Preparation and application of photocatalyst LaOF

A technology of lanthanum oxyfluoride and photocatalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc. The effect of simple and easy promotion and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

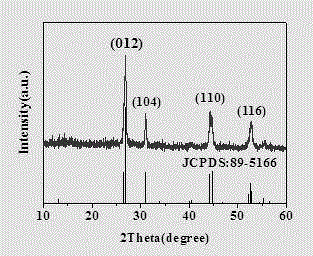

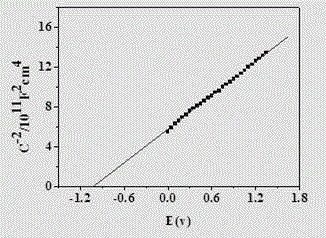

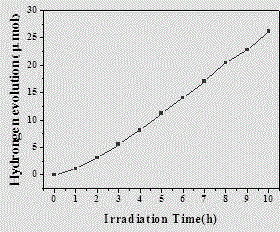

Image

Examples

preparation example Construction

[0016] The preparation method of this photocatalyst is the synthetic method of hydrothermal-heat treatment: concrete steps are as follows:

[0017] (1) Preparation of the precursor: Dissolve the fluoride solid as the fluorine source: ammonium fluoride or sodium fluoride in deionized water, ethylene glycol or ethanol, or a mixed solvent of two of them to obtain a concentration of 0.1~1 mol / L fluorine source solution; the compound solid as the lanthanum source: one of lanthanum oxide, lanthanum nitrate or lanthanum acetate dissolved in one or both of deionized water, ethylene glycol or ethanol Prepare a lanthanum source solution with a concentration of 0.01-0.1 mol / L in a mixed solvent; add the fluorine source solution dropwise while stirring in the lanthanum source solution, and continue stirring for 30-180 minutes to obtain a white turbid liquid, which is transferred to a high-pressure reaction kettle for 90 React at a constant temperature of ~180°C for 12-24 hours, wash the p...

Embodiment 1

[0020] Preparation of LaOF catalyst

[0021] Weigh 0.0127 mol NH 4 The F solid was dissolved in 40 mL of deionized water and stirred for 2 min to give NH 4 F solution; another 0.0061 mol La 2 o 3 The solid was dissolved in 40 mL deionized water, and an appropriate amount of NH was added dropwise while stirring 4 F solution, continue to stir for 30 minutes, transfer the obtained white turbid liquid into a high-pressure reactor, keep the temperature at 180°C for 18 hours, centrifuge the obtained precipitate, wash, dry at 40°C for 24 hours, calcinate at 300°C for 6 hours, and finally grind A white LaOF powder was obtained.

Embodiment 2

[0023] Preparation of LaOF catalyst

[0024] Weigh 0.0127 mol NH 4 The F solid was dissolved in 40 mL of deionized water and stirred for 2 min to give NH 4 F solution; another 0.0061 mol La 2 o 3 The solid was dissolved in 40 mL deionized water, and an appropriate amount of NH was added dropwise while stirring 4 F solution, continue to stir for 3 hours, transfer the obtained white turbid liquid into a high-pressure reactor, keep the temperature at 135°C for 24 hours, centrifuge the obtained precipitate, wash, dry at 120°C for 6 hours, calcinate at 800°C for 4 hours, and finally grind A white LaOF powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com