Production method of semiconductor gas sensor for seafood freshness detection

A gas sensor, freshness technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of high detection concentration, long response/recovery time, poor selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

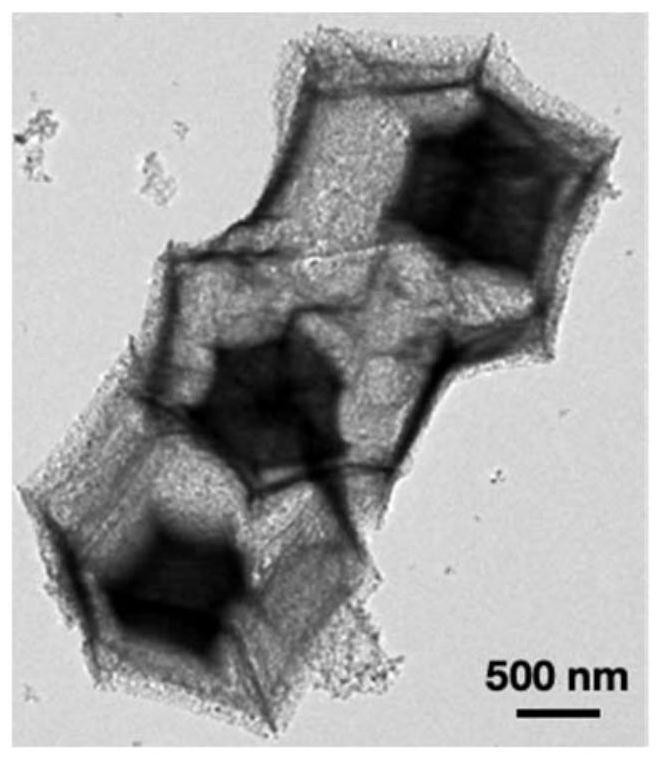

[0025] 1) Prepare 120mmol / L aqueous solution of cobalt acetate dihydrate and 6mol / L aqueous solution of dimethylimidazole respectively, take 10mL aqueous solution of zinc acetate dihydrate and aqueous solution of dimethylimidazole respectively, mix them well and evenly in equal volumes to obtain the The mixed solution was placed at room temperature for 30 minutes, the precipitate in the mixed solution was centrifuged, washed, and dried under vacuum conditions to obtain the product ZIF67;

[0026] 2) Take 20 mg of the product in step 1 and disperse it into 5 mL of an aqueous solution of dimethylimidazole with a concentration of 1.9 mol / L to obtain a mixed solution A;

[0027] 3) Take the zinc acetate dihydrate aqueous solution with a concentration of 120mmol / L, and add it to the mixed solution A obtained in step 2, wherein the volume ratio of the zinc acetate dihydrate aqueous solution to solution A is 1:1, mix well and put it at room temperature 30min. The precipitate in the ...

Embodiment 2

[0036] This example is similar to example 1, except that in step 2), 5 mg of the product of step 1 is taken and dispersed into 5 mL of a dimethylimidazole aqueous solution with a concentration of 1.9 mol / L to obtain a mixed solution A.

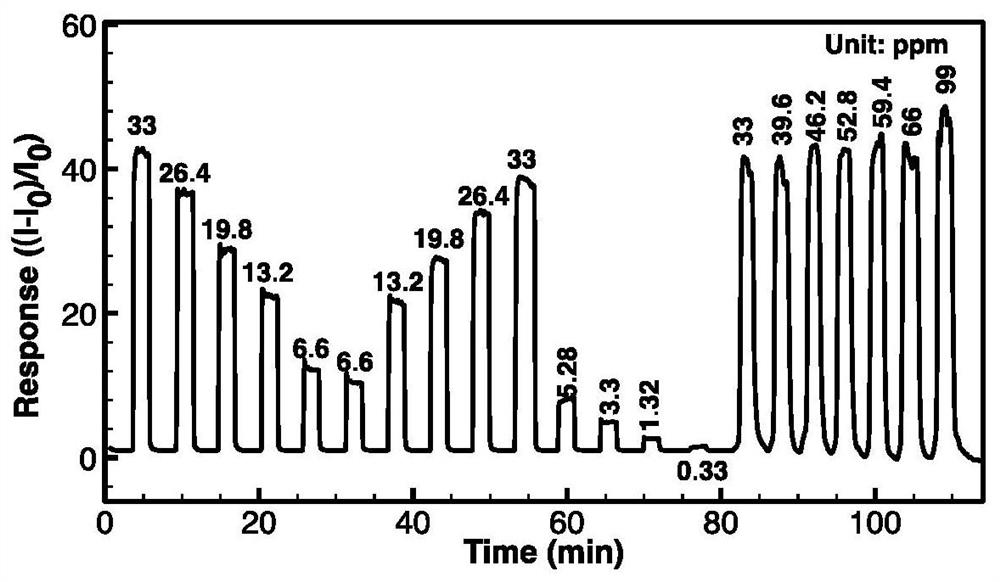

[0037] The sensitive response / recovery curves of the gas sensor prepared in embodiment 2 to different concentrations of trimethylamine gas are as follows Figure 6 shown.

Embodiment 3

[0039] This example is similar to Example 1, except that step 4) calcines the ZIF core-shell nanomaterial prepared in step 3 in air at 380°C for 2h, and the heating rate is 1.5°C / min to obtain porous and hollow Co 3 o 4 @ZnO core-shell structure.

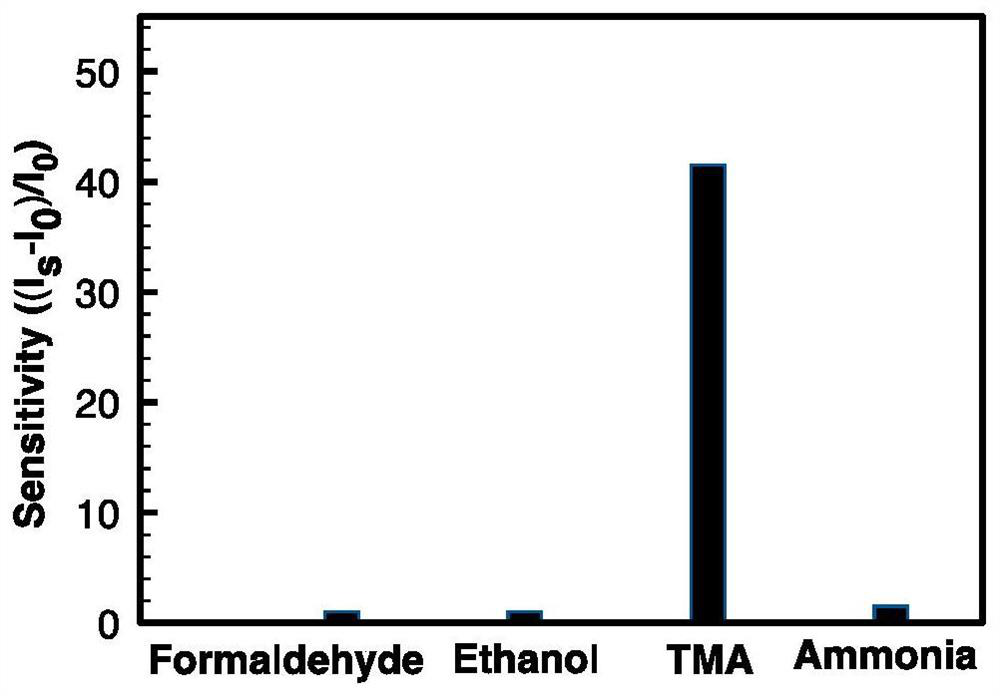

[0040] The present invention adopts static gas distribution method to measure the sensitivity characteristic of semiconductor sensor, and the sensitivity when detecting gas is defined as (I s -I 0 ) / I 0 , among them, I s Indicates the current value of the sensor in a certain concentration of gas to be detected , I 0 Indicates the current value of the sensor in the background gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com