System and method for locating ultra-deepwater underwater stand pipe supporting pontoon

A technology for positioning systems and buoys, which is applied to underwater structures, underwater operating equipment, barges/flat-bottomed boats, etc. It can solve the problems of high risk factor, unsuitability in deep sea, and poor controllability of the position of support buoys in water. To achieve the effect of staying steadily and reducing the range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings.

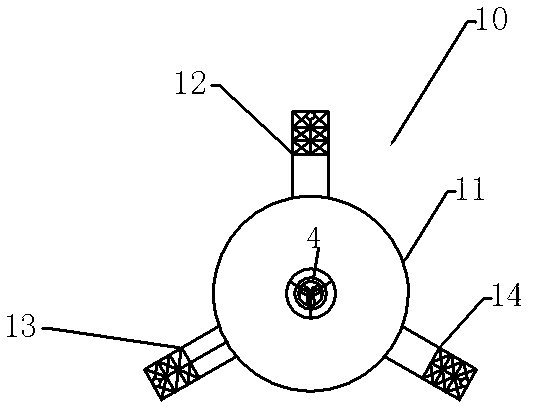

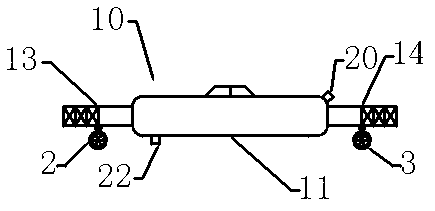

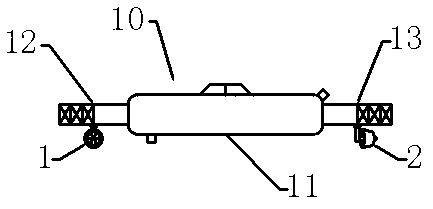

[0029] like figure 1 As shown, the riser support buoy 10 is composed of a central column structure buoy 11 and three cantilever buoys with a rectangular cross-section. The three cantilever buoys are located at the edge of the central column structure buoy 11, and the included angle on the plane is 120°, forming a radial shape. The three cantilever buoys are cantilever buoys A12, cantilever buoys B13 and cantilever buoys C14, and the ends of the three cantilever buoys adopt a truss structure with neutral buoyancy, so that the riser support buoy 10 in the water meets the pre-designed buoyancy, lowering the vertical buoyancy. The tubes support the weight of the pontoon 10, thereby reducing production costs.

[0030] like figure 2 As shown, the riser support buoy 10 has a umbilical interface 20 on the upper part and an exhaust valve 22 on the lower part.

[0031] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com