Low-pressure fusing disconnecting switch

An isolating switch and fuse type technology, applied in electrical components and other directions, can solve the problems of safety hazards, short service life, high use and maintenance costs, cumbersome replacement of fuses, etc. The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

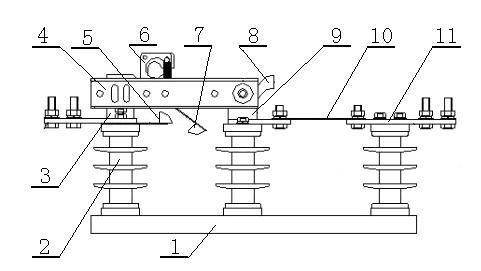

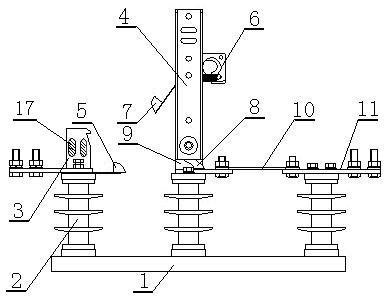

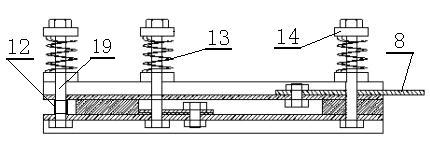

[0027] Embodiment 1: As shown in the accompanying drawings, the low-voltage fuse type isolating switch of the present invention includes a base 1, a silicon rubber insulator support 2, a knife switch installed on the silicon rubber insulator support 2, a metal wire 10, a terminal block 11 and an anti- arc device. The base 1 is a "︱"-shaped mounting plate, and three silicone rubber insulator posts 2 are installed on the base 1, of which two silicone rubber insulator posts 2 are respectively equipped with moving contacts 3 and static contacts 9, and the other silicone rubber insulator posts 2 The wiring board 11 is installed, and the wiring board 11 is connected with the static contact 9 through the wire 10 . The knife switch includes a moving contact 3, a static contact 9, two knife plates 4, a pull ring 6 and a pressure spring 13; There is a circular concave contact surface 18, and the moving contact 3 and the static contact 9 are respectively installed on the corresponding s...

Embodiment 2

[0028] Embodiment 2: As shown in the accompanying drawings, the low-voltage fuse type isolating switch of the present invention includes a base 1, a silicon rubber insulator support 2, a knife switch installed on the silicon rubber insulator support 2, a metal sheet 10, a terminal block 11 and an anti- arc device. The base 1 is a "︱"-shaped mounting plate, and three silicone rubber insulator posts 2 are installed on the base 1, of which two silicone rubber insulator posts 2 are respectively equipped with moving contacts 3 and static contacts 9, and the other silicone rubber insulator posts 2 The wiring board 11 is installed, and the wiring board 11 is connected with the static contact 9 through the metal sheet 10 . Knife switch comprises moving contact 3, static contact 9, two blade plates 4, pull ring 6 and compression spring 13; There is a circular concave contact surface 18, and the moving contact 3 and the static contact 9 are respectively installed on the corresponding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com