Sterilisation of packaged articles

A packaging and product technology, applied in packaging sterilization, food preservation, water supply equipment, etc., can solve problems such as expensive and difficult to control, and achieve the effect of long life, reliability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

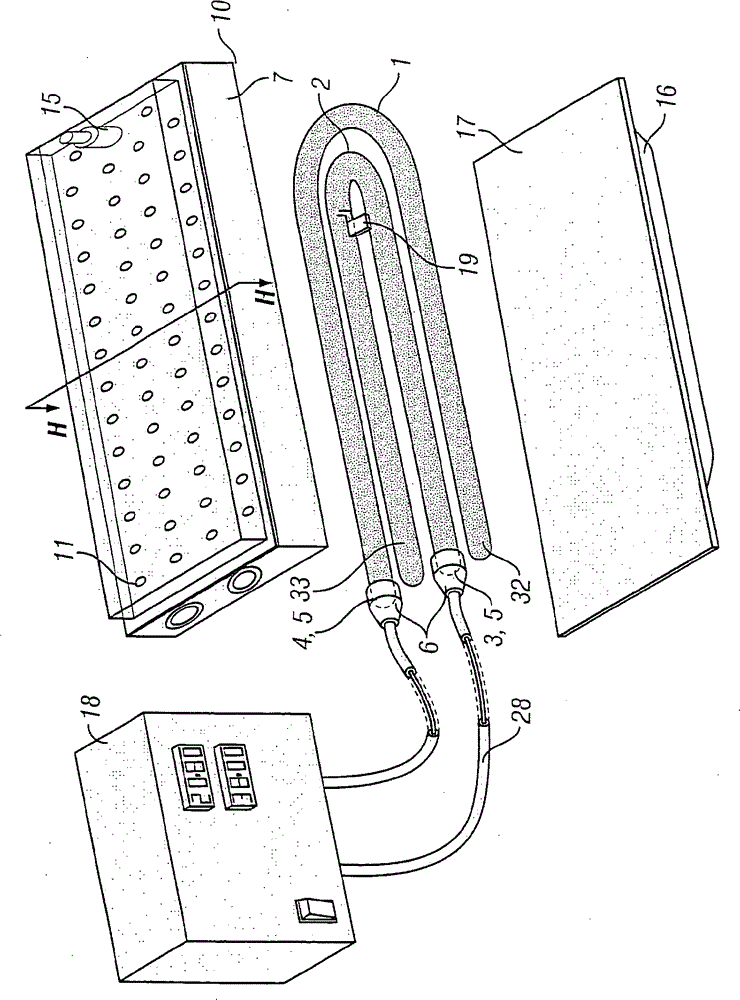

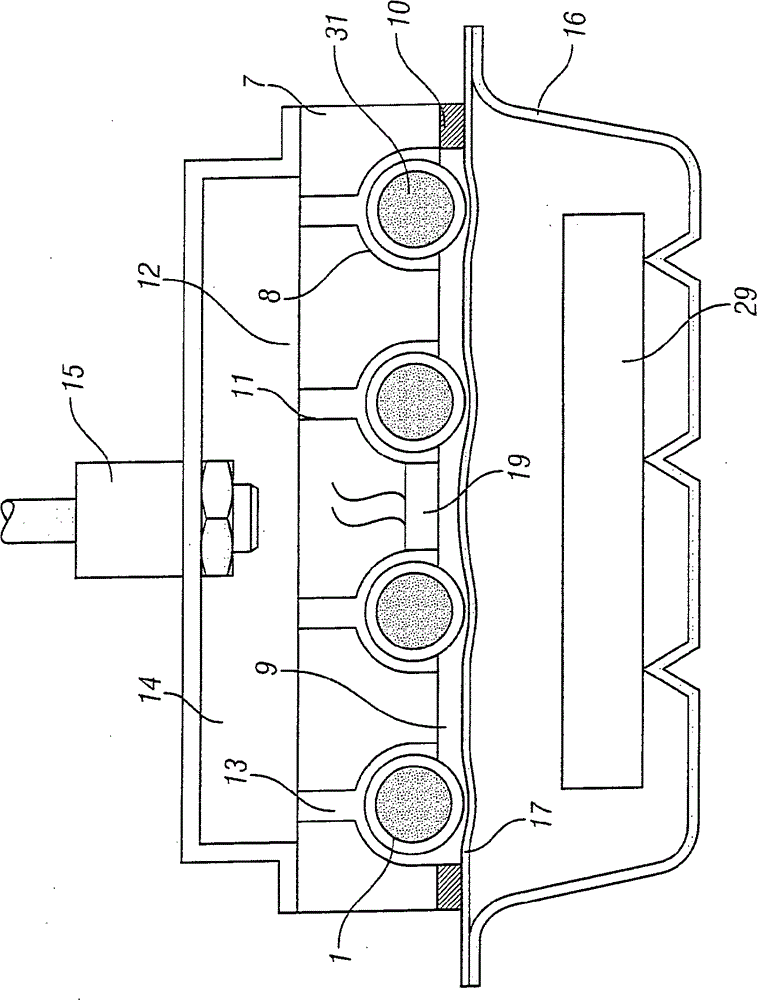

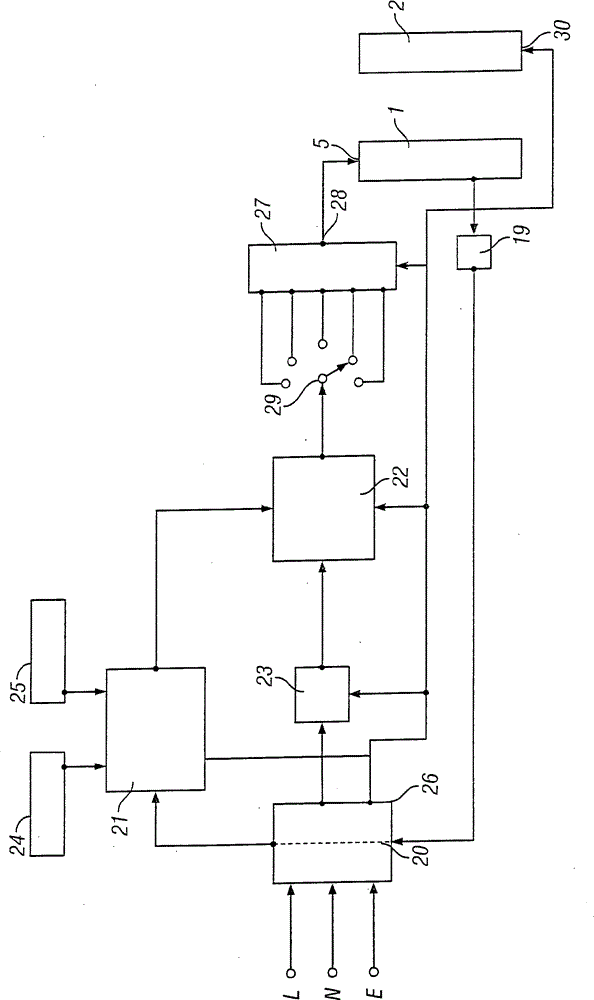

[0052] about the attached figure 1 and 2 , shows a sterilization device comprising two flat U-shaped discharge vessels 1, 2 formed of a non-conductive material such as glass. The tubes 1, 2 extend side by side along their length and are separated by a substantially uniform gap.

[0053] The interior 31 of the tubes 1, 2 is filled with an inert gas such as neon or another ionizable gas under partial vacuum. The tubes 1,2 are hermetically sealed at both ends 3,32 and 4,33. On one end of each tube 1 , 2 a metal contact 5 is included which is covered by an insulator 6 to provide means for connecting a high voltage power supply 18 via a wire 28 which is connected to the metal contact 5 through the insulator 6 .

[0054] The discharge tubes 1 , 2 are mounted against a reflector 7 having a front surface that outlines the receiving tubes 1 , 2 . A portion of reflector 7 extends between each tube. The reflector 7 is made of a ferromagnetic material such as ferrite or ferrite powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com