Power tool

A power tool and working head technology, applied in the field of oscillating power tools, can solve the problems of low oscillating frequency and low work efficiency, and achieve the effect of increasing oscillating frequency, improving work quality and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

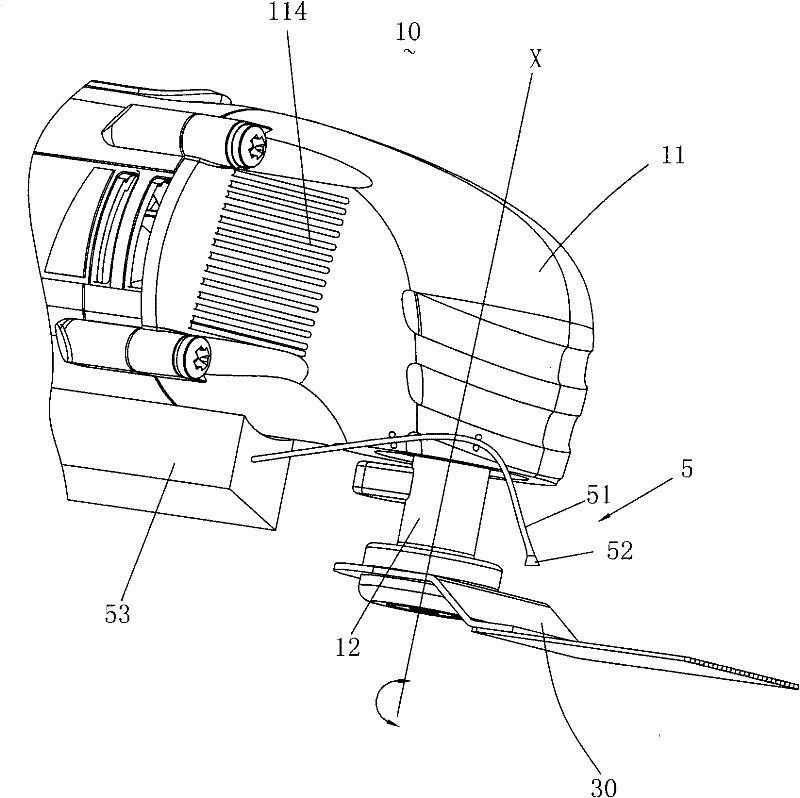

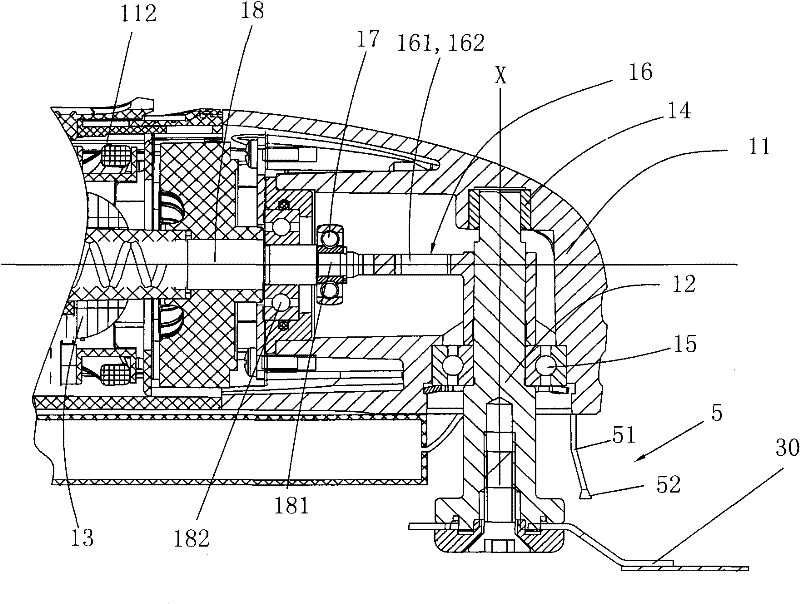

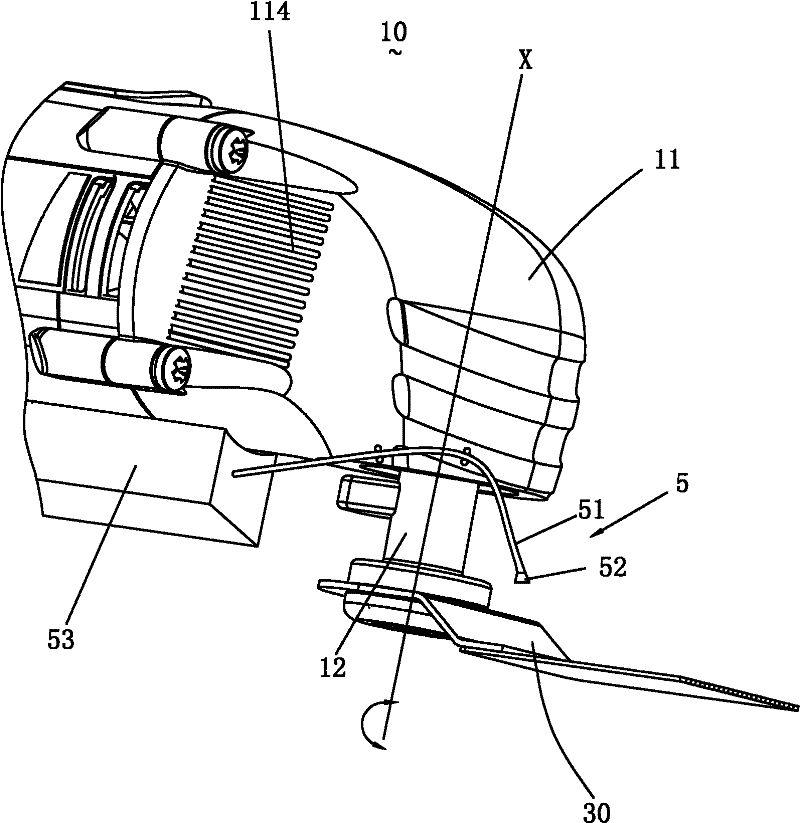

[0030] see Figure 1 to Figure 2 , a power tool 10, the power tool 10 of the present embodiment is a swinging machine, which includes a housing 11 that is arranged approximately in an angle, and a motor 13 is arranged inside the housing 11, the motor 13 has a motor shaft 18, and the motor bearing 182 supports the motor shaft 18. The bearing 182 can be an ordinary ball bearing, preferably a bearing with low friction and high temperature resistance while providing a very high speed, such as an air bearing, a hydraulic bearing, etc. These bearings use gas or The liquid acts as a lubricant with low resistance, allowing higher rotational speeds while maintaining a low vibration level; less resistance results in less friction, less power loss and less heat generation, resulting in less temperature rise. Of course, not only the motor shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com