Manufacturing method for compound of metal and resin

A manufacturing method and complex technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of unfavorable environmental protection, difficult handling of etching solution, etc., and achieve the effect of enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

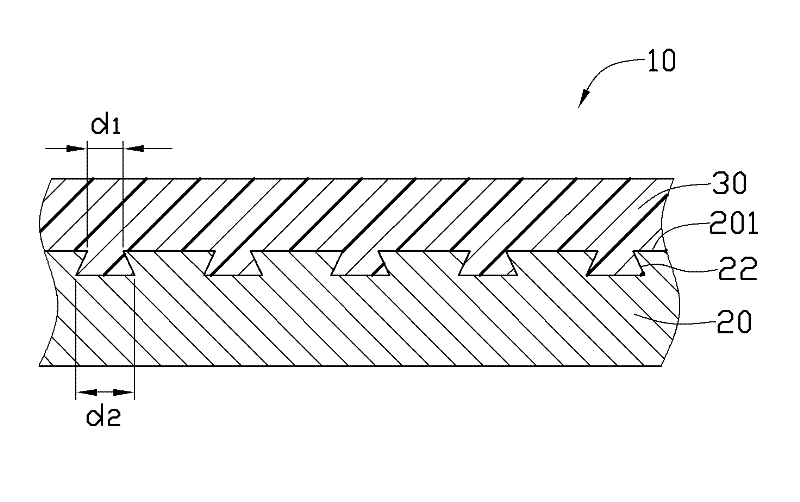

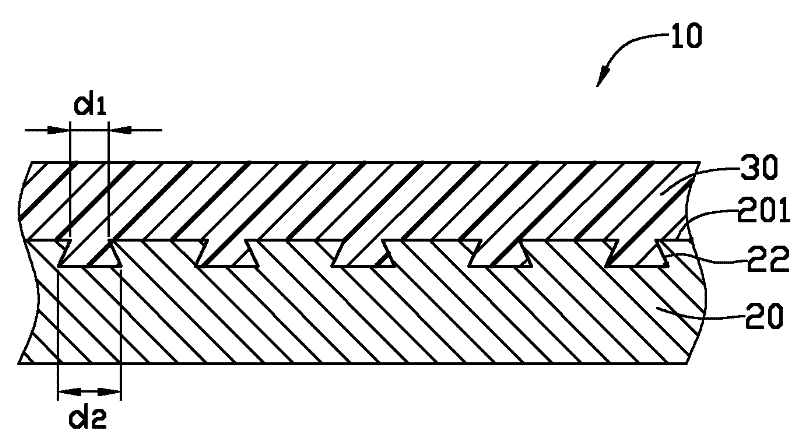

[0022] see figure 1 , The metal-resin composite body 10 of the preferred embodiment of the present invention includes a metal part 20 and a resin part 30 combined with the metal part.

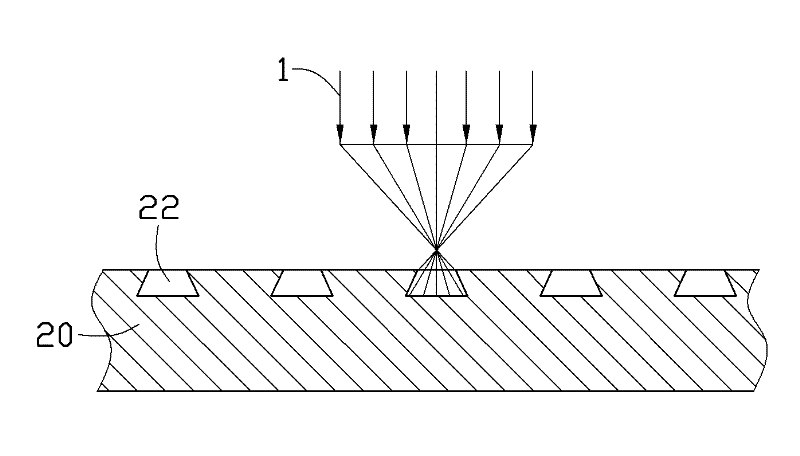

[0023] The surface 201 of the metal piece 20 is formed with several micropores 22, and the opening diameter d of the micropores 22 is 1 smaller than the hole bottom diameter d 2 , where the opening diameter d 1 It is about 5-50 microns, and the depth is about 25-300 microns. The material of the metal parts can be aluminum alloy, magnesium alloy, stainless steel, copper and copper alloy.

[0024] The resin part 30 is partly intruded into the micropore 22 to combine with the metal part 20 by means of injection or thermal fusion. The resin member 30 is composed of a crystalline thermoplastic resin, which may be a mixture of polyphenylene sulfide (PPS) and glass fiber, polyamide (PA), polyethylene terephthalate (PET), or polyethylene terephthalate (PET). Butylene Terephthalate (PBT). If it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com