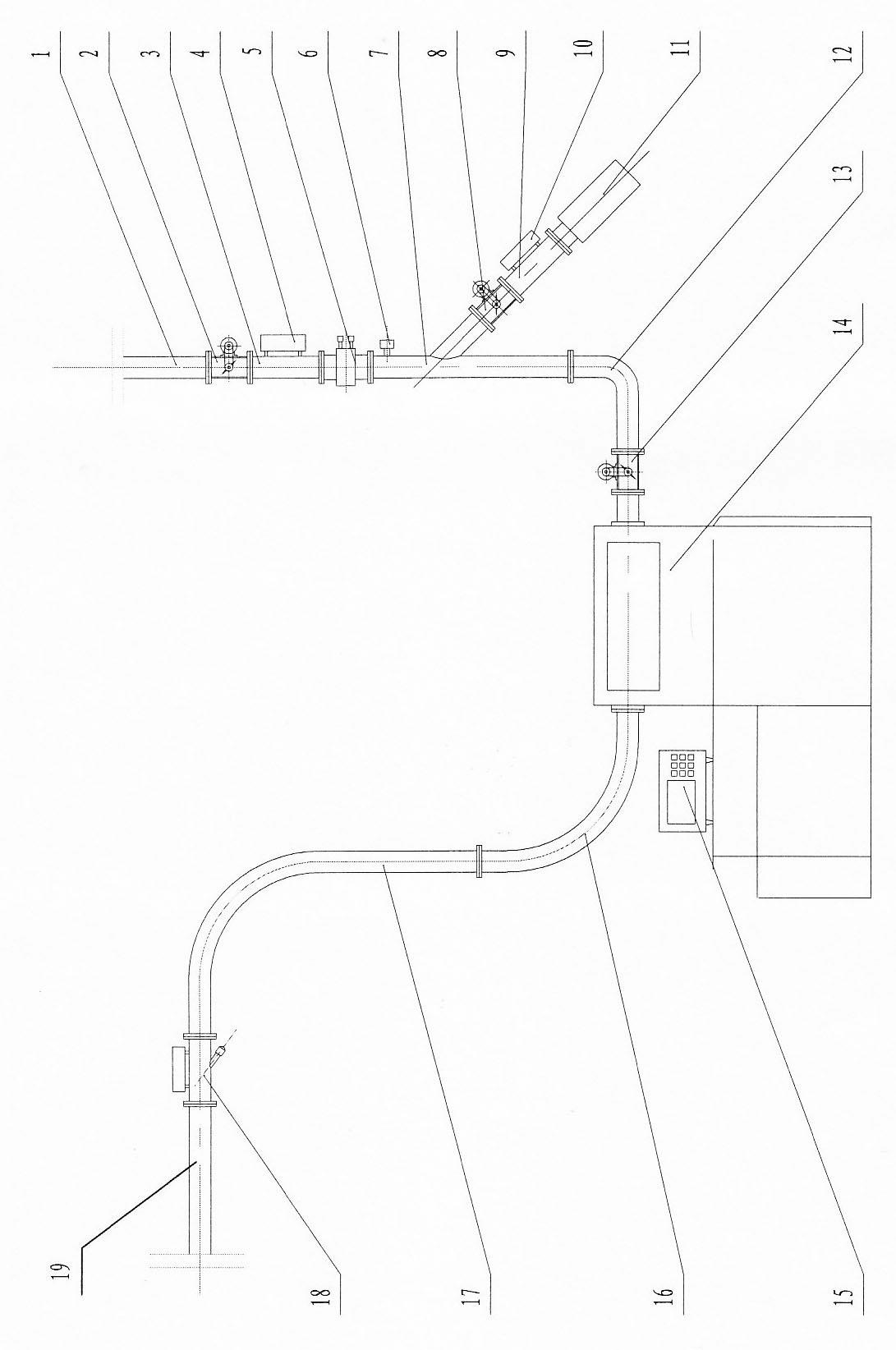

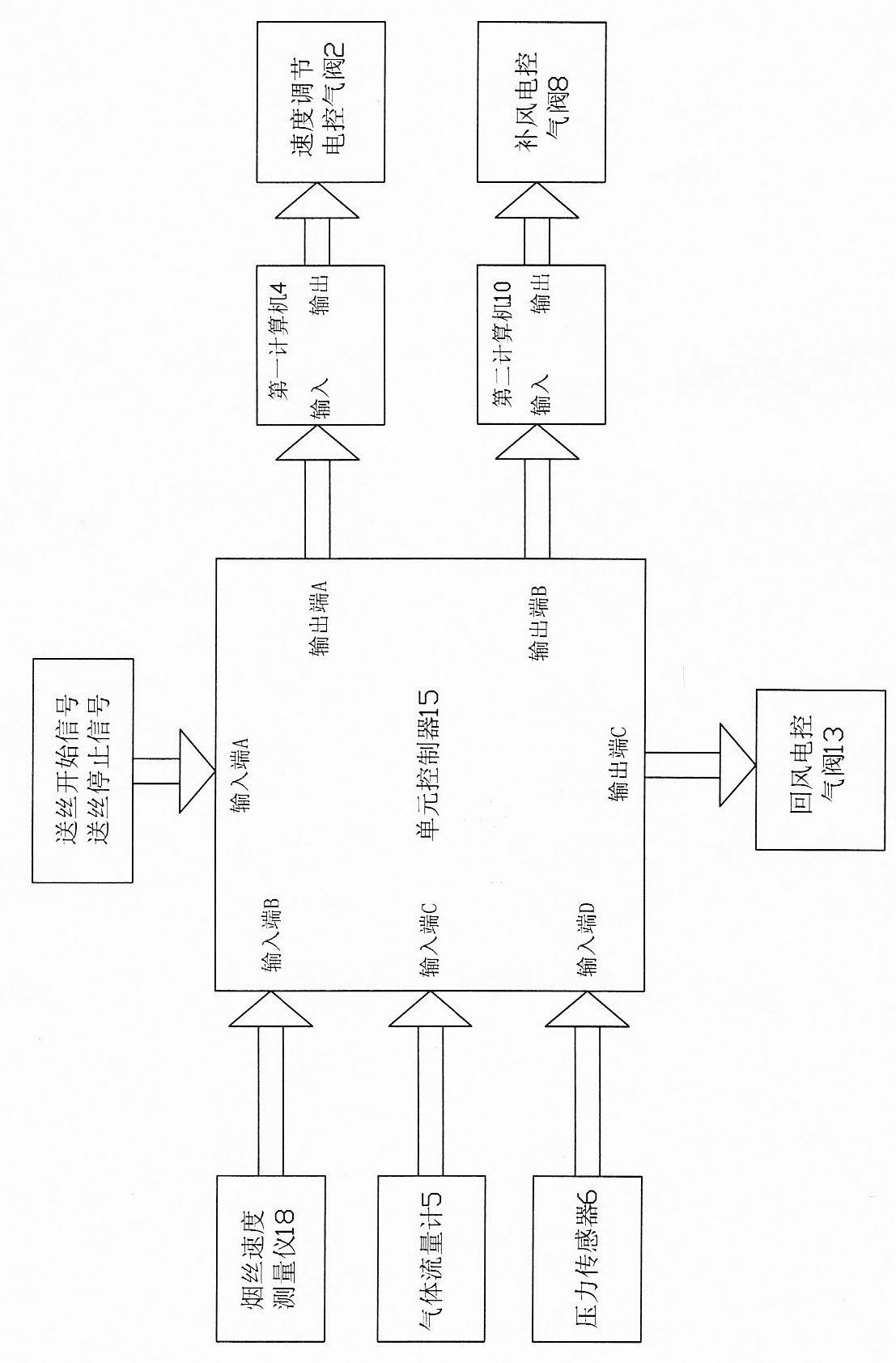

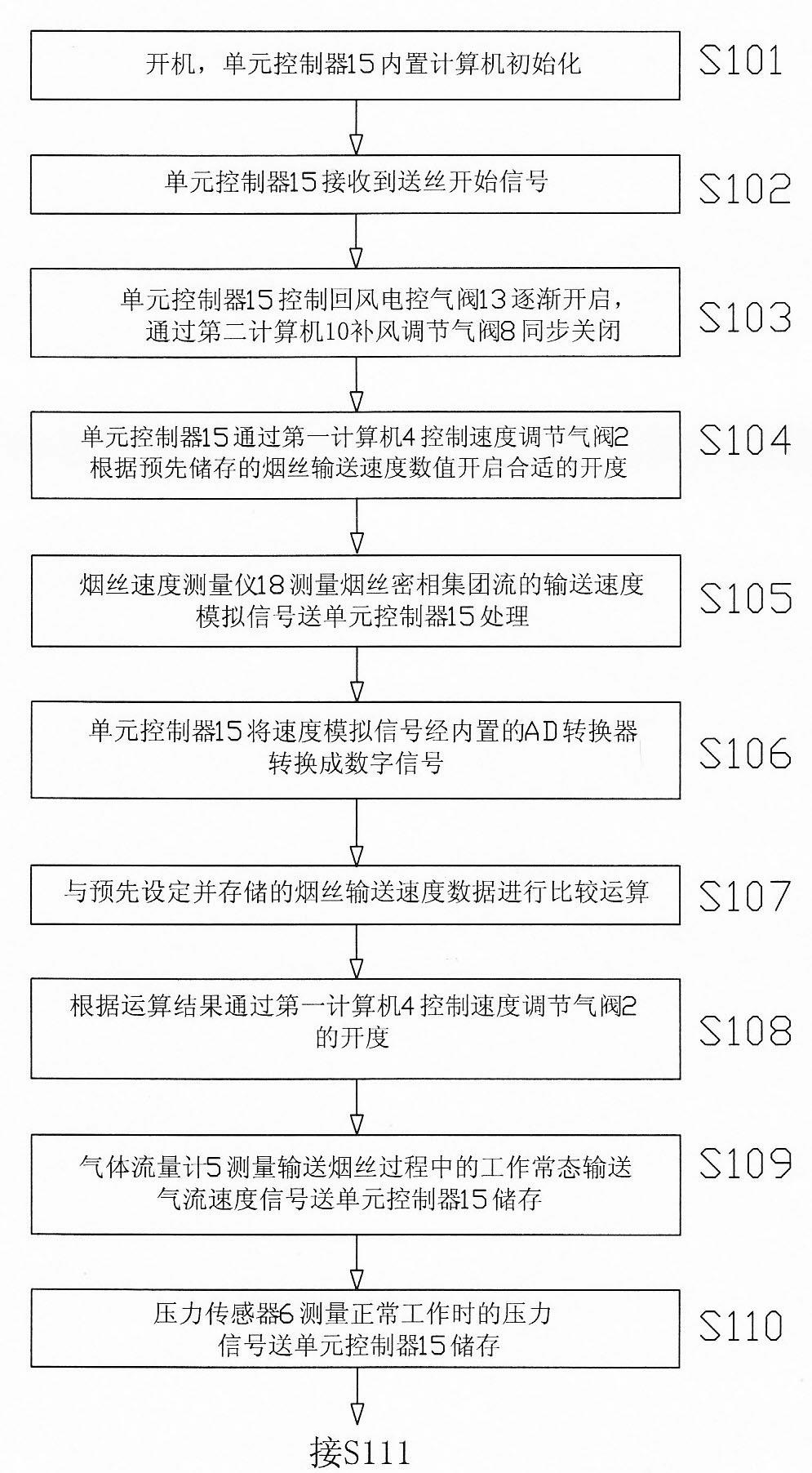

[0051] A flexible control device for pneumatically conveying shredded tobacco speed, which includes a speed regulating air valve 2 installed between the dust removal pipe port on the cigarette collecting box 14 and the dust removal pipe 1, a first gas rectifier 3, a first computer 4, a gas Flow meter 5, pressure sensor 6, air manifold 7, supplementary air regulating air valve 8, second gas rectifier 9, second computer 10, air filter 11, dust removal pipe elbow 12, return air electric control air valve 13 and The first shredded tobacco delivery pipe bend 16 , the second shredded tobacco delivery pipe bend 17 and the shredded tobacco speed measuring instrument 18 are installed between the shredded tobacco delivery pipe port on the shredded tobacco collecting box 14 of the cigarette making machine and the shredded tobacco delivery pipe 19 .

[0052] The inlet of the dust removal pipe 1 is connected to the outlet of the speed regulating gas valve 2, the inlet of the speed regulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com