High strength square steel structured rubber composite manhole cover and preparation methods

A composite material, high-strength technology, used in underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as detrimental city appearance, subsidence of manholes, and lack of simultaneous improvement of manholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0055] [The first type] is a high-strength square steel structure rubber composite manhole cover;

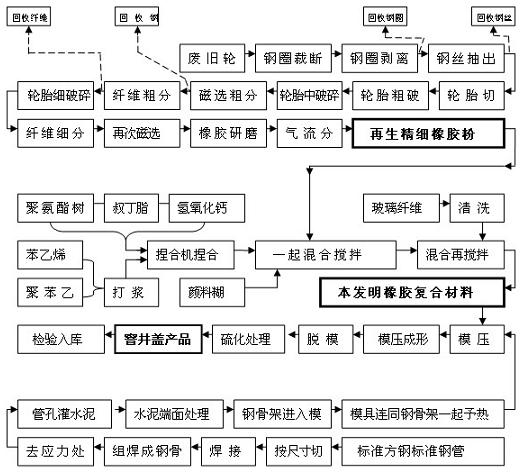

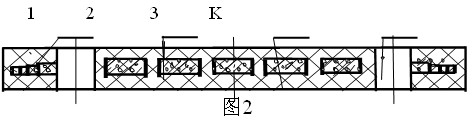

[0056] refer to Figure 2 ~ Figure 3 , a high-strength square steel structure rubber composite manhole cover composed of rubber composite material 1, square steel skeleton 2, and reinforced composite cement 3, the key technology is:

[0057] A. Reinforced composite cement (reinforced) is poured into the hole of the welded square steel skeleton;

[0058] B. The shape of the square steel skeleton is similar to a "shoulder pole", and the lower flat ends are pointed at both ends ("equal strength").

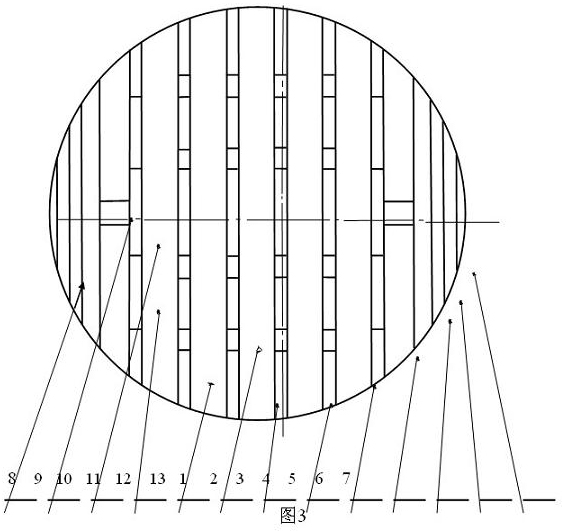

[0059] The required materials refer to image 3 , the standard square steel has:

[0060] 30mm×60mm×2mm ( image 3 1, 2, 3 in );

[0061] 30mm×50mm×2mm ( image 3 4 in );

[0062] 30mm×30mm×2mm ( image 3 5 of );

[0063] 30mm×20mm×2mm ( image 3 6, 7, 10, 12 in );

[0064] A total of four specifications of square steel materials and 30mm × 3mm flat iron.

[0065] Since the ...

Embodiment example 1

[0094] Implementation Case 1 , which will be described in detail below in combination with specific implementation cases:

[0095] 30 parts of polyurethane resin (the following formulas are all "unit weight parts"), 15 parts of glass fiber, 4.5 parts of polystyrene, 4.5 parts of styrene, 0.15 parts of tert-butyl fat, 0.15 parts of calcium hydroxide, 1 part of stearic acid 1 part, 1 part of zinc stearate, 60 parts of regenerated fine rubber powder, and 0.2 part of color paste.

[0096] Among the above raw materials, polyurethane resin is colloidal solvent type, polystyrene is granular, styrene is solvent type, tert-butyl fat is solvent type, calcium hydroxide is powder, stearic acid is powder, and regenerated fine rubber powder is powder (120 mesh), the color paste is a paste, and the length of the glass fiber is 4 to 8 cm. It is worth noting that during the manufacturing process of glass fiber, there is oily agent coated on the surface, which will hinder the bonding between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com