Production equipment and production process for strong acidic electrolysis water

A technology of strong acid electrolyzed water and acid electrolyzed water, which is applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. and other problems, to achieve the effect of convenient operation, simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe an embodiment below in conjunction with accompanying drawing, the present invention is described further.

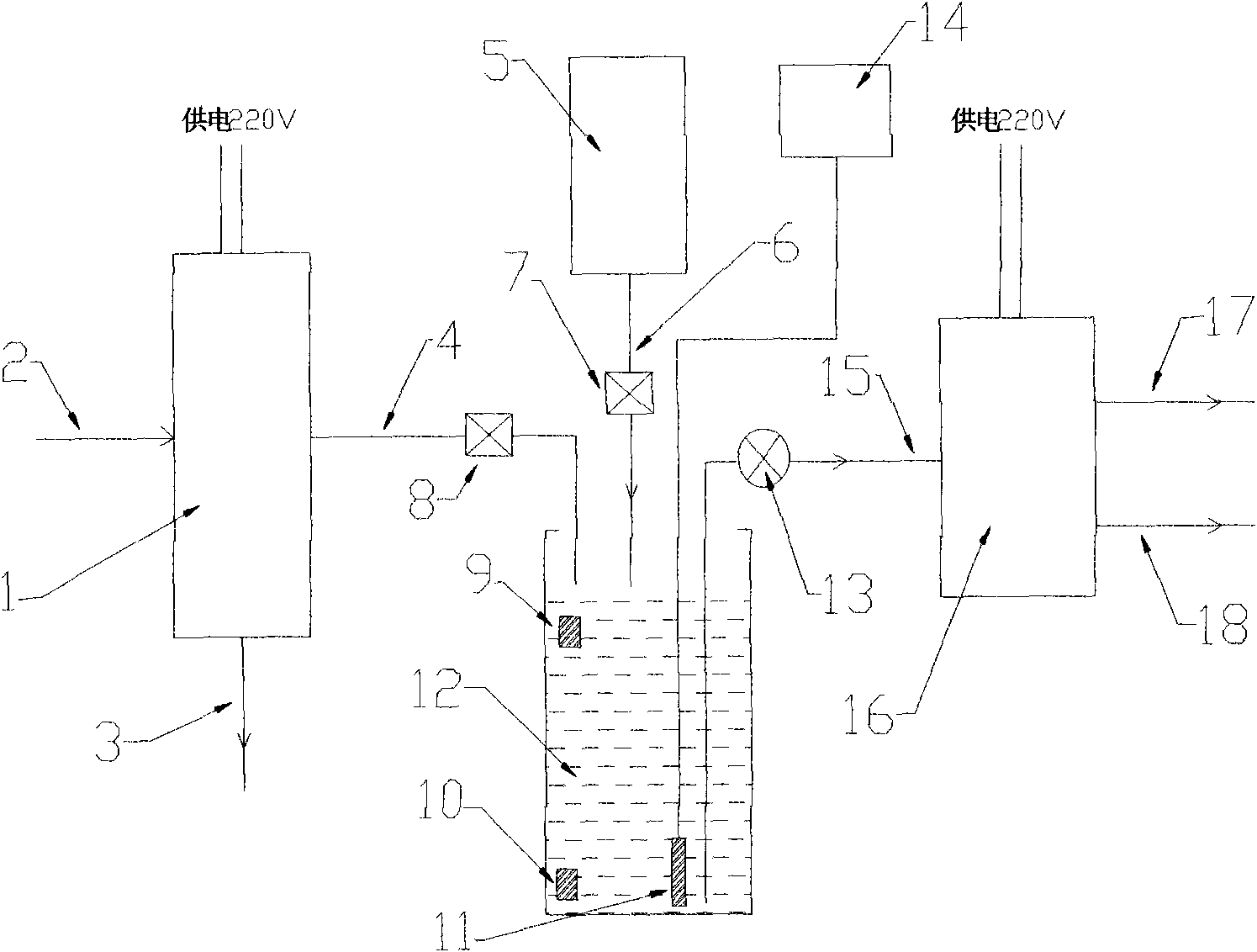

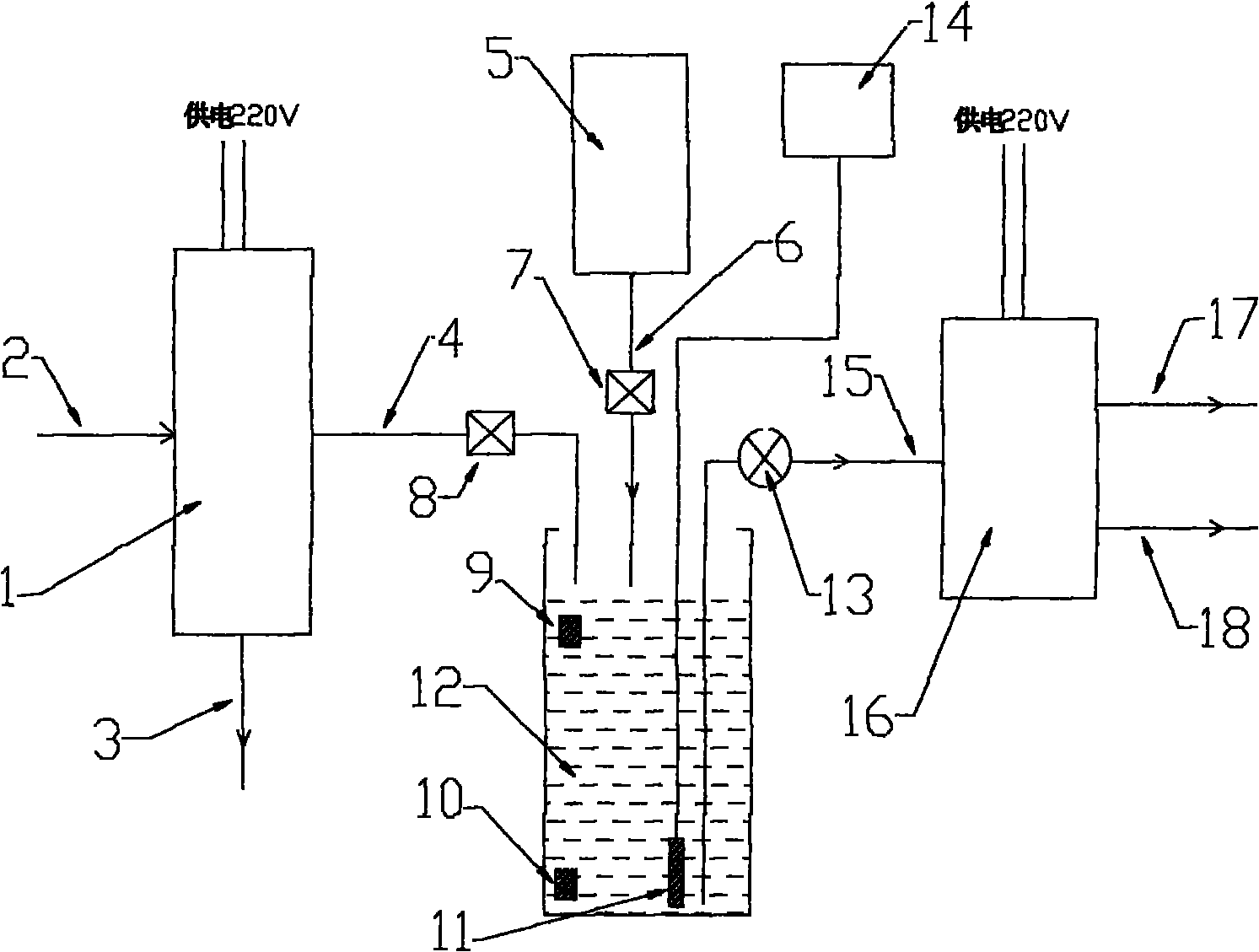

[0024] figure 1 Show the overall structure of the production equipment of this embodiment

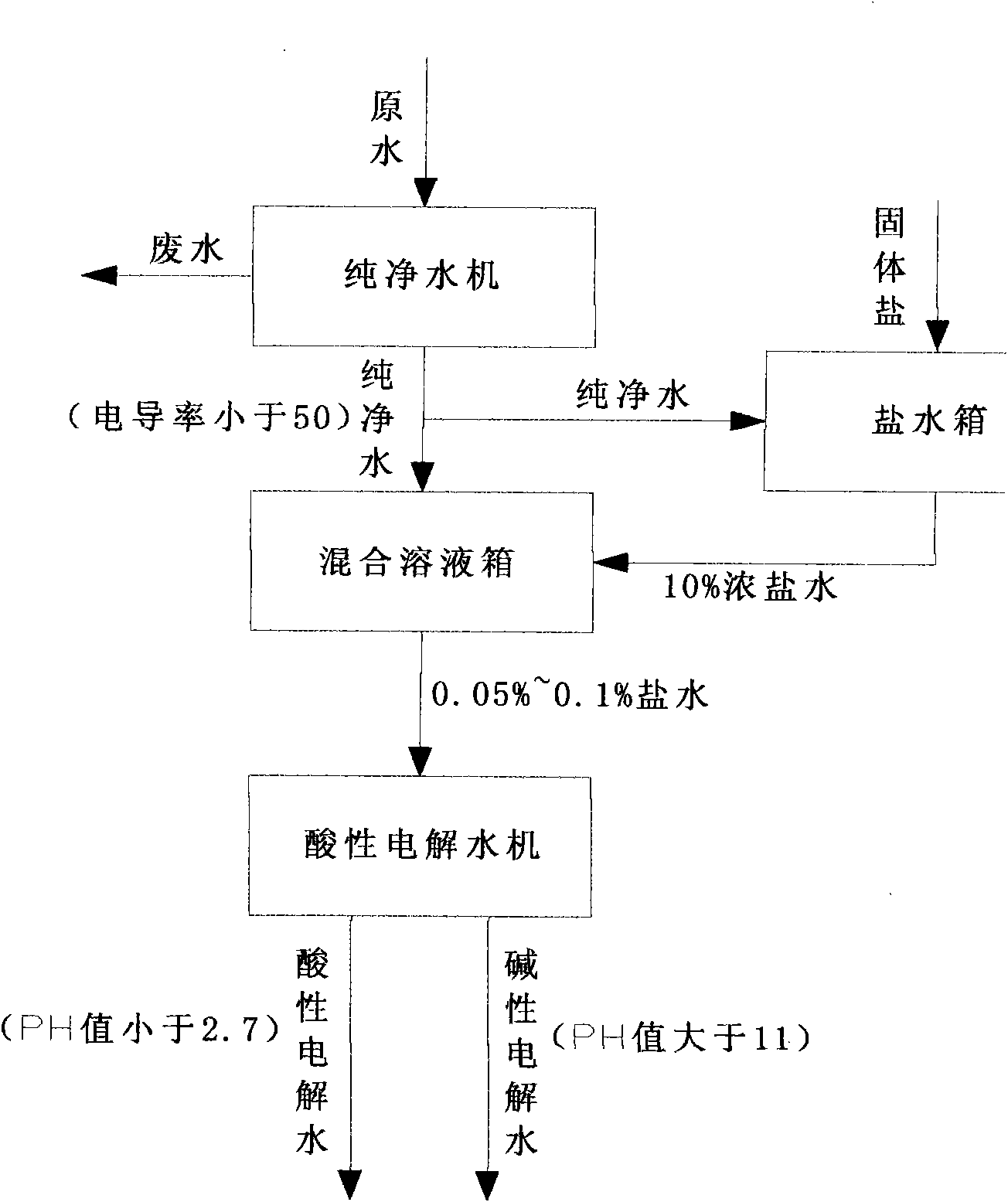

[0025] This embodiment is mainly composed of a pure water machine 1, a brine tank 5, a mixed solution tank 12 and an acidic electrolyzed water machine 16.

[0026] First; the raw water is made into pure water through the pure water machine 1; then the pure water and salt are put into the brine tank 5 at the same time, and the salt is diluted to make concentrated brine; the pure water and the concentrated brine are respectively put into the mixed solution tank 12 In the process, the concentrated brine is diluted into light brine that can make acidic water; the light brine is sucked into the acidic electrolyzed water machine 16 by the water pump 13 for electrolysis. Acidic electrolyzed water and alkaline electrolyzed water can be produced at the same time.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com