A process for reducing organic solvent residues in heparin sodium

The technology of an organic solvent and a process method is applied in the technical field of reducing the residual organic solvent in heparin sodium, and can solve the problems such as the instability of the residual index of the organic solvent, so as to prevent the color of the product from yellowing, the heating process is mild, and the protection from damage is achieved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

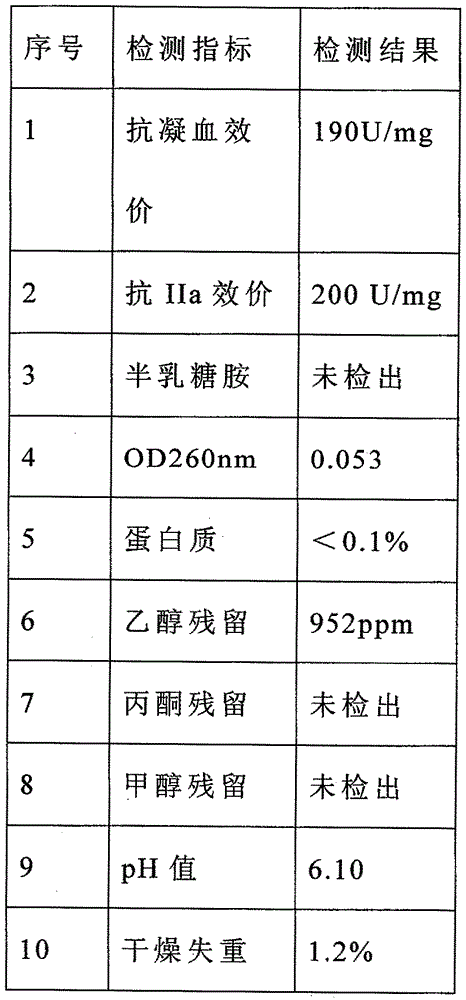

Image

Examples

Embodiment Construction

[0019] The following examples illustrate the invention in detail:

[0020] 1. Add 100Kg (about 12 billion units) of the wet solid obtained through the refining process into 360Kg of purified water to fully dissolve;

[0021] 2. Adjust the pH of the heparin sodium aqueous solution obtained in step 1 to 6.0, and lower the temperature to 8°C;

[0022] 3. Cool 90% ethanol to -12°C;

[0023] 4. Under stirring conditions, add the ethanol in step 3 to the heparin sodium aqueous solution in step 2 until the ethanol concentration is 65%;

[0024] 5. After siphoning the upper layer of ethanol, centrifuge the precipitate in step 4 and shake it dry;

[0025] 6. Add absolute ethanol until the ethanol concentration is 95%, and let stand for more than 10 hours;

[0026] 7. After siphoning the upper layer of ethanol again, centrifuge the lower layer of sediment and dry it to obtain the wet product of heparin sodium;

[0027] 8. Under vacuum conditions, dry the wet product of heparin sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com