Mortar material storage method for mortar pump machine and mortar material storage device

A technology of mortar material and mortar pump, which is applied in the field of mortar material storage devices, can solve the problems of large volume of power stirring structure, lack of filtration, inconvenient access, etc., and achieve the goals of improving construction efficiency and quality, compact structure, and reducing construction labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

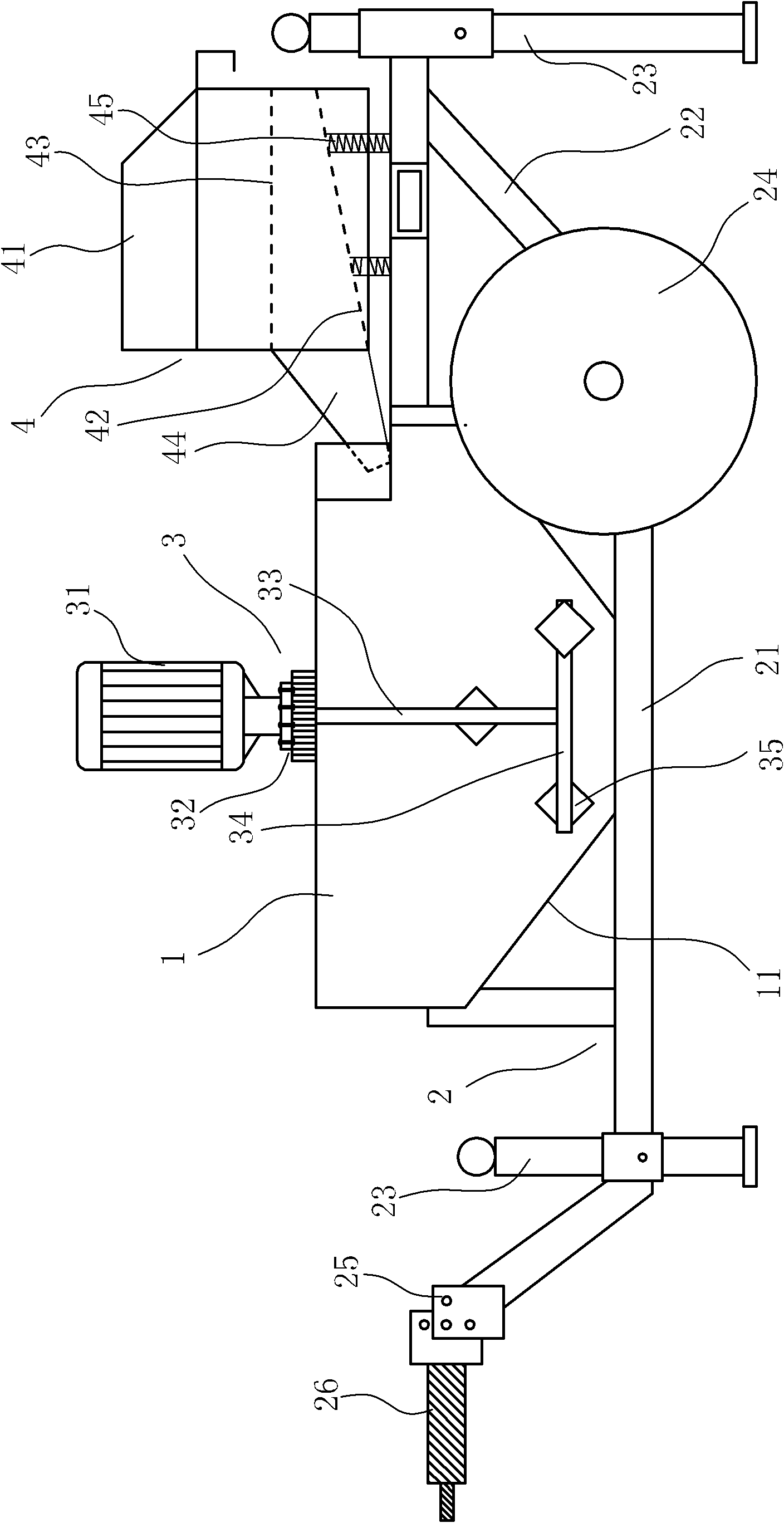

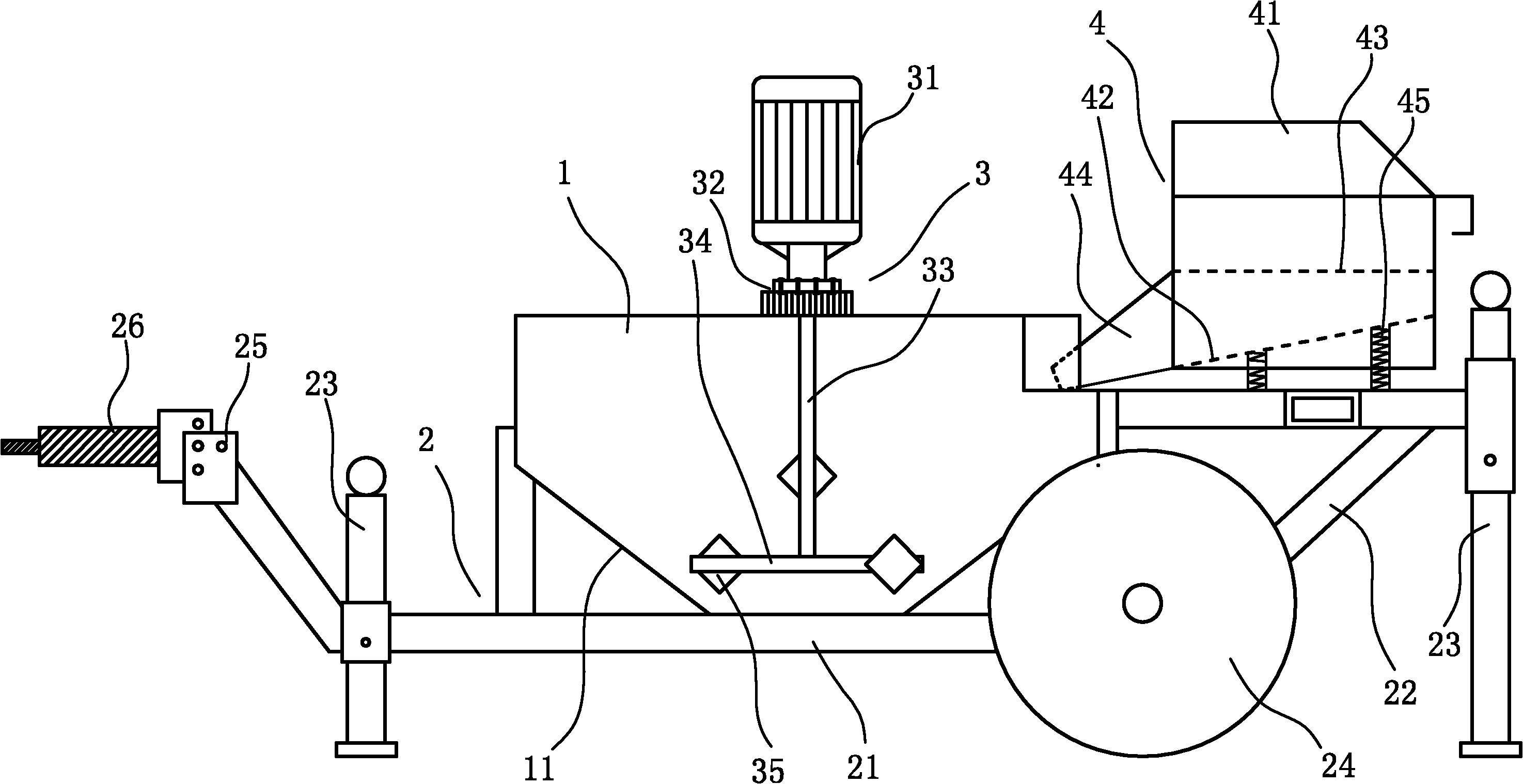

[0023] Example: see figure 1 , the present invention is used for the mortar material storage method of mortar pump, and it comprises the following steps:

[0024] (1) prepare an ash hopper 1 with an open top, fix the ash hopper 1 on a frame 2, and the lower half of the wall of the ash hopper 1 is an inclined plane 11 that is inclined and narrowed from the surroundings to the bottom surface. The inclined surface 11 of 1 is provided with a discharge pipe mouth matched with the feed pipe of the mortar pump machine near the bottom surface of the ash hopper 1;

[0025] (2) prepare a stirring device 3, this stirring device 3 comprises a motor 31, a reduction gear box 32, a stirring shaft 33, some stirring arms 34 and some stirring paddles 35, this stirring shaft 33 is passed through a support rotatably Set on the central axis of the ash hopper 1, the top of the stirring shaft 33 protrudes from the top of the ash hopper 1, the end of the stirring shaft 33 is close to the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com