Composite photo-catalyst and preparation method and application thereof

A photocatalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of restricting the practical application of photocatalytic technology, low quantum efficiency, low solar energy utilization rate, etc., to achieve It is conducive to large-scale promotion and the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, composite photocatalyst SnO x / LaCO 3 Preparation of OH

[0020] Weigh 0.006 mol CO(NH 2 ) 2 The solid was dissolved in 35 mL deionized water to prepare a urea solution; 0.001 mol La(NO 3 ) 3 ·6H 2 Dissolve the O solid in 35 mL deionized water to prepare a lanthanum nitrate solution; weigh 0.0001 mol SnCl 2 2H 2 O solid was dissolved in 35 mL of absolute ethanol to obtain stannous chloride alcohol solution; while stirring, urea solution and stannous chloride solution were successively added dropwise to the lanthanum nitrate solution, and the stirring was continued for 30 minutes, and the mixed solution was transferred to the high-pressure reaction In the kettle, keep the temperature at 90°C for 24 hours, cool down to room temperature naturally, centrifuge the obtained precipitate, wash, dry at 40°C under normal pressure for 24 hours, and grind to obtain light yellow SnO x / LaCO 3 OH composite photocatalyst powder.

Embodiment 2

[0021] Embodiment 2, composite photocatalyst SnO x / LaCO 3 Preparation of OH

[0022] Weigh 0.006 mol CO(NH 2 ) 2 The solid was dissolved in 35 mL deionized water to prepare a urea solution; 0.001 mol La(NO 3 ) 3 ·6H 2 Dissolve the O solid in 35 mL deionized water to prepare a lanthanum nitrate solution; weigh 0.001 mol SnCl 2 2H 2 O solid was dissolved in 35 mL of absolute ethanol to obtain stannous chloride alcohol solution; while stirring, urea solution and stannous chloride solution were successively added dropwise to the lanthanum nitrate solution, and the stirring was continued for 180 minutes, and the mixed solution was transferred to the high-pressure reaction In the kettle, keep the temperature at 180°C for 12 hours, cool down to room temperature naturally, centrifuge the obtained precipitate, wash, dry at 120°C under normal pressure for 24 hours and grind to obtain light yellow SnO x / LaCO 3 OH composite photocatalyst powder.

Embodiment 3

[0023] Embodiment 3, composite photocatalyst SnO x / LaCO 3 Preparation of OH

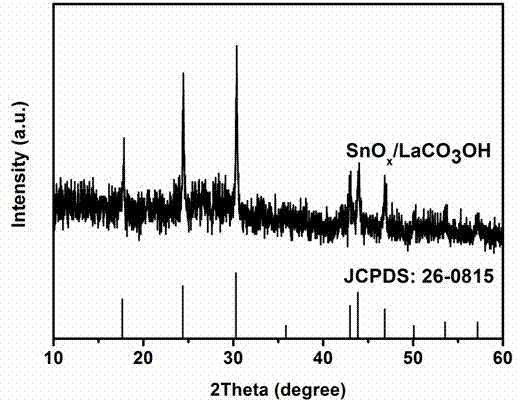

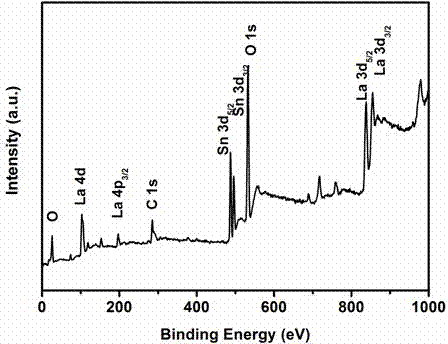

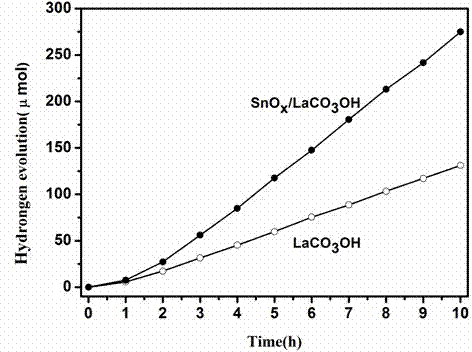

[0024] Weigh 0.006 mol CO(NH 2 ) 2 The solid was dissolved in 35 mL deionized water to prepare a urea solution; 0.001 mol La(NO 3 ) 3 ·6H 2 Dissolve the O solid in 35 mL deionized water to prepare a lanthanum nitrate solution; weigh 0.0005 mol SnCl 2 2H 2 O solid was dissolved in 35 mL of absolute ethanol to obtain stannous chloride alcohol solution; while stirring, urea solution and stannous chloride solution were successively added dropwise to the lanthanum nitrate solution, and the stirring was continued for 60 minutes, and the mixed solution was transferred to the high-pressure reaction In the kettle, keep the temperature at 120°C for 24 hours, cool down to room temperature naturally, centrifuge the obtained precipitate, wash, dry at 60°C under normal pressure for 24 hours, and grind to obtain light yellow SnO x / LaCO 3 OH composite photocatalyst powder. figure 1 Demonstrated the compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com