Laying method of nano carbon crystal water heating modules

A technology of nano-carbon crystals and laying method, which is applied in hot water central heating system, heating method, lighting and heating equipment, etc., can solve problems such as large damage to power supply lines, large resistance of heating elements, and safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

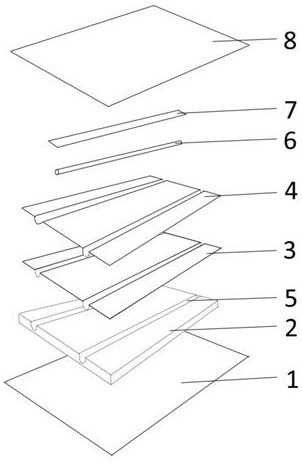

Image

Examples

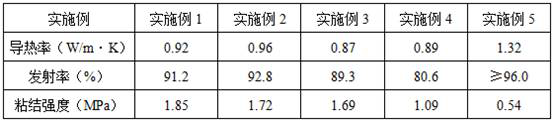

Embodiment 1

[0047] The nano-carbon crystal layer is coated on the heat-conducting aluminum plate through a spraying process. Described spraying process comprises the steps:

[0048] Surface treatment of graphene: First, disperse graphene and dispersant in ferric chloride solution under the action of ultrasonic waves, and continue to react for 3 hours under nitrogen protection under low boiling conditions, and finally add dilute hydrochloric acid to remove nanometer particles in the solution. Grade iron oxide particles, washed with water until neutral, filtered, and dried for use; then the above-mentioned graphene and dispersant were dispersed in isopropanol under the action of ultrasonic waves to form a suspension, and then the silane coupling agent KH- 570 solution, in which the mass ratio of graphene to silane coupling agent KH-570 is 1:1.5; then, under the condition of reflux at 85°C, keep stirring for 4h, then filter, wash with water, and dry to obtain black silylated graphite alkene...

Embodiment 2

[0054] The nano-carbon crystal layer is coated on the heat-conducting aluminum plate through a spraying process. Described spraying process comprises the steps:

[0055] Surface treatment of graphene: first, disperse graphene and dispersant in ferric chloride solution under the action of ultrasonic waves, and continue to react for 2 hours under nitrogen protection under low boiling conditions, and finally add dilute hydrochloric acid to remove nanometer particles in the solution. Grade iron oxide particles, washed with water until neutral, filtered, and dried for use; then the above-mentioned graphene and dispersant were dispersed in isopropanol under the action of ultrasonic waves to form a suspension, and then the silane coupling agent KH- 570 solution, in which the mass ratio of graphene to silane coupling agent KH-570 is 1:1; then, under reflux conditions at 80°C, continue stirring for 5 hours, then filter, wash with water, and dry to obtain black silylated graphite alken...

Embodiment 3

[0061] The nano-carbon crystal layer is coated on the heat-conducting aluminum plate through a spraying process. Described spraying process comprises the steps:

[0062] Surface treatment of graphene: First, disperse graphene and dispersant in ferric chloride solution under the action of ultrasonic waves, and continue to react for 5 hours under nitrogen protection under low boiling conditions, and finally add dilute hydrochloric acid to remove nanometer particles in the solution. Grade iron oxide particles, washed with water until neutral, filtered, and dried for use; then the above-mentioned graphene and dispersant were dispersed in isopropanol under the action of ultrasonic waves to form a suspension, and then the silane coupling agent KH- 570 solution, in which the mass ratio of graphene to silane coupling agent KH-570 is 1:2; then, under the condition of reflux at 90°C, keep stirring for 3h, then filter, wash with water, and dry to obtain black silylated graphite alkene. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com