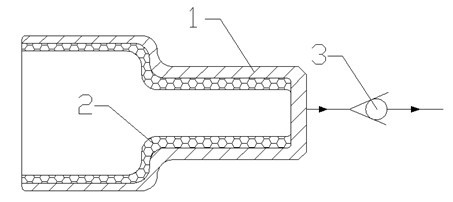

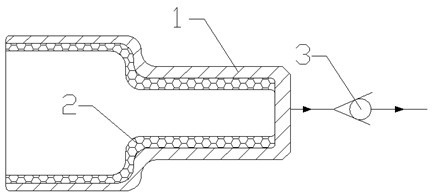

Thermal-shrinkage-type insulation anode exhaust sealing cap and preparation method thereof

A heat-shrinkable, heat-shrinkable layer technology, applied in the direction of electrical components, cable/conductor manufacturing, power cables, etc., can solve problems such as moisture cannot be excluded, and achieve the effects of easy installation, high flame retardancy, and good waterproof and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh: 20 parts of ethylene vinyl acetate, 80 parts of high-pressure low-density polyethylene, stir and mix evenly to obtain the polyolefin mixed resin of the present invention.

[0041] Weigh: 30 parts of magnesium hydroxide, 60 parts of aluminum hydroxide, and 5 parts of coated red phosphorus, stir and mix evenly to obtain the halogen-free composite flame retardant of the present invention.

[0042] Weigh: 20 parts of 1010 antioxidant, 20 parts of AMPTMA sensitizer, 20 parts of 303 brightener, stir and mix evenly to obtain other additives of the present invention.

[0043] Weigh 40 parts of the above-mentioned polyolefin mixed resin, 30 parts of halogen-free composite flame retardant, and 15 parts of other additives, mix the polyolefin mixed resin, halogen-free composite flame retardant and other additives evenly, melt and co- Mixing, the particles are obtained by a single-screw extruder; the prepared particles are injection-molded by an injection molding machine; the...

Embodiment 2

[0047] Weigh: 30 parts of ethylene vinyl acetate, 70 parts of high-pressure low-density polyethylene, stir and mix evenly to obtain the polyolefin mixed resin of the present invention.

[0048] Weigh: 50 parts of magnesium hydroxide, 40 parts of aluminum hydroxide, and 10 parts of coated red phosphorus, stir and mix evenly to obtain the halogen-free composite flame retardant of the present invention.

[0049] Weighing: 10 parts of 1010 antioxidant, 30 parts of sensitizer triallyl isocyanurate, brightener di(2,2,6,6-tetramethyl-3-piperidinylamino)-m 10 parts of phthalamide, stir and mix evenly to obtain other additives of the present invention.

[0050] By weighing 50 parts of the above-mentioned polyolefin mixed resin, 25 parts of halogen-free composite flame retardant, and 25 parts of other additives, the method described in Example 1 can be used to obtain the heat-shrinkable insulating anode vent cap of the present invention.

Embodiment 3

[0052] Weigh: 25 parts of ethylene vinyl acetate, 75 parts of high-pressure low-density polyethylene, stir and mix evenly to obtain the polyolefin mixed resin of the present invention.

[0053] Weigh: 40 parts of magnesium hydroxide, 50 parts of aluminum hydroxide, and 8 parts of coated red phosphorus, stir and mix evenly to obtain the halogen-free composite flame retardant of the present invention.

[0054]Weigh: 15 parts of 1010 antioxidant, 25 parts of AMPTMA sensitizer, 15 parts of 303 brightener, stir and mix evenly to obtain other additives of the present invention. Obviously, in the present invention, the sensitizer and brightener can also be selected from other raw materials commonly used in this industry as mentioned above, which will not affect the performance of the final product.

[0055] By weighing 45 parts of the above-mentioned polyolefin mixed resin, 28 parts of halogen-free composite flame retardant, and 21 parts of other additives, the method described in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com