Full-automatic numerical-control porridge and soup stewing machine

A fully automatic porridge cooking technology, applied in the direction of non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., can solve the problems of affecting the taste of food, adjusting heating methods, and not having power-off protection, so as to avoid mistakes The operation causes danger, the food nutrition is completely released, and the effect of power-off protection function is increased

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

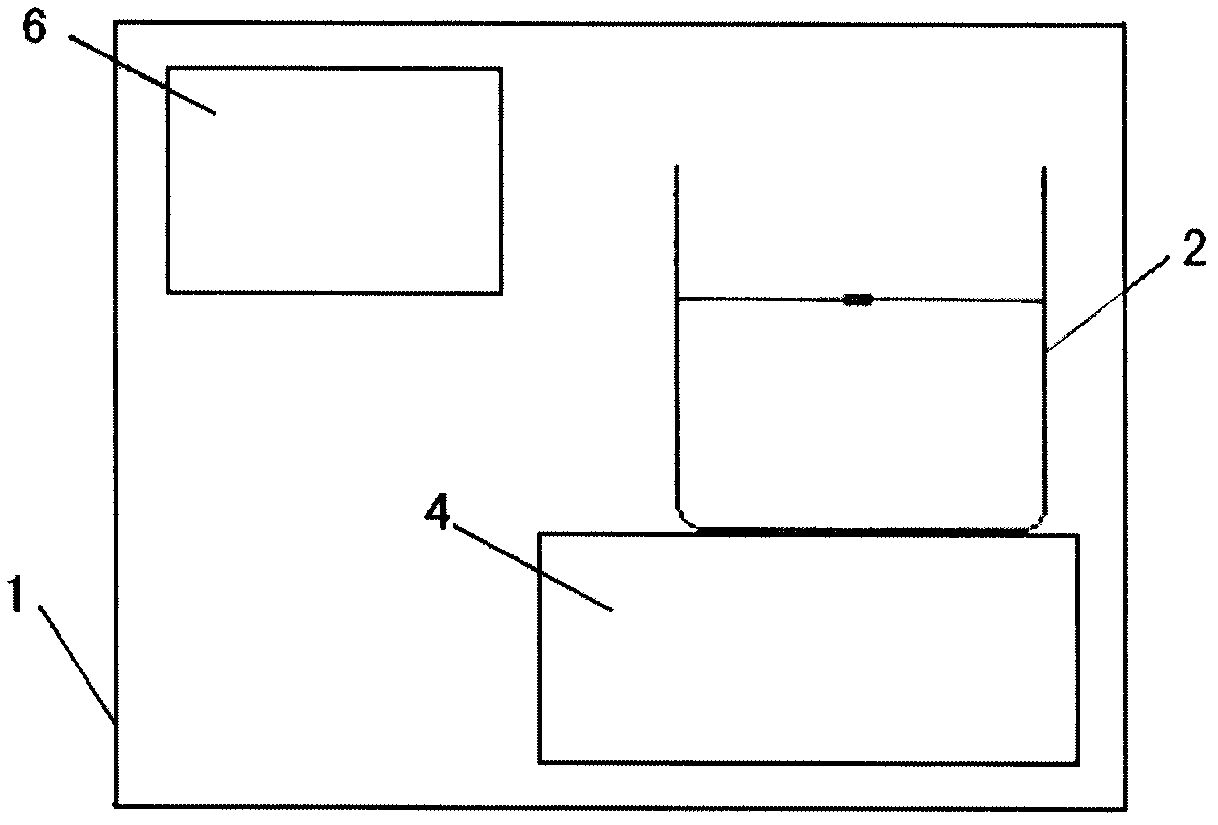

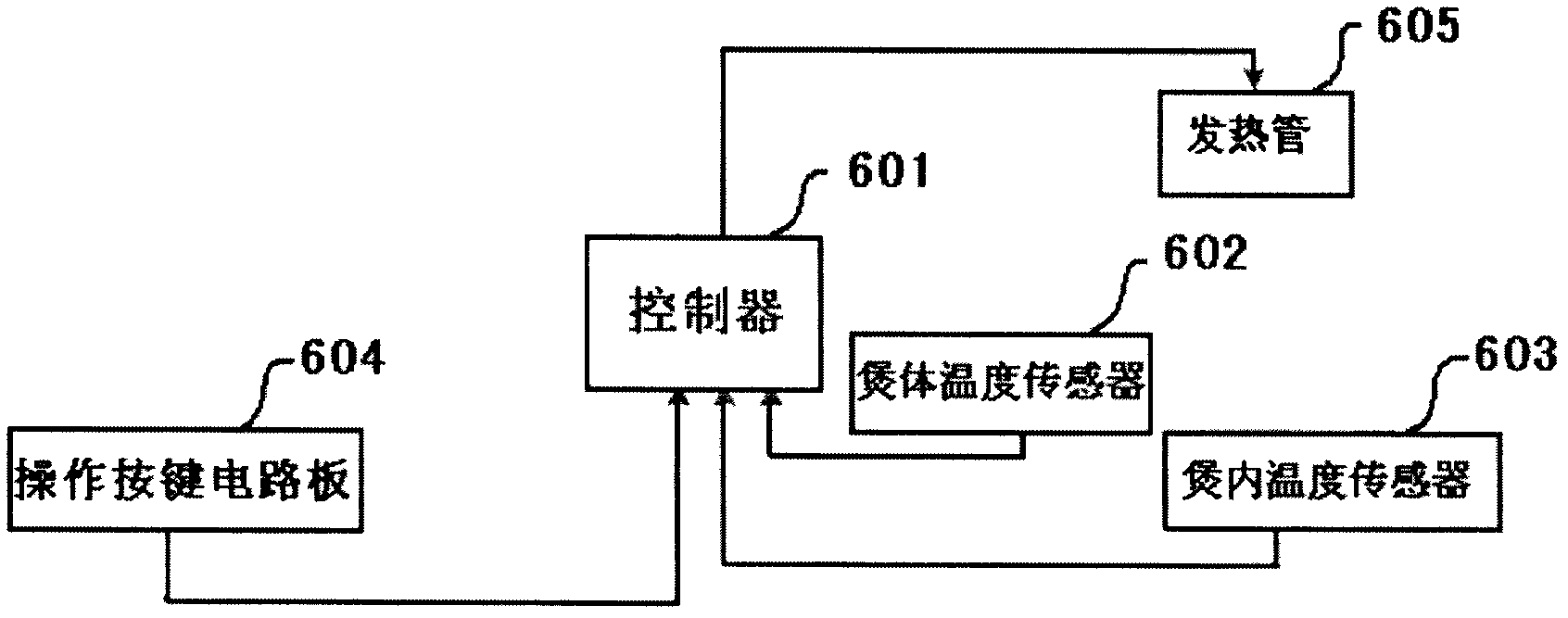

[0033] Such as figure 1 As shown, the porridge and soup cooking machine provided by the present invention includes a casing 1 , a pot body 2 and a heating device 4 disposed in the casing 1 , wherein the heating device 4 is disposed below the pot body 2 . In order to realize fully automatic operation of the entire cooking process, an electrical control system 6 is arranged in the casing 1 . The composition of this electrical control system 6 is as follows: figure 2 shown. The entire electrical control system 6 mainly includes a controller 601 , a temperature sensor 602 for a pot body, a temperature sensor 603 inside a pot, an operation button circuit board 604 and at least one heating tube 605 . The body temperature sensor 602, the temperature sensor 603 inside the pot, the operation button circuit board 604 and the heat pipe 605 are respectively connected with and controlled by the controller. The heating pipe 605 is arranged in the heating device 4, and its function is to...

Embodiment 2

[0036] In another preferred embodiment provided by the present invention, a water adding device 3 is added on the basis of the above-mentioned embodiment 1. Such as Figure 5 As shown, the water adding device 3 is connected to the pot body 2 through the pot body water inlet pipe 5 . The water adding device 3 is preferably an automatic water adding device, which includes a water injection cavity 301, a first water level monitoring device 302 is provided on the top of the water injection cavity 301, and a second water level monitoring device 204 is provided on the top of the pot body 2. The device 3 is connected to the water supply device 7 through the first water inlet pipe 303 . The water supply device 7 here can be a faucet or other devices that can provide water required for cooking food. The first water inlet pipe 303 is provided with a first water inlet control valve 304 for controlling water entering into the water adding device 3, and the pot body water inlet pipe 5 is...

Embodiment 3

[0039] On the basis of Embodiment 1, another preferred embodiment is provided. Such as Figure 7 As shown, in this preferred embodiment, the heating device 4 includes a steam generator 401, and the steam generator 401 is connected to the pot body 2 through at least one steam delivery pipe 402, and the steam delivery pipe 402 will The water vapor generated by the steam generator 401 is passed into the pot body 2 to achieve the purpose of heating food. The steam generator 401 is also provided with a water inlet, and the water inlet is connected with the water supply device 7 through a second water inlet pipe 403 . The water supply device 7 here can be a faucet or other devices that can provide water required for cooking food. The steam delivery pipe 402 is provided with a steam delivery pipe check valve 4021, and the second water inlet pipe 403 is provided with a second water inlet pipe check valve 4031, and the second water inlet pipe 403 is close to the water supply device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com