Membrane feeding device on gas analysis mass spectrometer

A technology of gas analysis and mass spectrometer, which is applied to the parts of particle separator tubes, sample introduction/extraction, etc., which can solve the problems of reduced mass spectrometry sensitivity, small membrane area, inconvenient replacement, etc., to avoid frequent damage, save time and The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

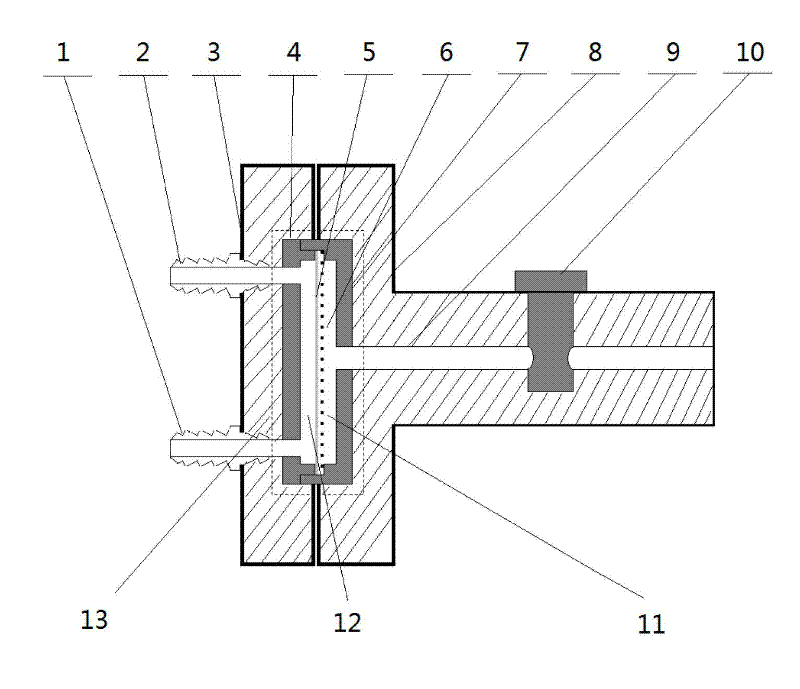

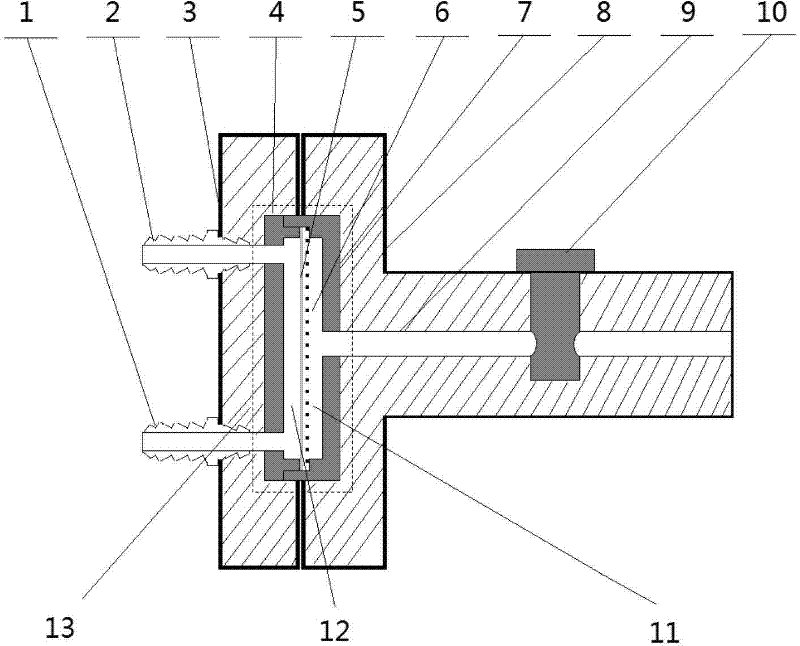

[0020] refer to figure 1 , the film sampling device on the gas analysis mass spectrometer of the present invention comprises a pressure film box 13, a front connecting flange 3 and a rear connecting flange 8, and the front connecting flange 3 and the rear connecting flange 8 are all provided with a Groove, the pressure film box 13 is closely matched between the front end connection flange 3 and the rear end connection flange 8 through the groove, and the pressure film box 13 is composed of a pressure film box cover 4, a film 5, a support net 6, The film box body 7 is composed of the film box cover 4 and the film box body 7, and the film 5 and the support net 6 are pressed in between. The space between the film box cover 4 and the film 5 constitutes the sample chamber 12. The space between the net 6 and the lamination box body 7 constitutes a buffer chamber 11 .

[0021] There are two circular through holes in the groove of the front connecting flange 3, the inner diameter is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com