Preparation method and application of Pt supported lanthanide fluoride-oxide photo-catalyst

A technology of lanthanum oxyfluoride and photocatalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc. The effect of simple and easy promotion and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of Pt / LaOF Catalyst

[0023] Weigh 0.0127 mol NH 4 The F solid was dissolved in 40 mL of deionized water and stirred for 2 minutes to obtain NH 4 F solution; another 0.0061 mol La 2 o 3 The solid was dissolved in 40mL deionized water, and an appropriate amount of NH was added dropwise while stirring. 4 F solution, continue to stir for 0.5 hours, transfer to an autoclave at 120°C for 24 hours at a constant temperature, centrifuge, wash, dry at 40°C, calcinate at 300°C for 6 hours, and grind to obtain white LaOF powder. The prepared LaOF was immersed in different volumes of chloroplatinic acid (1mg Pt / ml) solution, and after drying, it was reduced with 0.5mol / L sodium borohydride solution, washed, and dried at 40°C to obtain different loadings. The Pt / LaOF catalyst.

Embodiment 2

[0025] Preparation of Pt / LaOF Catalyst

[0026] Weigh 0.0127 mol NH 4 The F solid was dissolved in 40 mL of deionized water and stirred for 2 minutes to obtain NH 4 F solution; another 0.0061 mol La 2 o 3 The solid was dissolved in 40mL deionized water, and an appropriate amount of NH was added dropwise while stirring. 4 F solution was stirred for 3 hours, transferred to a high-pressure reactor at 180°C for 18 hours, and the resulting precipitate was centrifuged, washed, dried at 120°C, and calcined at 800°C for 5 hours, and ground to obtain white LaOF powder. The prepared LaOF was immersed in different volumes of chloroplatinic acid (20mg Pt / ml) solution, and after drying, it was reduced with 0.01mol / L sodium borohydride solution, washed, and dried at 80°C to obtain different loadings The Pt / LaOF catalyst.

Embodiment 3

[0028] Preparation of Pt / LaOF Catalyst

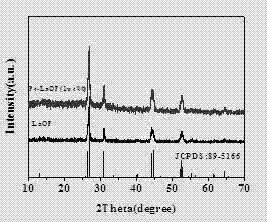

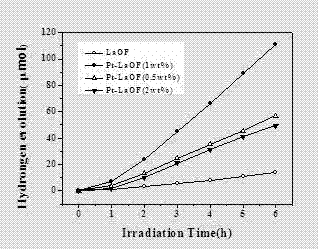

[0029] Weigh 0.0127 mol NH 4 The F solid was dissolved in 40 mL of deionized water and stirred for 2 minutes to obtain NH 4 F solution; another 0.0061 mol La 2 o 3 The solid was dissolved in 40mL deionized water, and an appropriate amount of NH was added dropwise while stirring. 4 F solution, continue to stir for 1 hour, move it into an autoclave at 90°C for 12 hours, centrifuge, wash, dry at 60°C, calcinate at 500°C for 3 hours, and grind to obtain white LaOF powder. The prepared LaOF was immersed in different volumes of chloroplatinic acid (10mg Pt / ml) solution, and after drying, it was reduced with 0.01~0.5mol / L sodium borohydride solution, washed, and dried at 120°C to obtain different Pt / LaOF catalysts with loading (0 wt% ~2 wt%). figure 1 The X-ray diffraction (XRD) patterns of Pt / LaOF and LaOF with a platinum loading of 1wt% of the new photocatalyst of the present invention are shown. Compared with the XRD pattern of LaOF, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com